Biological valve with anticoagulation and anti-calcification functions and preparation method thereof

A biological valve and anticoagulation technology, applied in the field of medical materials and medical device preparation, can solve problems such as coagulation of interventional pulmonary valve, improve long-term anticoagulation and anticalcification performance, eliminate immunogenicity, reduce coagulation and calcification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a biological valve with anticoagulant and anticalcification functions, the specific process is:

[0034] (1) After cleaning the porcine pericardial valve with deionized water, soak it in an aqueous solution of 0.5% glucosamine and 1% condensing agent at 4°C for 2 days;

[0035] (2) Soak in 1% glutaraldehyde solution at 4°C for 7 days;

[0036] (3) Soak in 3% taurine aqueous solution at 4° C. for 2 days to obtain the target biological valve material.

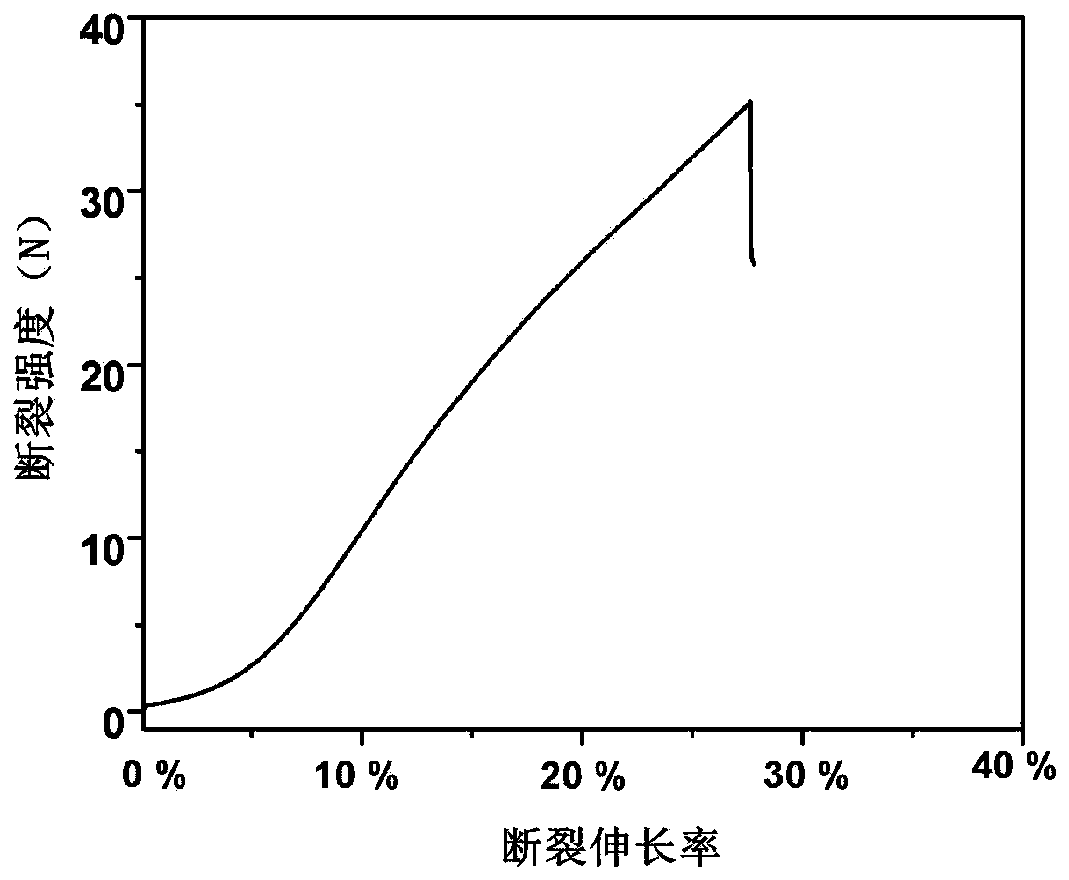

[0037] The tensile fracture stress of the anti-calcification biological heart valve prepared in this implementation is 36N under the uniaxial tensile test (1*5cm sample size).

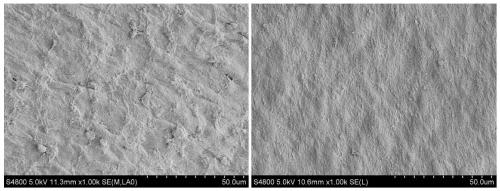

[0038] The platelet adhesion experiment found that the biovalve prepared in this implementation has significantly improved anticoagulant performance compared with the traditional glutaraldehyde cross-linked valve.

