Space dyeing equipment based on single-color printing and dyeing and application method thereof

A single-color, equipment-based technology, applied in the direction of textile material equipment configuration, textile material processing, and partial processing of textile materials, can solve problems such as low economic benefits, high maintenance costs, and increased product production costs, and achieve structural composition The effect of simplicity, low manufacturing cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

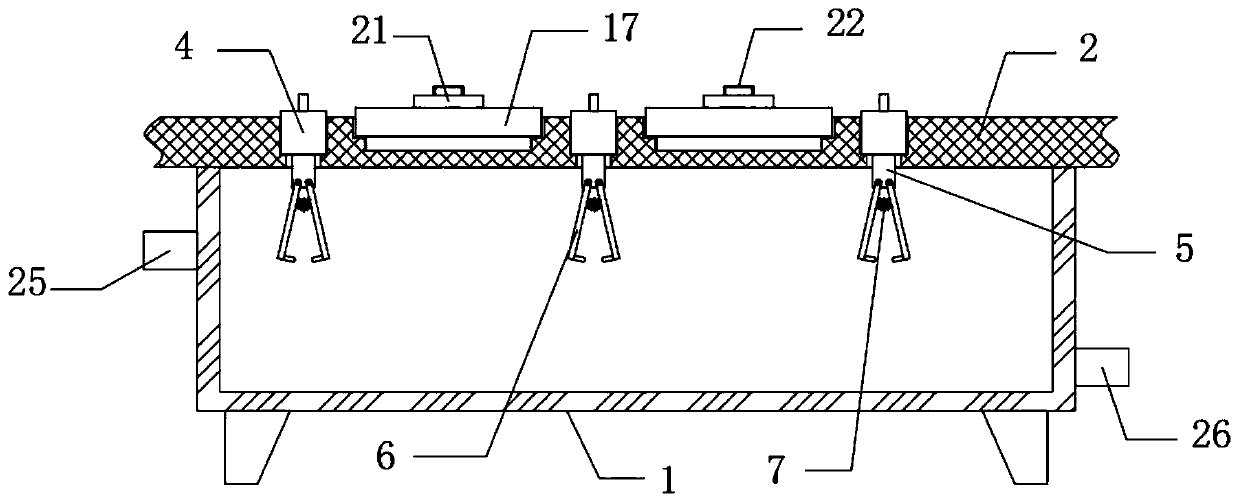

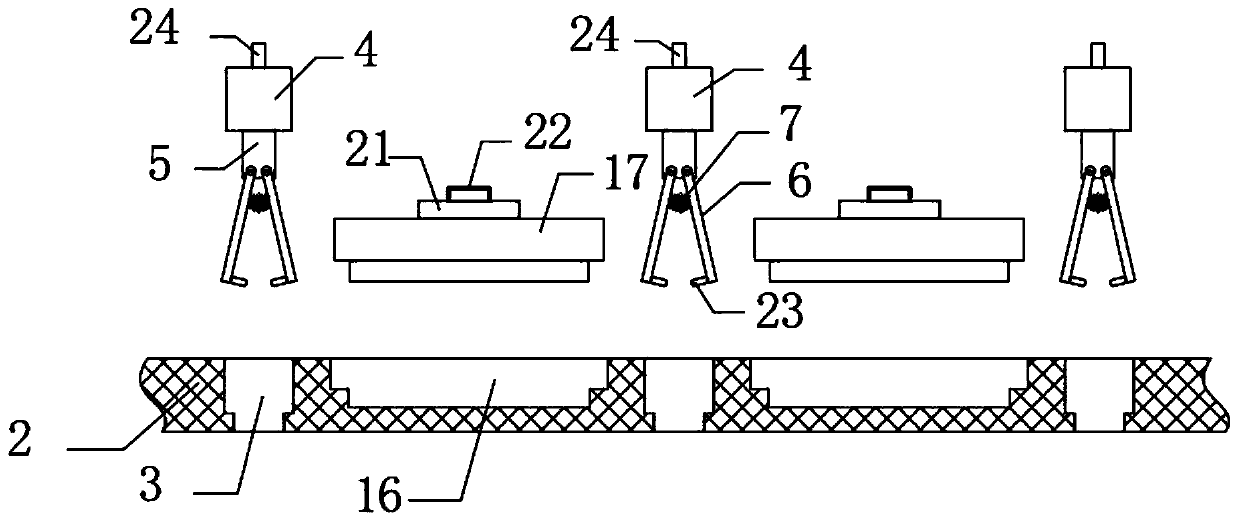

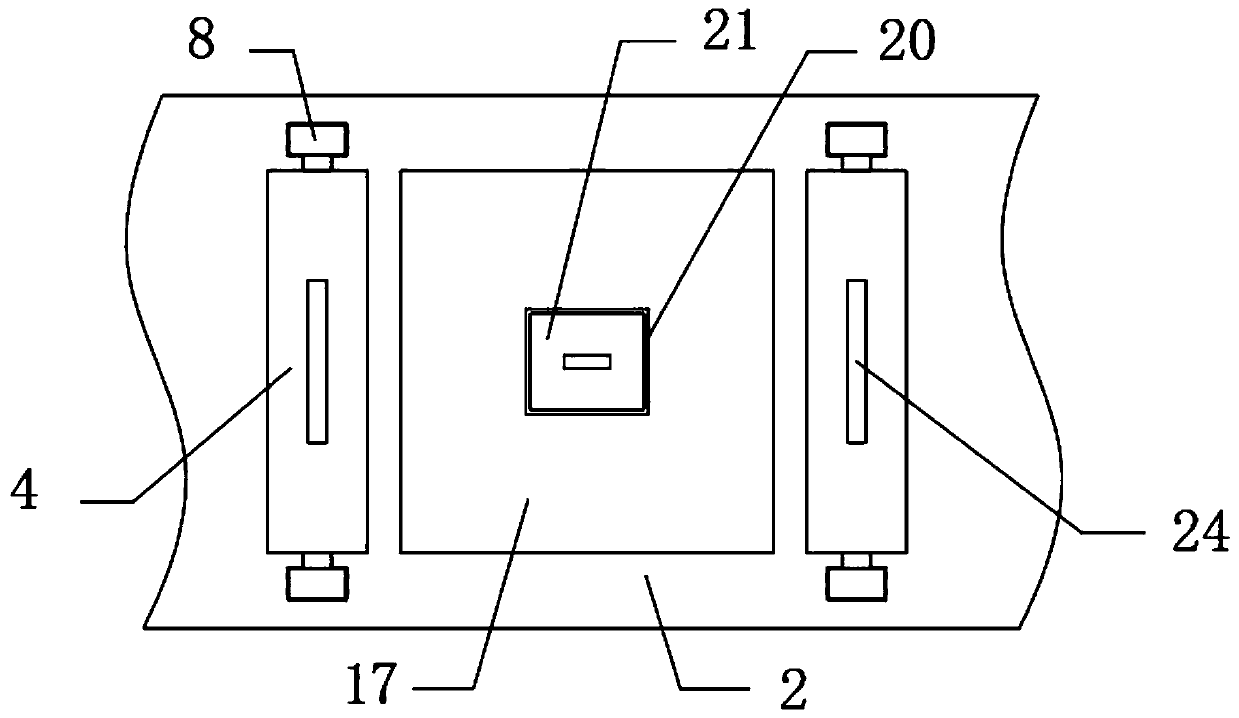

[0045] see Figure 1-6 , a segment dyeing equipment based on monochrome printing and dyeing and its use method, including a dye box 1, please refer to Figure 1-2, the both sides of dye box 1 are communicated with feed pipe 25 and discharge pipe 26 respectively, and on the feed pipe 25 and discharge pipe 26, on-off valve is installed, and feed pipe 25 is convenient to add dyestuff in dye box 1, discharge pipe 26 is convenient to pour out the dye, the switch valve is convenient to control the opening and closing of the feeding pipe 25 and the discharge pipe 26, the top of the dye box 1 is provided with a box cover 2, and the box cover 2 is provided with a plurality of sockets 3, sockets 3 and slots 16 is a ladder structure, the ladder structure can prevent the insert block 4 from falling into the dye box 1, and the insert block 4 is inserted in the socket 3, please refer to Image 6 , the upper end of each plug 4 is fixedly connected with a second handle 24, and the second han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com