Contactable intelligent plasma creeping discharge device

A surface discharge and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of high overall power consumption, unfavorable commercialization, single function, etc., and achieve the effect of avoiding power loss and good human-computer interaction experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

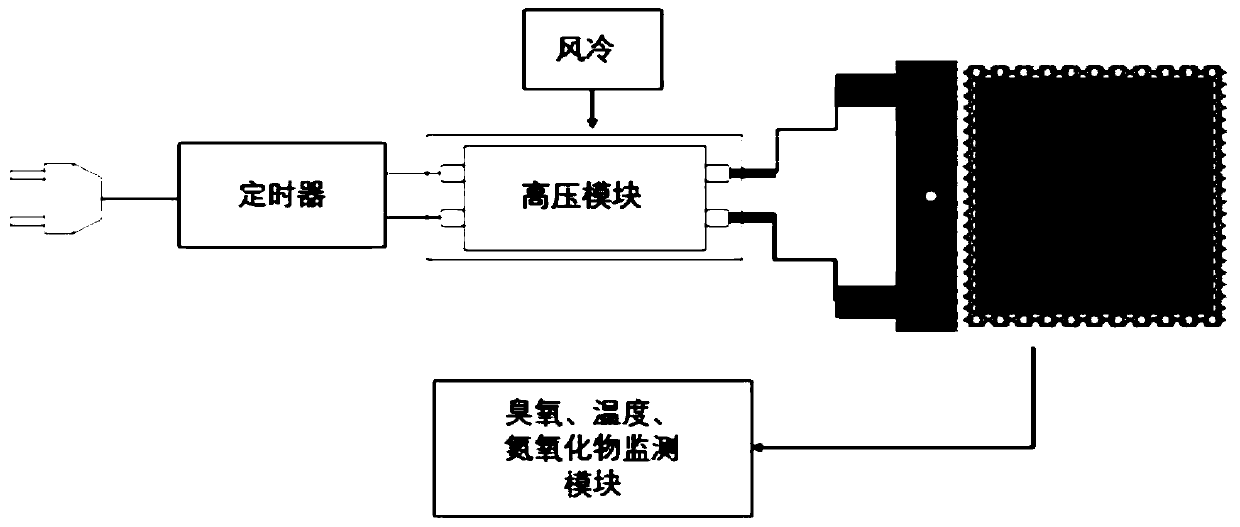

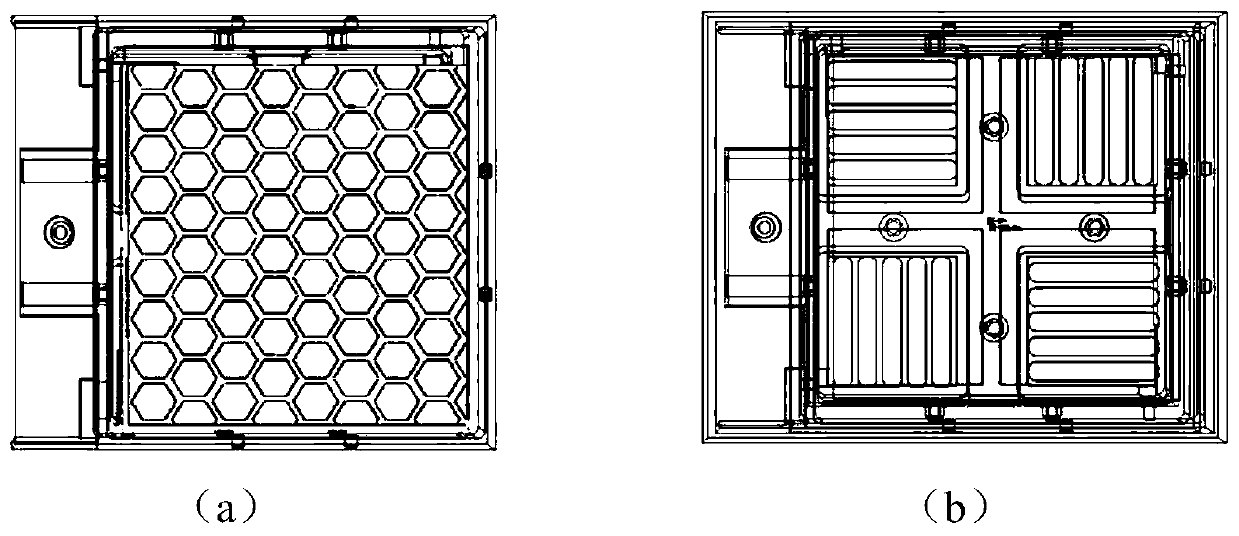

[0045] In this embodiment, the high-voltage module is used to drive the plasma generation module to generate plasma, and the temperature module with negative feedback is used to control the fan to dissipate heat for the high-voltage module. Sensors