High-temperature solid ceramsite sand electric heating experiment device for supercritical carbon dioxide power generation

A technology for high-temperature solids and experimental devices, applied in the direction of electric heating devices, measuring devices, heating element shapes, etc., can solve problems such as local ablation, large heat loss, and long residence time of particles, so as to reduce system operating current and system loss, Strong anti-system short-circuit impact capability and the effect of improving technical and economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

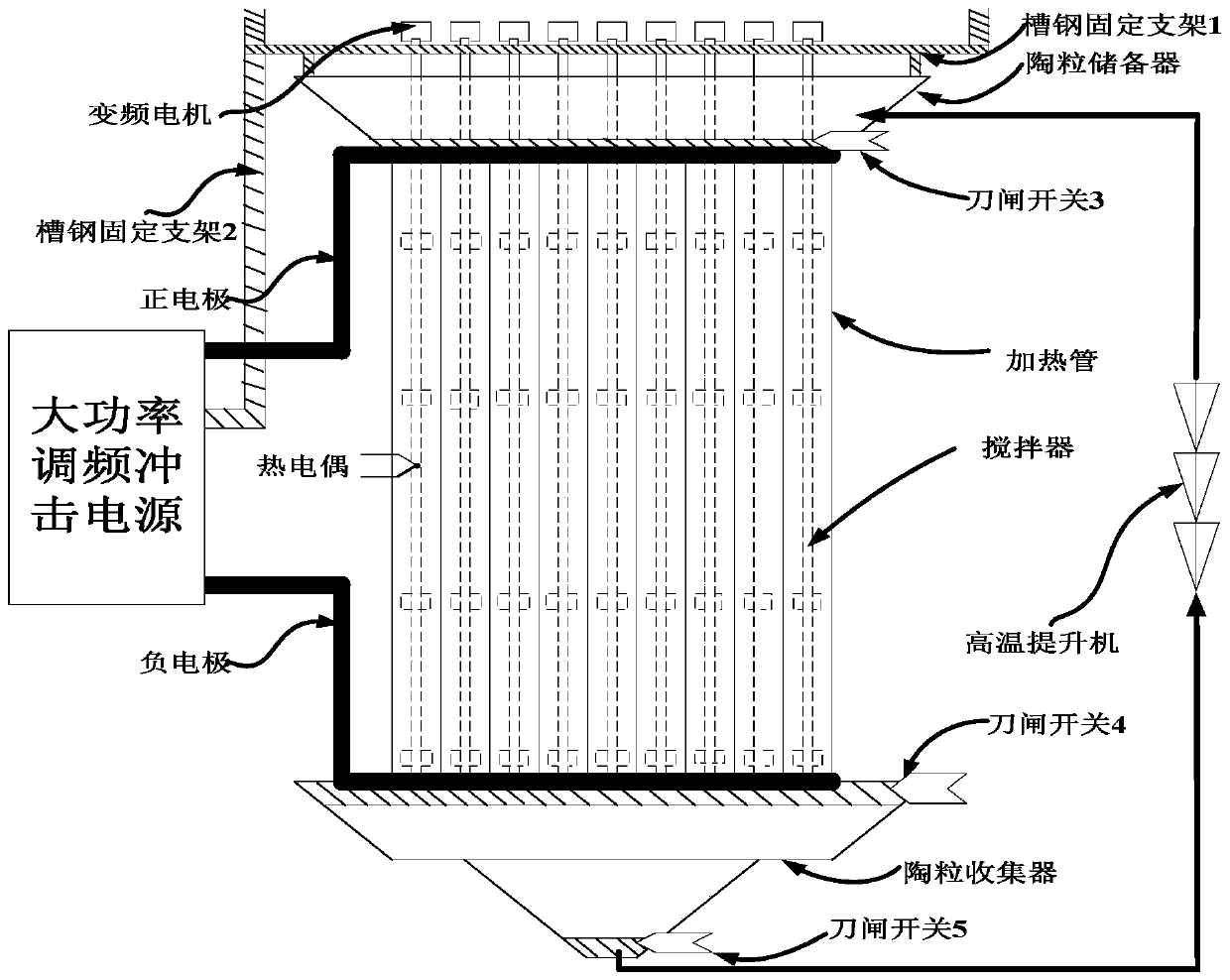

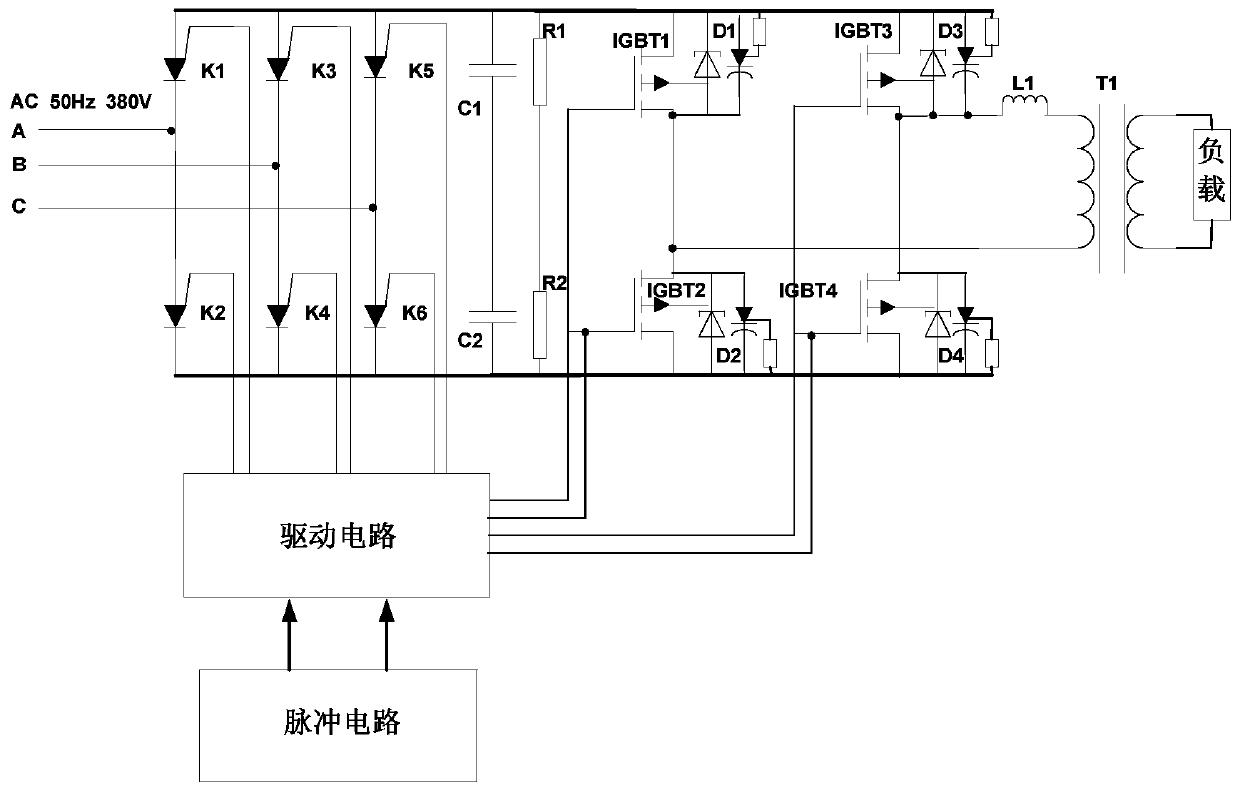

[0033] The invention consists of two parts: a high-power frequency-modulated impact power supply and a high-temperature solid ceramsite sand electric heating experimental device. The high-power frequency-modulated impact power supply supplies power for the high-temperature solid ceramsite sand electric heating experimental device.

[0034] The high-temperature solid ceramsite sand electric heating experiment device comprises a first channel steel fixed bracket 1 and a second channel steel fixed bracket 2, and the second channel steel fixed bracket 2 is fixed below the first channel steel fixed bracket 1 by welding, Frequency conversion motor, ceramsite reserver, 3 knife switches, a pair of electrodes, stirrer, heating tube, ceramsite collector, and thermocouple. The high-power frequency-modulated impact power supply is fixed on the second chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com