Die for preventing chip from falling

A chip and mold technology, applied in the field of molds to prevent chips from falling, can solve problems such as poor production, undetectable defects, chip leakage, etc., to reduce the frequency of personnel inspections, reduce the probability of quality risks, and improve product quality. reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The utility model will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

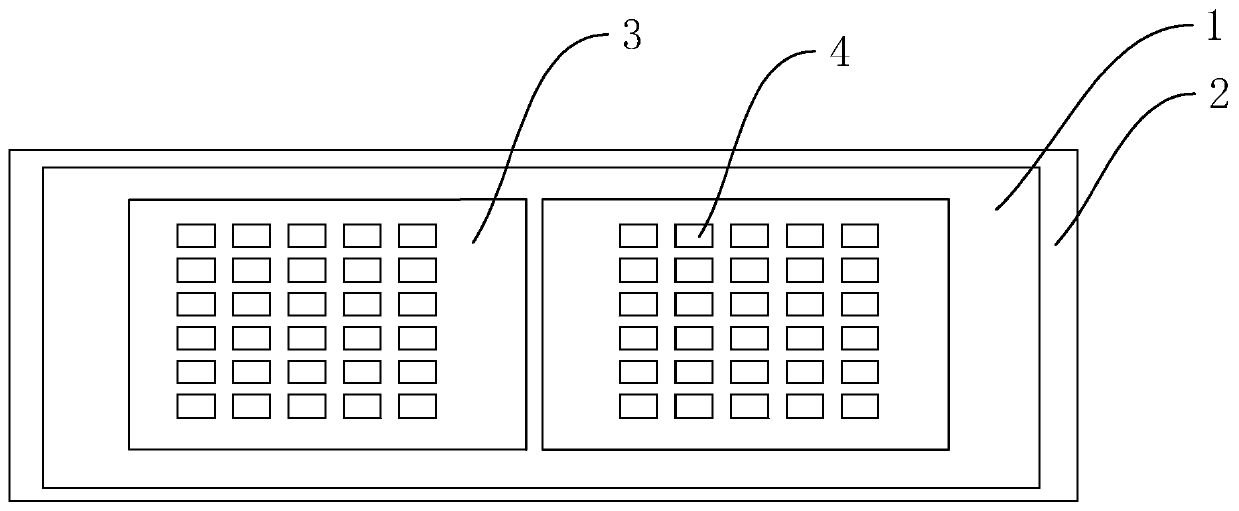

[0019] The invention provides a mold for preventing chips from falling, which includes an upper fixture 1, a lower fixture 2, a substrate 3, and a chip 4;

[0020] The chip 4 is disposed on the substrate 3 ; the upper fixture 1 cooperates with the lower fixture 2 to fix the chip 4 on the substrate 3 .

[0021] Preferably in this embodiment, the upper fixture 1 is also symmetrically provided with two square through holes.

[0022] Preferably in this embodiment, a protrusion extends downwards from both ends of the upper fixture 1 ; the protrusion and the lower frame 2 form a space for the chip 4 to be clamped.

[0023] Preferably in this embodiment, the upper fixture 1 further includes a middle beam; the middle beam is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com