Foam nickel sand control screen pipe and manufacturing method thereof

A technology for sand control screen pipes and manufacturing methods, which is applied in the directions of earth drilling, ion implantation plating, mining fluids, etc., which can solve problems such as poor corrosion resistance, easy clogging, and short validity period, so as to improve oil production efficiency and prolong sand control operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

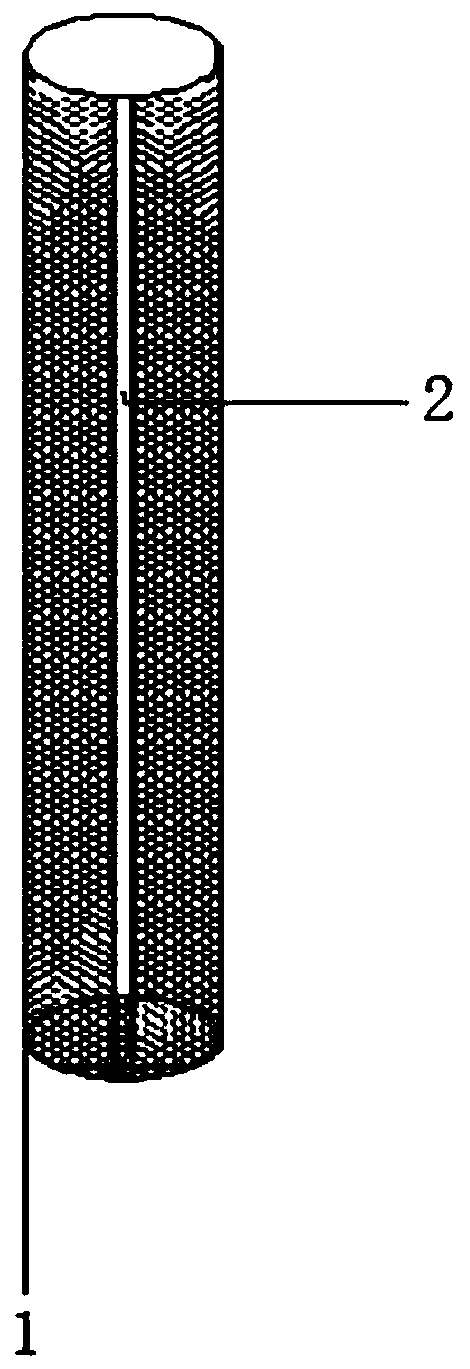

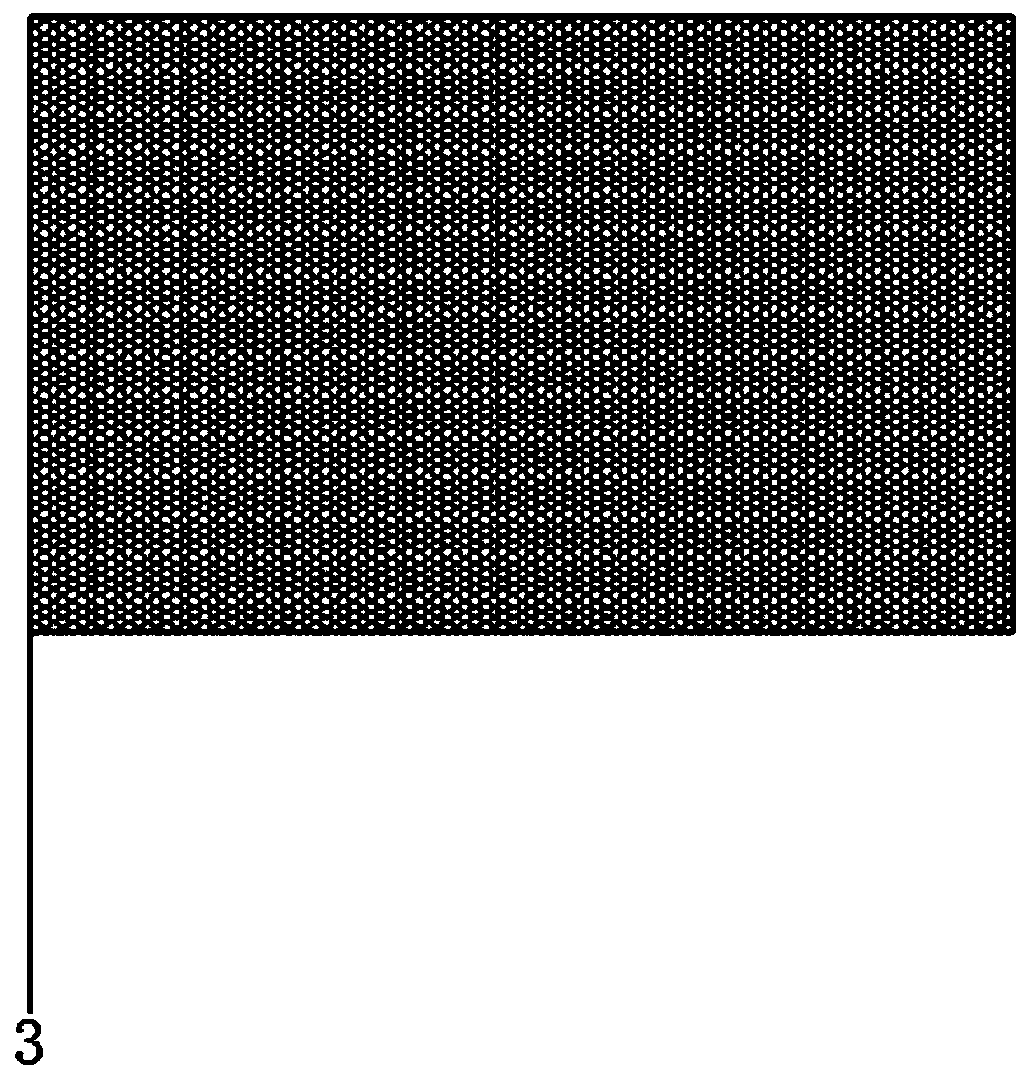

[0023] refer to figure 1 and figure 2 , The foamed nickel sand control screen 1 of this embodiment is formed by crimping and welding the foamed nickel metal sheet 3.

[0024] In this embodiment, the foamed nickel sand control screen 1 has an aperture of 80PPi and a bulk density of 2g / cm 3 .

[0025] In this embodiment, the nickel foam sand control screen 1 has a thickness of 8 mm, a height of 1000 mm, and a pipe diameter (inner diameter) of 180 mm. Of course, it can also be designed into products of other sizes, and the specific product size can be adjusted according to customer needs.

[0026] The preparation method comprises the following steps:

[0027] Deposit a layer of metallic nickel on the sponge by PVD (Physical Vapor Deposition), and then electroplate the sponge deposited with metallic nickel. After electroplating, wash with water until the washing liquid is clear, transparent and green, dry, and then incinerate in an incinerator Remove the inner layer of spong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com