Superconducting wire performance measuring device based on conduction cooling

A measurement device, conduction cooling technology, applied in the direction of the measurement device, measurement device casing, measurement electronics, etc., can solve the problems of sample temperature fluctuation, complex equipment, a lot of preparation work, etc., and achieve the effect of wide length range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

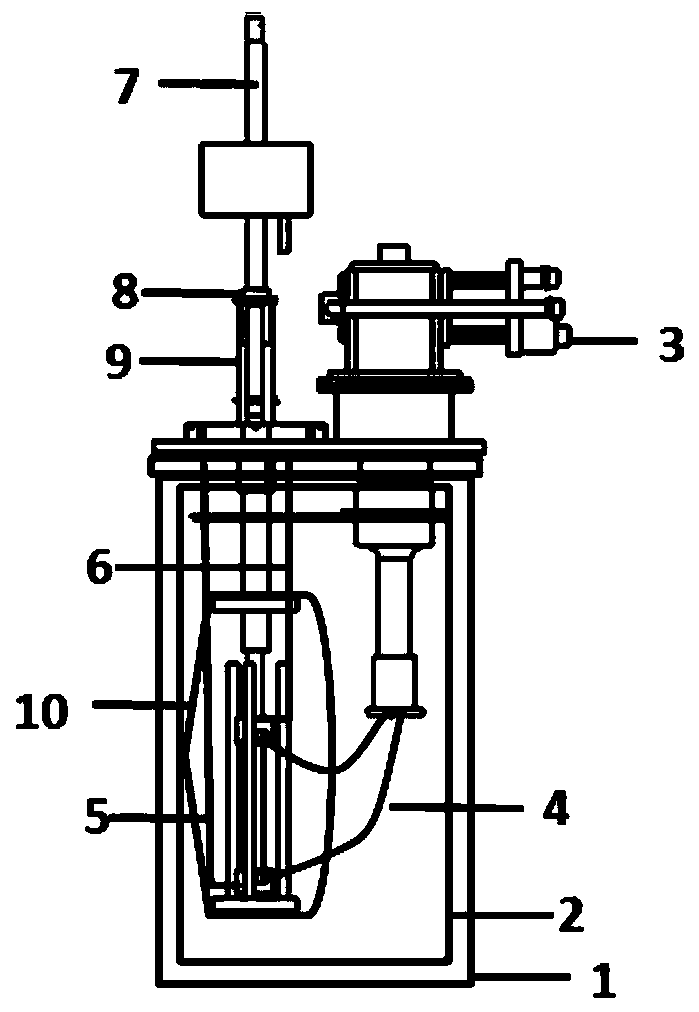

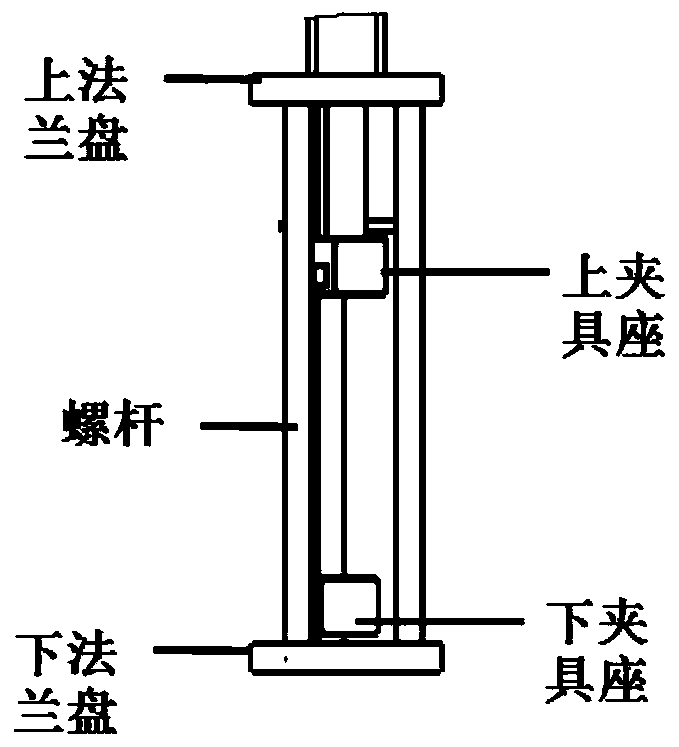

[0027] like figure 1 As shown, the performance measurement device of the conduction cooled superconducting wire of the present invention includes a vacuum dewar 1 , a temperature control assembly, an electrical assembly, a supporting device, a fixture and a loading rod 7 .

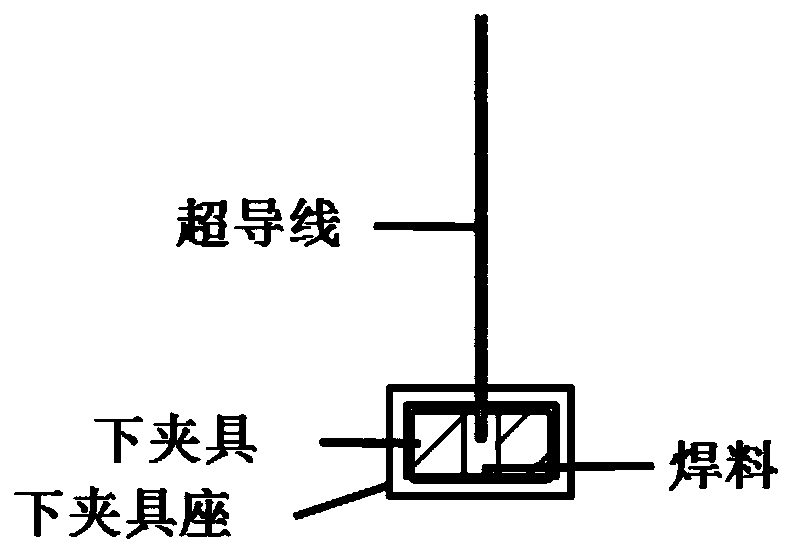

[0028] Temperature control components, electrical components, supporting devices and fixtures are placed inside the vacuum dewar 1 , and the loading rod 7 is arranged on the central axis outside the vacuum dewar 1 . The superconducting wire is supported by a fixture and arranged in the vacuum dewar 1 . A radiation shield 2 is installed inside the vacuum dewar 1 .

[0029] The temperature control component is cooled by the refrigerator 3 installed outside the vacuum dewar 1, and the cold energy is conducted to the clamps at both ends of the superconducting wire through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com