Vermicular graphite cast iron vermicular effect multi-feature-point thermal analysis evaluation method

An evaluation method and technology of vermicular graphite cast iron, applied in the field of metallurgy and casting, can solve the problems of difficult to control and monitor the O content accurately, and achieve good evaluation effect and rapid evaluation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of multi-feature point thermal analysis evaluation method of vermicular effect of vermicular graphite cast iron, described evaluation method comprises the following steps:

[0024] Step 1: Extract multiple feature points on the thermal analysis cooling curve of the creeping inoculated molten iron sample under production conditions;

[0025] Step 2: Set up a multi-characteristic point combination vector representation model of the ideal molten iron creeping metallurgical state;

[0026] Step 3: Comparing the multiple feature points under the production conditions of step 1 with the combination vector of multiple feature points in the ideal state of step 2;

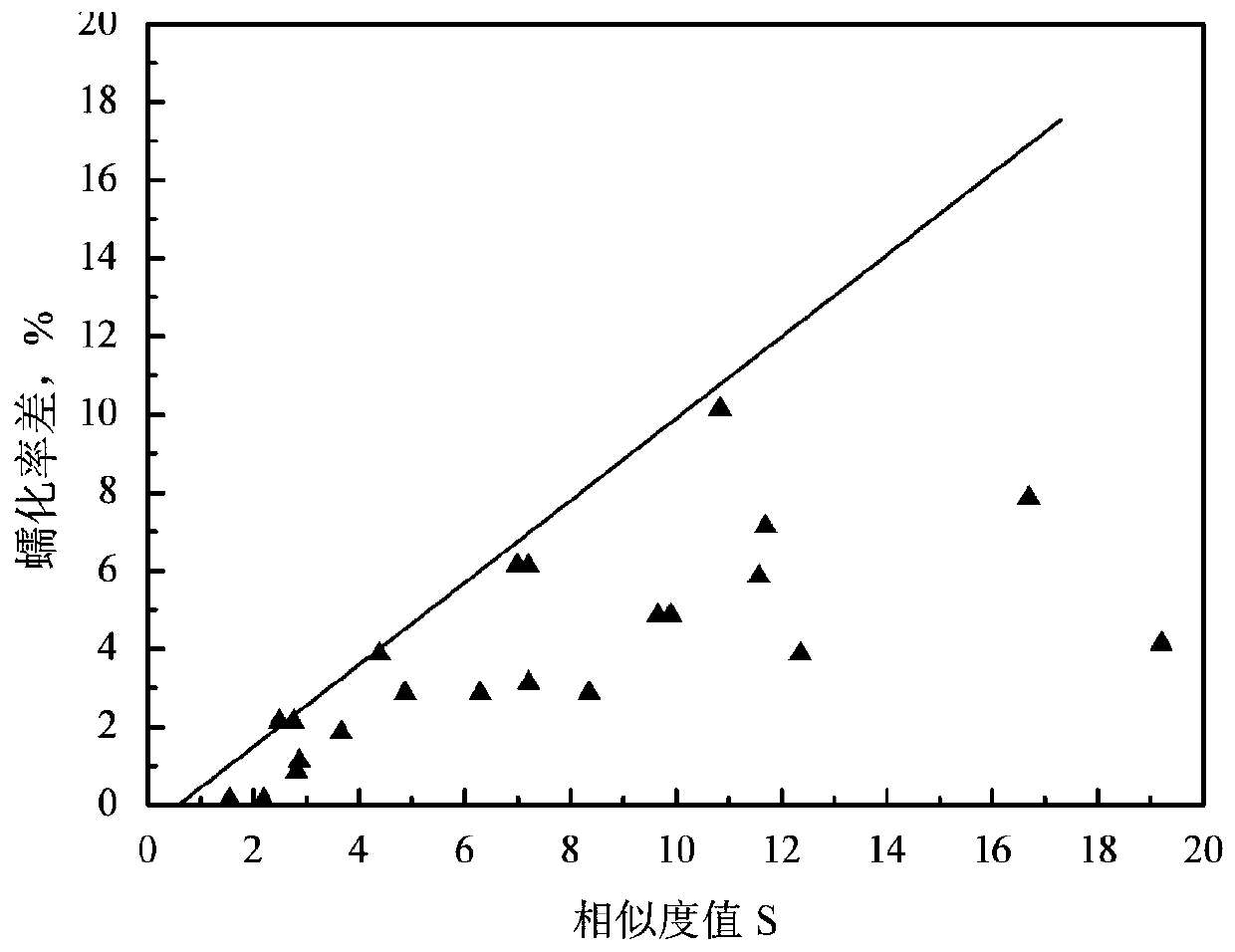

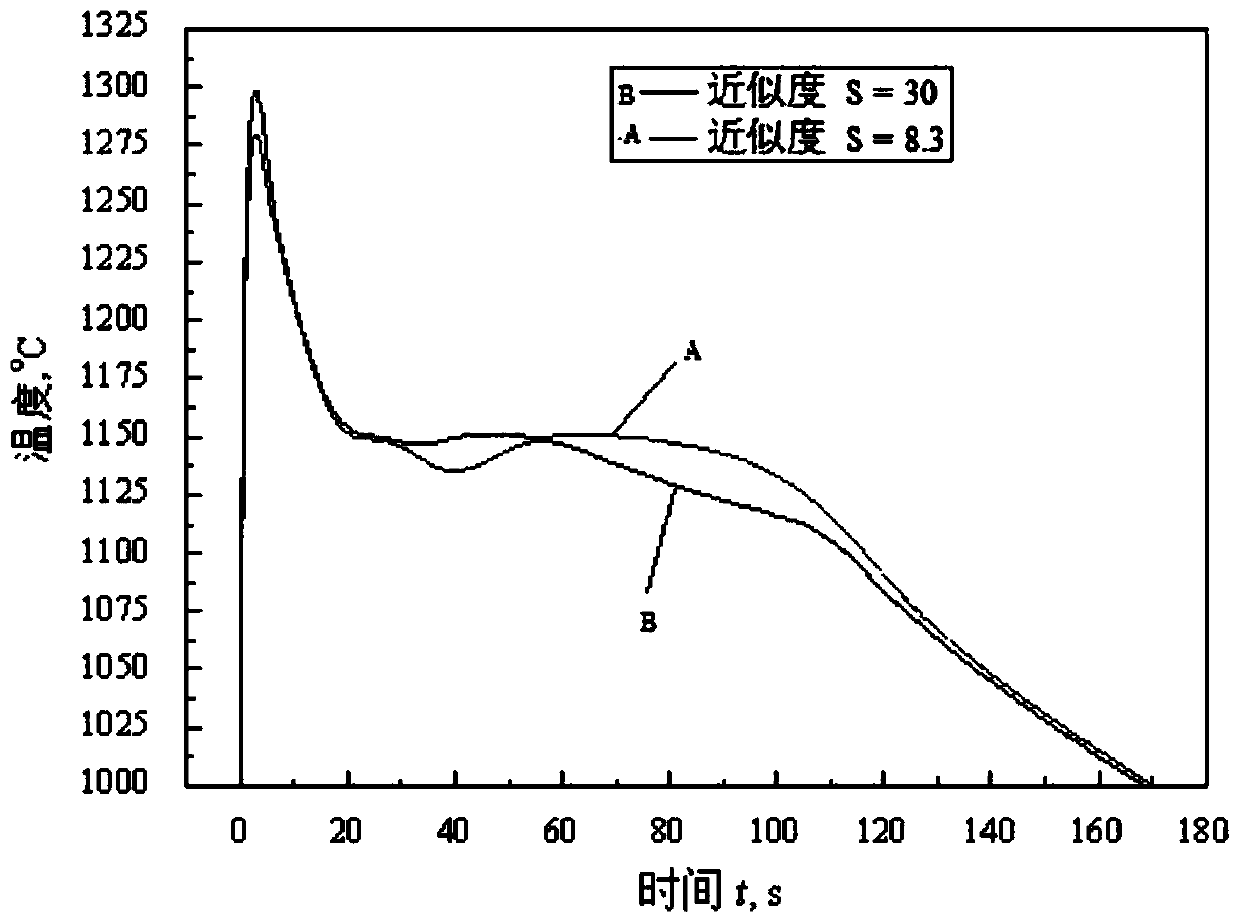

[0027] Step 4: Determine the comparison approximation coefficient S through the comparison in step 3, which is used to predict the actual creeping effect of molten iron.

[0028] Further, the step 2 is specifically that the characterization model is:

[0029] [T Max ,T L ,T N , (dT / dt) N ,T ...

