Coal ore rapid float-and-sink testing device and application method thereof

A technology for floating and sinking tests and ores, which is applied in chemical instruments and methods, preparation of test samples, wet separation, etc., can solve problems such as test errors, time-consuming and labor-intensive changes, etc., achieve high test efficiency, avoid artificial addition, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

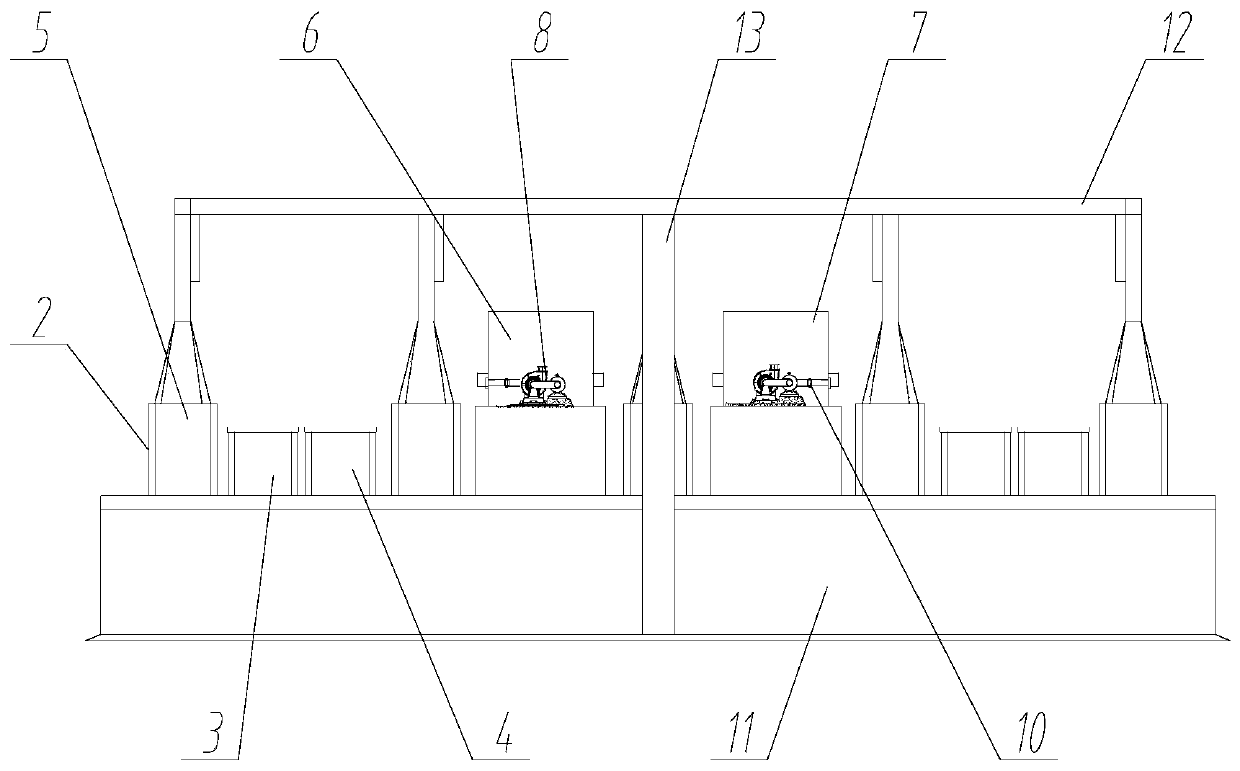

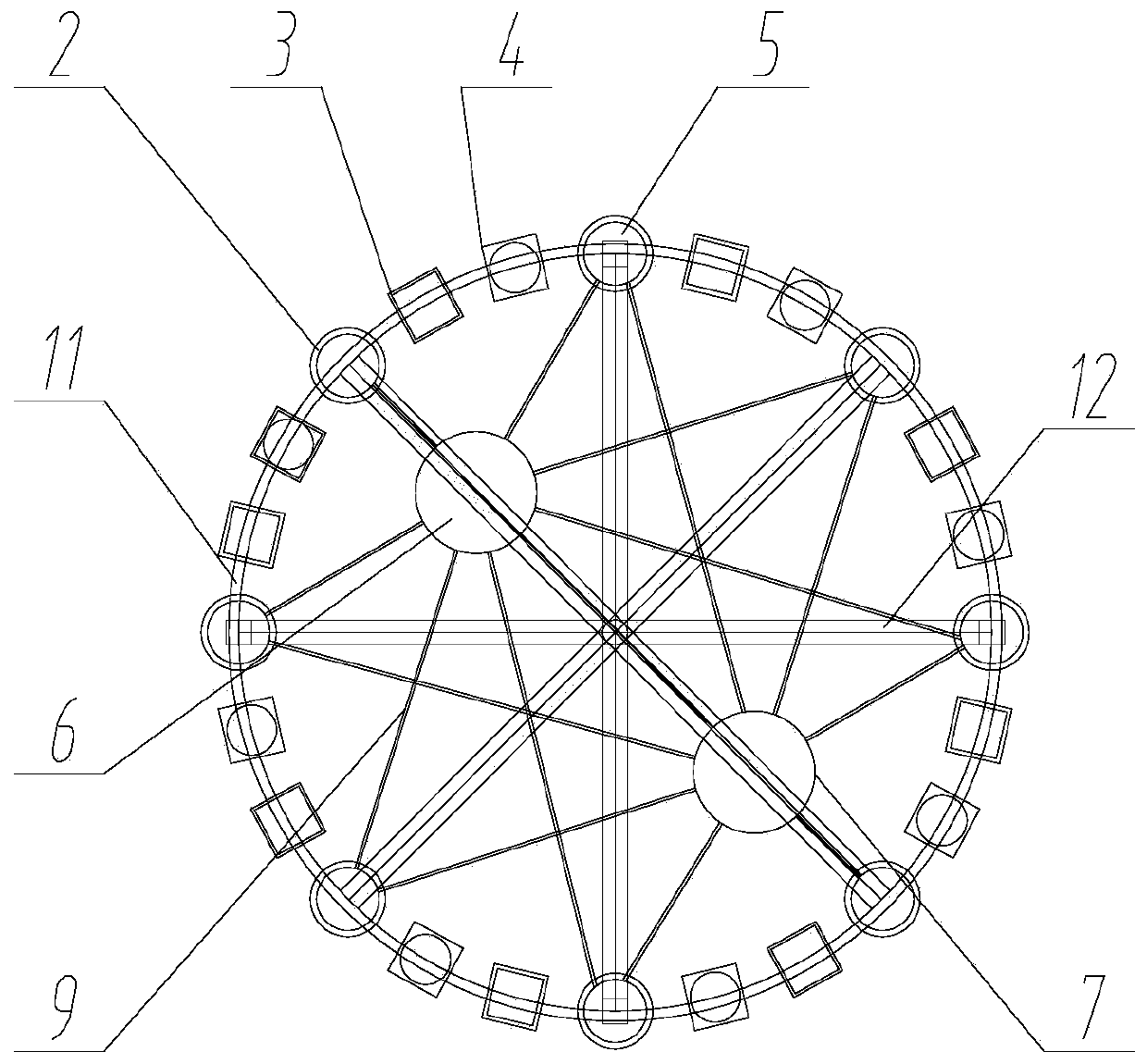

[0029] Such as figure 1 , figure 2 Shown, this a kind of coal ore fast floating and sinking test device comprises rotating assembly, annular support 11 and bucket assembly;