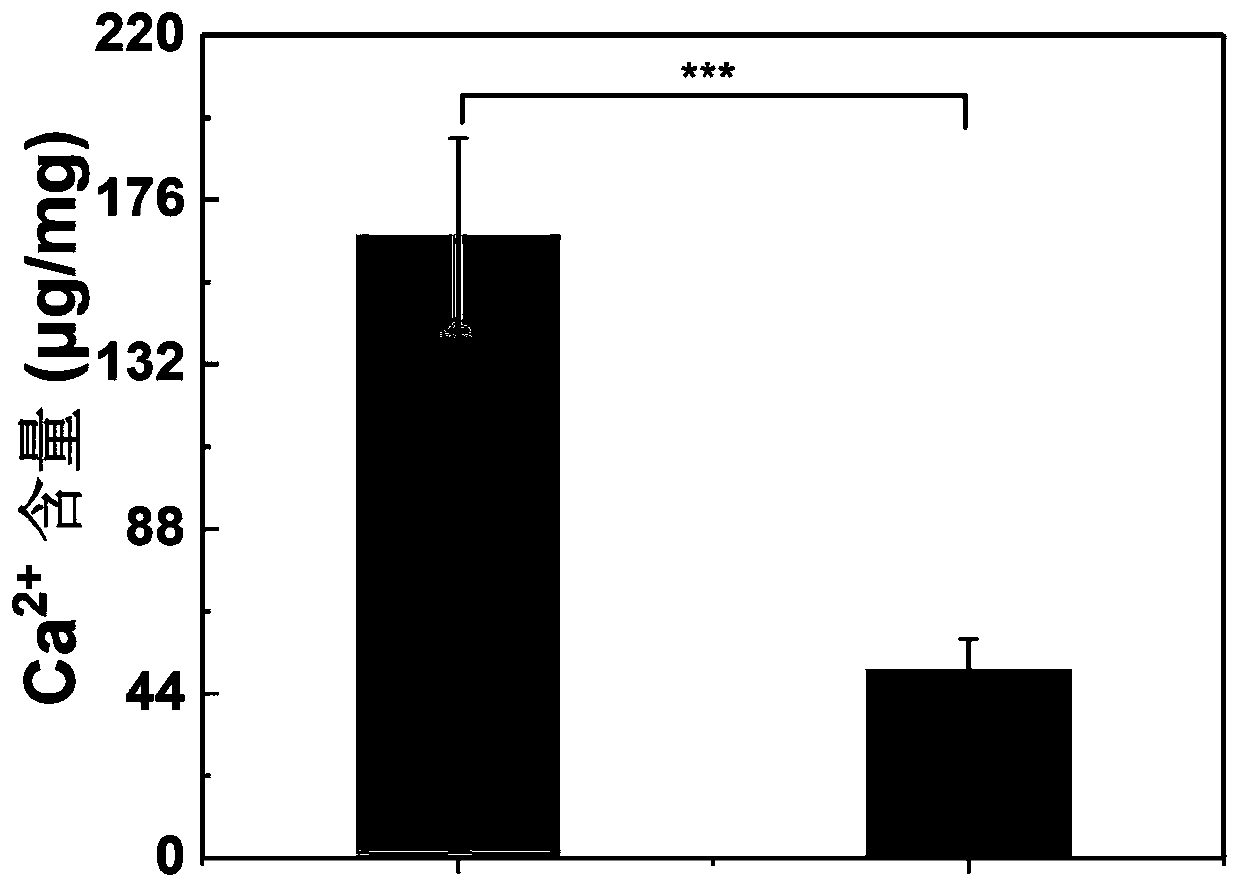

[0039] The experiment of subcutaneous implantation in rats found that the anti-calcification effect of the bi...

Embodiment 2

[0041] A method for preparing a biological valve with anticoagulant and anticalcification functions, the specific process is:

[0042] (1) After the bovine pericardial valve is cleaned with deionized water, soak it in an ethanol aqueous solution of 1% perfluorooctanoic acid-2-aminoethyl ester and 3% condensing agent at 4°C for 2 days;

[0043] (2) Soak in 5% glutaraldehyde solution at 4°C for 7 days;

[0044] (3) Soak in 1% perfluorobutylamine ethanol aqueous solution at 4° C. for 2 days to obtain the target biological valve material.

[0045] The tensile fracture stress of the anti-calcification biological heart valve prepared in this implementation is greater than 30N under the uniaxial tensile test (1*5cm sample size).

[0046] The platelet adhesion experiment found that the biovalve prepared in this implementation has significantly improved anticoagulant performance compared with the traditional glutaraldehyde cross-linked valve.

[0047]The subcutaneous implantation exp...

Embodiment 3

[0049] A method for preparing a biological valve with anticoagulant and anticalcification functions, the specific process is:

[0050] (1) After cleaning the porcine pericardial valve with deionized water, soak it in a glutaraldehyde solution with a concentration of 3% for 7 days at 4°C;

[0051] (2) at 4°C, soak for 5 days in an aqueous ethanol solution with a concentration of 2% (2-aminoethyl)-perfluorooctylamide and a concentration of 5% condensing agent;

[0052] (3) Soak in 3% perfluorooctylamine ethanol aqueous solution at 4°C for 5 days to obtain the target biological valve material.

[0053] The tensile fracture stress of the anti-calcification biological heart valve prepared in this implementation is greater than 30N under the uniaxial tensile test (1*5cm sample size).

[0054] The platelet adhesion experiment found that the biovalve prepared in this implementation has significantly improved anticoagulant performance compared with the traditional glutaraldehyde cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com