Decorative film, and manufacturing process and application thereof

A decorative film and decorative strip technology, applied in the field of decorative materials, can solve the problems of single visual effect of decorative film, unable to meet the needs of fashion design, etc., to achieve the effect of multi-design space and increase the sense of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

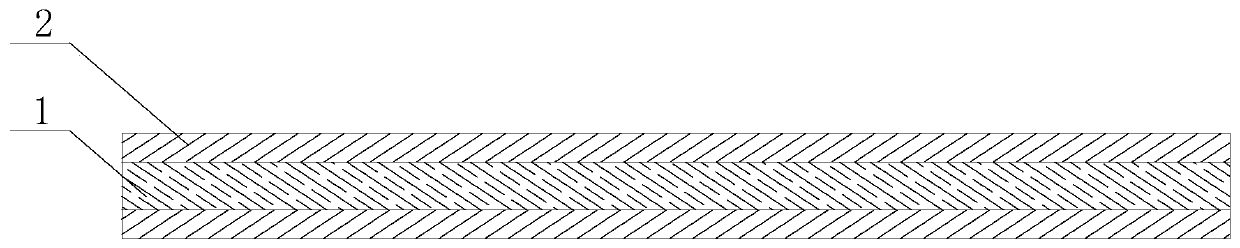

[0044] Such as figure 1 , Figure 3 to Figure 6 The shown decorative film includes a base layer 1, the base layer 1 has fluorescence, the upper surface and the lower surface of the base layer 1 are provided with a one-way film layer 2, and the one-way film layer 2 is provided with a first Pattern 5, the base layer 1 is provided with a second pattern 6; the decorative film is cut to form a decorative strip 4, and one end of the decorative strip 4 is connected to the decorative film.

[0045] Such as Figure 5 As shown, under natural light, the naked eye of the observer can only observe the decorative effect of the first pattern 5 and the decorative strip 4 on the one-way film layer 2, and the decorative film presents a solemn and layered first pattern at this time. 5.

[0046] Such as Figure 6 As shown, when the decorative film is photographed with a flashlight, the instantaneous high exposure causes part of the light to pass through the one-way film layer 2, irradiate the...

Embodiment 2

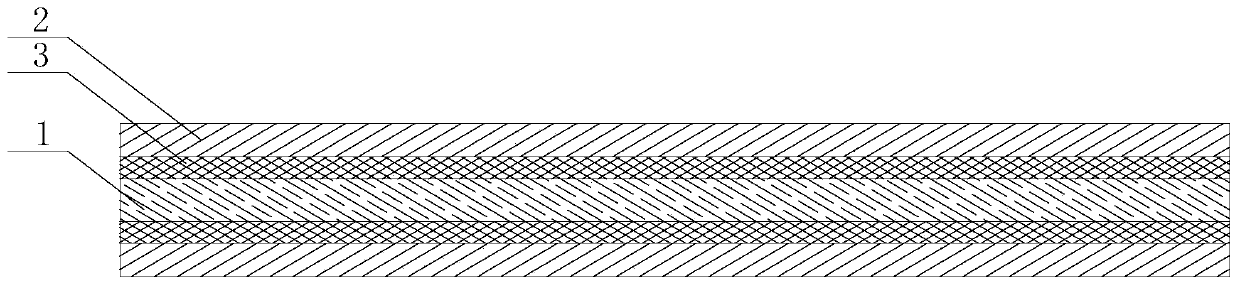

[0053] On the basis of Example 1, such as figure 2 As shown, a toning layer 3 is disposed between the base layer 1 and the one-way film layer 2, and the toning layer 3 is at least partially light-transmissive.

[0054] The toning layer 3 is used to adjust the color and color difference of the second pattern, so as to change the overall visual effect presented by the second pattern. The toning layer 3 can be partly translucent and partly opaque, and cooperate with the second pattern itself to produce a pattern with alternate light and dark and a more layered sense, further increasing the design space of the decorative film.

[0055] In some embodiments, the toning layer 3 may include multiple layers to produce richer color matching.

Embodiment 3

[0057] The preparation method of the decorative film in the above-mentioned embodiment comprises the following steps:

[0058] Cutting and cleaning the base layer 1 and the one-way film layer 2 for standby;

[0059] Attaching a one-way film layer 2 on the upper surface and / or the lower surface of the base layer 1 to form a decorative film;

[0060] Cutting the decorative film to form a decorative strip 4, one end of the decorative strip 4 is a fixed end connected to the decorative film, and the other end is a movable end capable of turning around the decorative film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com