Method for increasing utilization rate of carbon resources in phosphate tailings

A technology of high magnesium and phosphorus tailings and utilization rate, applied in the field of waste resource utilization, can solve the problems of low added value of products and low utilization rate of phosphorus tailings resources, so as to increase added value, reduce treatment costs, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

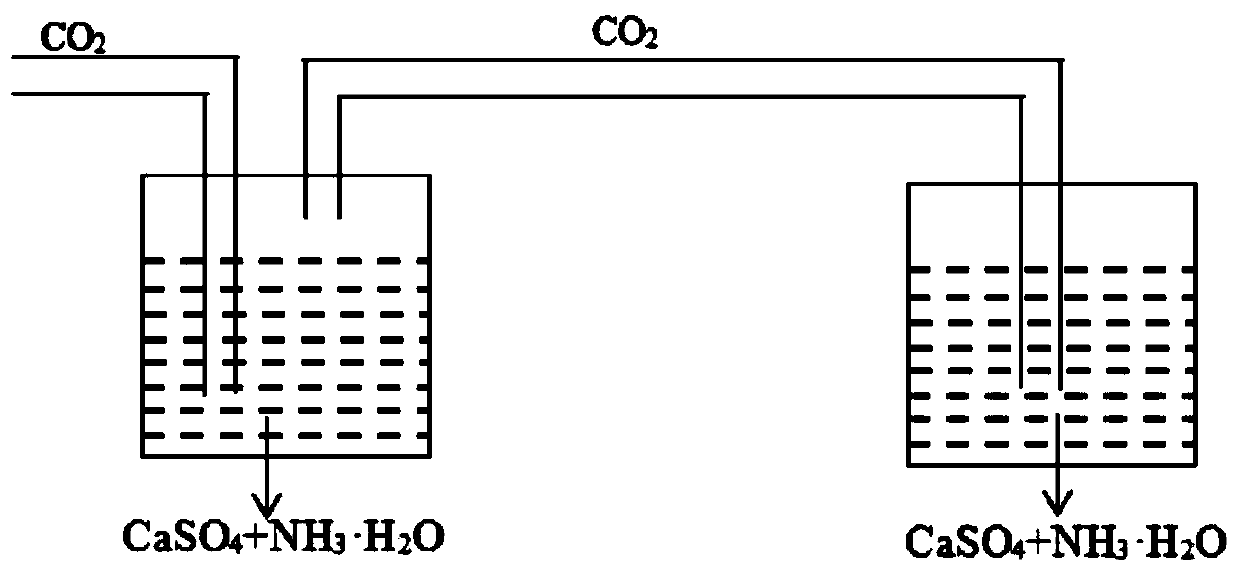

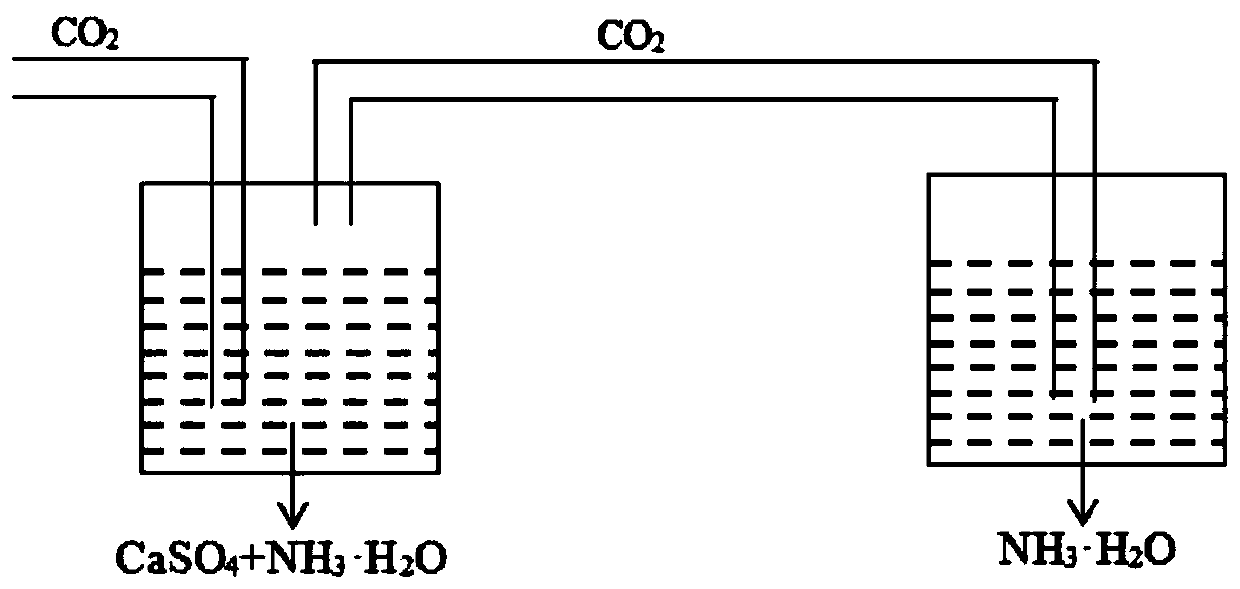

[0032] combine figure 1 As shown, the method for improving the utilization rate of carbon resources in phosphorus tailings of the present embodiment specifically includes the following steps:

[0033] 1) Take 120g of phosphogypsum and place it in a 500ml three-necked flask, slowly add 100g of ammonia water with a mass fraction of 25%, stir and mix thoroughly to obtain a phosphogypsum-ammonia water mixed suspension, and mix the phosphogypsum-ammonia water mixed suspension Divide into two parts, place them in 250ml flasks respectively, and connect them with rubber tubes in the middle;

[0034] 2) Weigh 100g of high-magnesium phosphorus tailings and mix it with 200ml of water, place it in a 3000ml three-necked flask, start stirring, and connect the three-necked flask to one end of the airway, and the other end of the airway is connected to a portion of phosphogypsum- Add 220ml of industrial hydrochloric acid with a mass fraction of 31% (10.35mol / L) slowly to the flask containing...

Embodiment 2

[0037] combine figure 1 As shown, the method for improving the utilization rate of carbon resources in phosphorus tailings of the present embodiment specifically includes the following steps:

[0038] 11) Take 125g of phosphogypsum and place it in a 500ml three-necked flask, slowly add 90g of ammonia water with a mass fraction of 25%, stir and mix thoroughly to obtain a phosphogypsum-ammonia water mixed suspension, and mix the phosphogypsum-ammonia water mixed suspension Divide into two parts, place them in 250ml flasks respectively, and connect them with rubber tubes in the middle;

[0039] 2) Weigh 100g of high-magnesium phosphorus tailings and mix it with 200ml of water, place it in a 3000ml three-necked flask, start stirring, and connect the three-necked flask to one end of the airway, and the other end of the airway is connected to a portion of phosphogypsum- Add 223ml of industrial hydrochloric acid with a mass fraction of 30.8% (10.32mol / L) slowly to the flask containi...

Embodiment 3

[0042] combine figure 1 As shown, the method for improving the utilization rate of carbon resources in phosphorus tailings of the present embodiment specifically includes the following steps:

[0043] 1) Take 120g of phosphogypsum and place it in a 500ml three-necked flask, slowly add 80g of ammonia water with a mass fraction of 25%, fully stir and mix to obtain a phosphogypsum-ammonia water mixed suspension, and mix the phosphogypsum-ammonia water mixed suspension Divide into two parts, place them in 250ml flasks respectively, and connect them with rubber tubes in the middle;

[0044] 2) Weigh 100g of high-magnesium phosphorus tailings and mix it with 200ml of water, place it in a 3000ml three-necked flask, start stirring, and connect the three-necked flask to one end of the airway, and the other end of the airway is connected to a portion of phosphogypsum- Add 240ml of industrial hydrochloric acid with a mass fraction of 30.0% (10.19mol / L) slowly to the flask containing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com