Embodiment 2

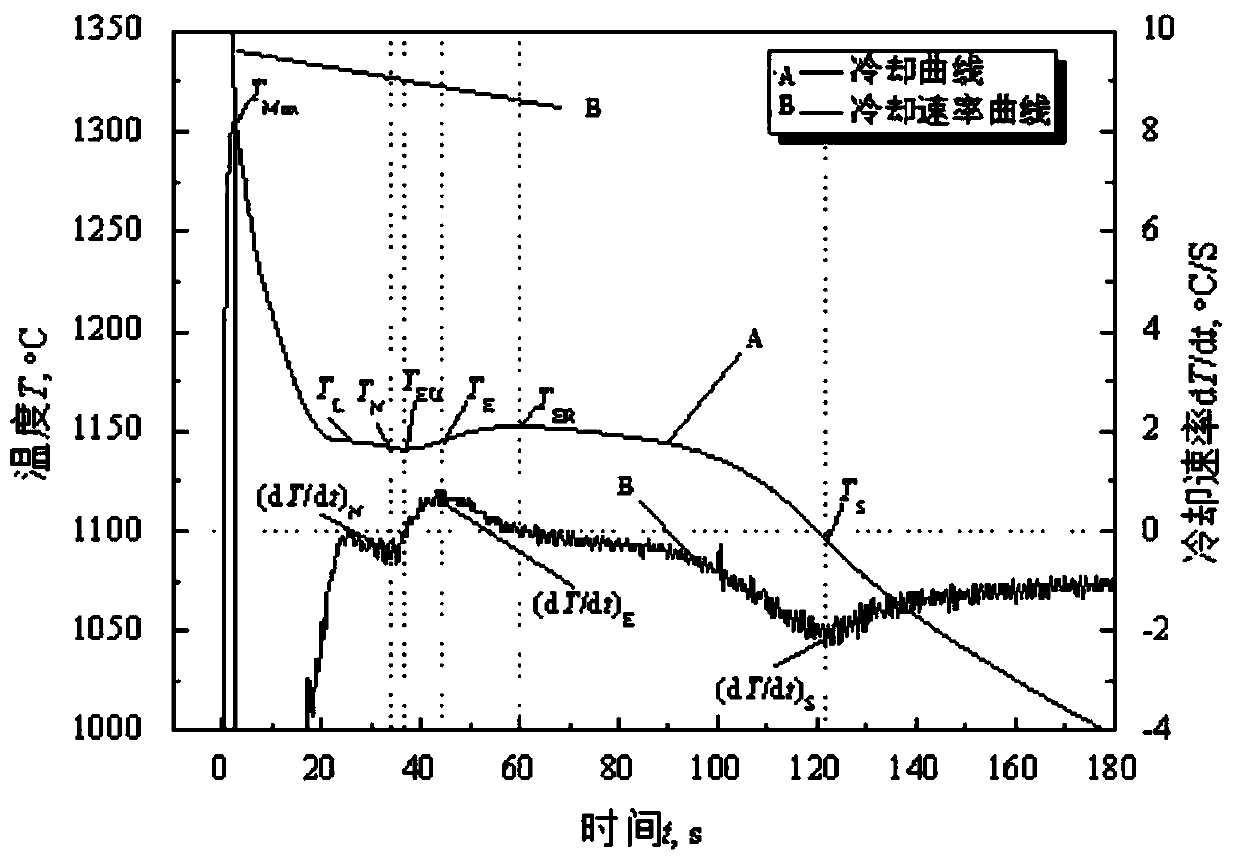

[0035] Establishment of characteristic point vector model for thermal analysis of ideal molten iron creeping metallurgical state characterization. Under the actual production conditions of a vermicular graphite cast iron foundry, samples of thermal analysis cooling curves of vermicular molten iron were collected. The composition control range of the vermicular molten iron was C: 3.7-3.8; Si: 2.0-2.4; Mn: 0.3-0.5; P:≤0.05; S:0.01~0.02; Cu:0.3~0.6; Sn:0.02~0.04; Mg:0.01~0.02; RE:0.01~0.02. Use a resin sand sample cup with an inner cavity size of Φ30×50mm and a wall thickness of 5mm for thermal analysis, and extract the maximum test temperature T on the cooling curve Max , liquidus temperature T L , eutectic nucleation temperature T N , Cooling rate of eutectic nucleation point (dT / dt) N , the lowest eutectic temperature T EU , Maximum eutectic recovery rate temperature T E , maximum eutectic recovery rate (dT / dt) E , the highest eutectic recovery temperature T ER , Solidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com