that can monitor the concentration and temperature of ozone and nitrogen oxides are installed in the device to monitor the discharge at all times. The product is used to monitor the discharge state, and finally a timer is installed at the 220V power supply end of the entire device to control the single working time of the contactable intelligent plasma surface discharge device.

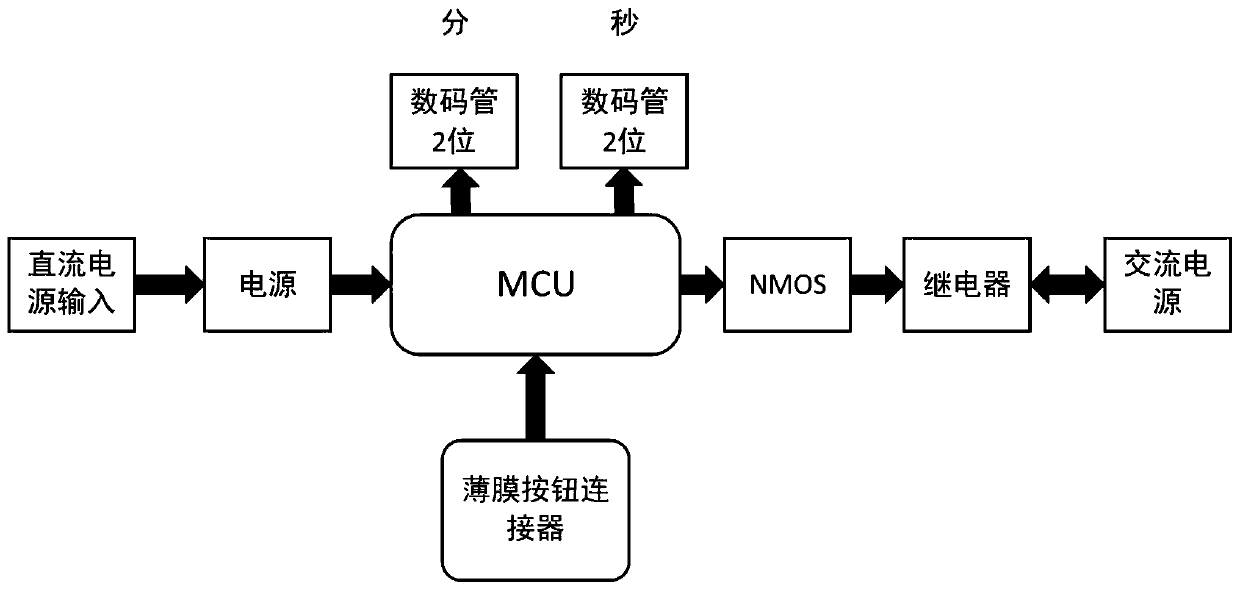

[0046] like figure 1 Shown is the connection schematic diagram of the contactable intelligent plasma surface discharge device. The whole device is divided into four parts: timer module, high voltage module (includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com