Method for improving electrolyte infiltration of ternary battery and obtained battery

A ternary battery and electrolyte technology, applied in the field of lithium ion batteries, can solve the problems of affecting the formation of SEI film and uneven distribution of electrolyte, and achieve the effect of shortening the soaking time, shortening the soaking time, and shortening the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

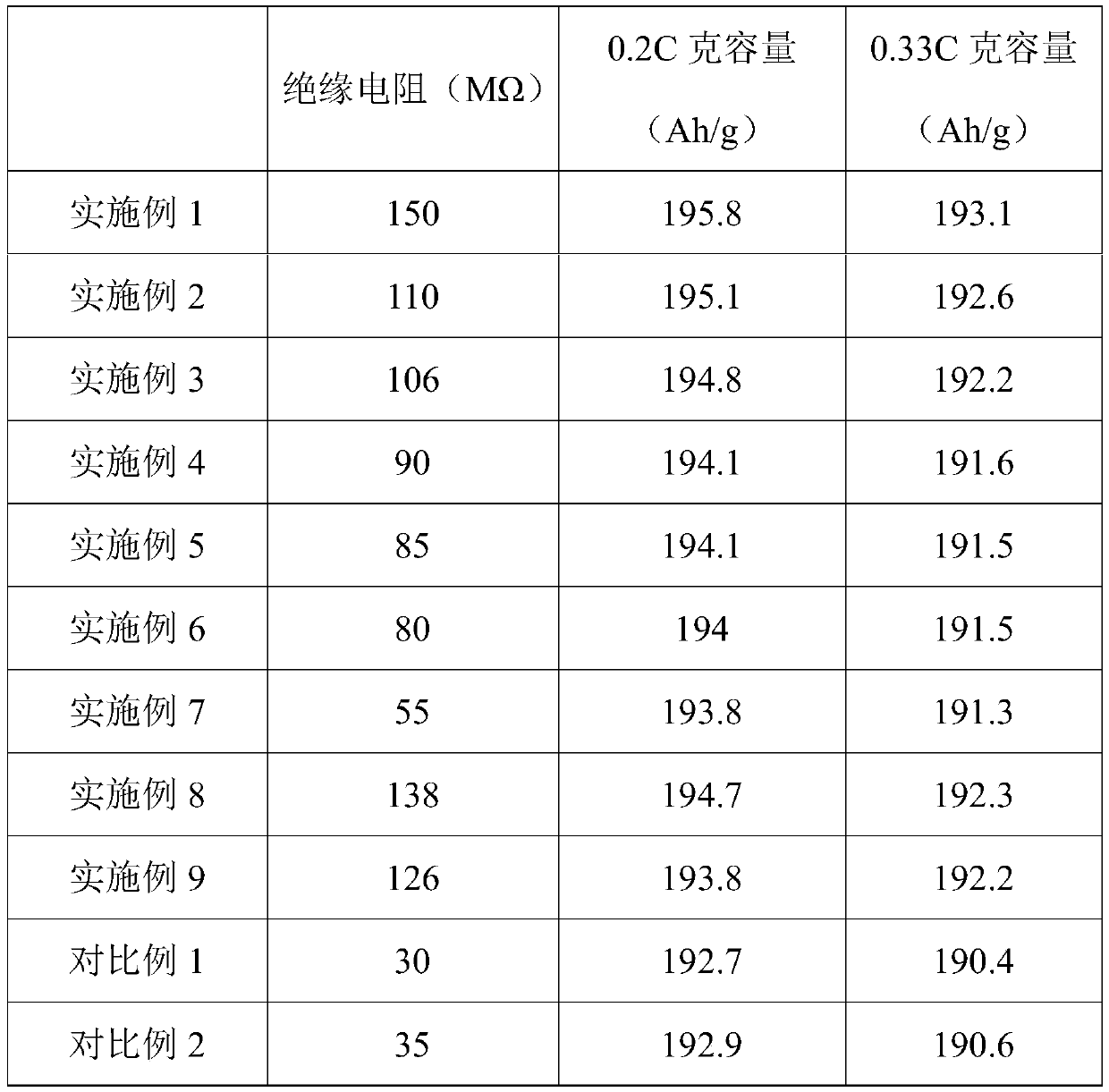

Embodiment 1

[0038] After liquid injection, the high-nickel ternary soft-pack batteries were vibrated at a frequency of 25Hz for 8 minutes in turn. After the batteries were packaged, the insulation resistance was tested to screen out defective products, and they were left to stand for 60 minutes in an environment with a vacuum degree of -80KPa.

Embodiment 2

[0040] After liquid injection, the high-nickel ternary soft-pack battery was vibrated at a frequency of 10Hz for 8 minutes in sequence. After the battery was packaged, the insulation resistance was tested to screen out defective products, and it was left to stand for 60 minutes in an environment with a vacuum degree of -80KPa.

Embodiment 3

[0042] After liquid injection, the high-nickel ternary soft-pack batteries were vibrated at a frequency of 50Hz for 8 minutes in sequence. After the batteries were packaged, the insulation resistance was tested to screen out defective products, and they were left to stand for 60 minutes in an environment with a vacuum degree of -80KPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com