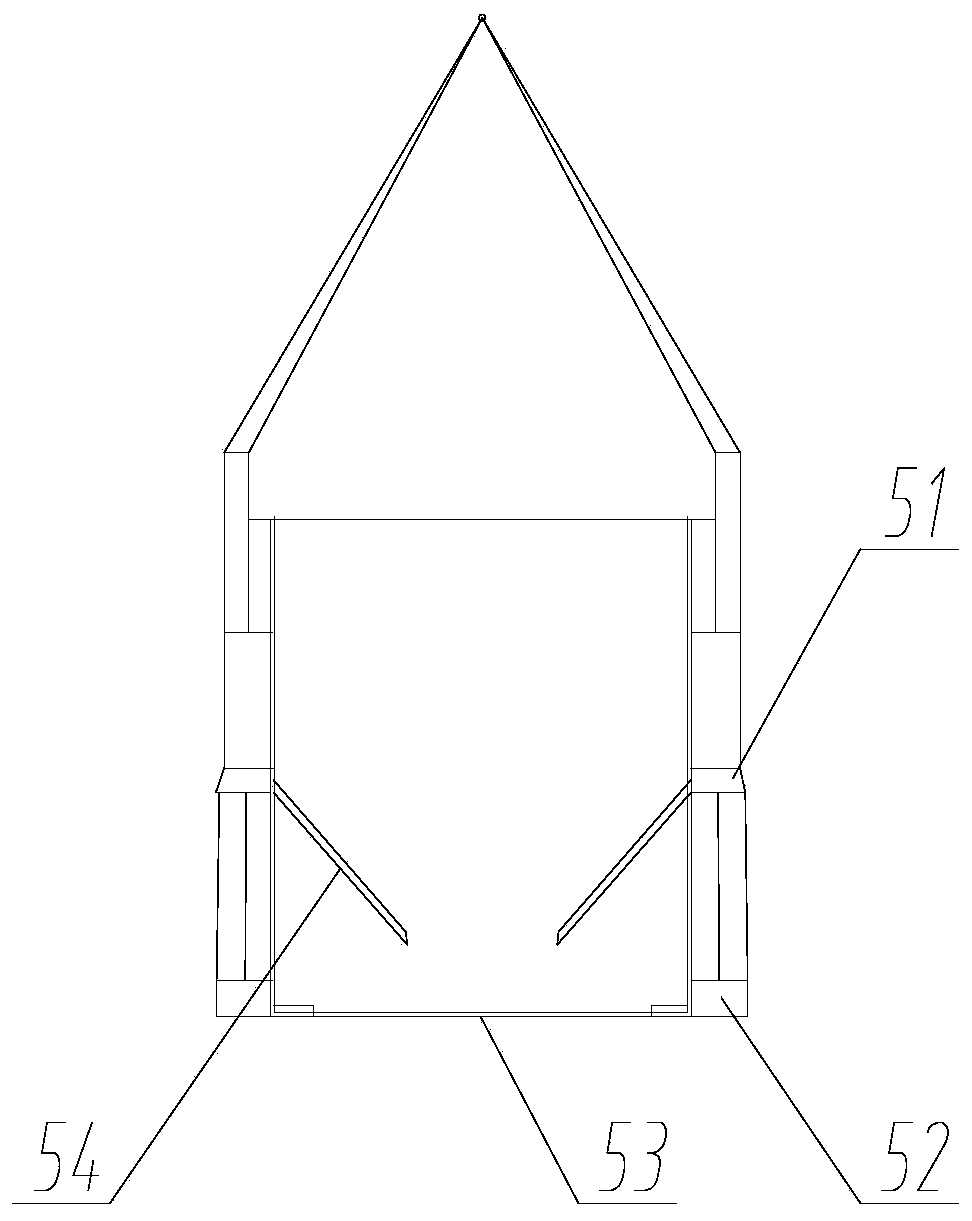

[0030] The rotating assembly includes a rotating main shaft 13 that lifts up and down and rotates in a circle, and a cantilever 12 that is horizontally arranged on the upper end of the rotating main shaft 13, and the lower end of the cantilever 12 is hoisted with a net bottom bucket 5 for opening and closing liquid separation;

[0031] The bucket assembly is arranged on the annular support 11 and includes a processing bucket assembly and a liquid replenishment bucket assembly; the processing bucket assembly includes a heavy liquid bucket 2 with different densities, a sink collection bucket 3 and a float collection bucket 4; the heavy liquid bucket 2. The sinki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com