Test device for measuring axial multi-point slip amount of concrete-filled steel tube

A technology for concrete-filled steel tubes and test devices, which is applied in the field of civil engineering research, can solve the problems of not being able to reflect the sliding performance of concrete-filled steel tubes in detail, the difference in sliding deformation between the free end and the loading end, and the small gap between the steel tube and the core concrete, etc., to achieve Promote the effect of high application value, low manufacturing and processing difficulty, and fast testing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

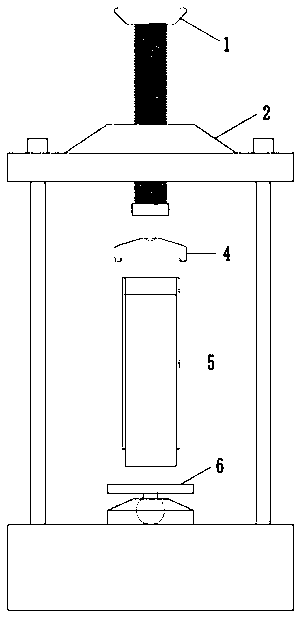

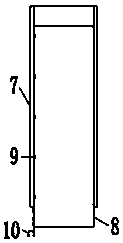

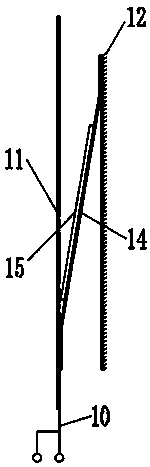

[0023] Such as Figure 1-4 As shown, the present invention provides a test device for measuring the axial multi-point slippage of concrete filled steel tubes, comprising a pressurized bolt 1, a workbench 2, an upper clamping groove 4, a concrete filled steel tube specimen 5 and a bottom platform 6; The cloud platform 6 is placed on the platform of the workbench 2, and the steel pipe concrete specimen 5 is placed between the upper slot 4 and the bottom platform 6, and an external load controlled by force or deformation is applied through the pressure bolt 1, so that The force or load applied to the concrete-filled steel pipe specimen 5 reaches a uniform force, and the push-out test load of the concrete-filled steel pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com