Three-dimensional steam cavity type phase change heat storage device

A phase-change heat storage and steam cavity technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc. problems, to achieve the effect of improving heat transfer efficiency, eliminating contact thermal resistance, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

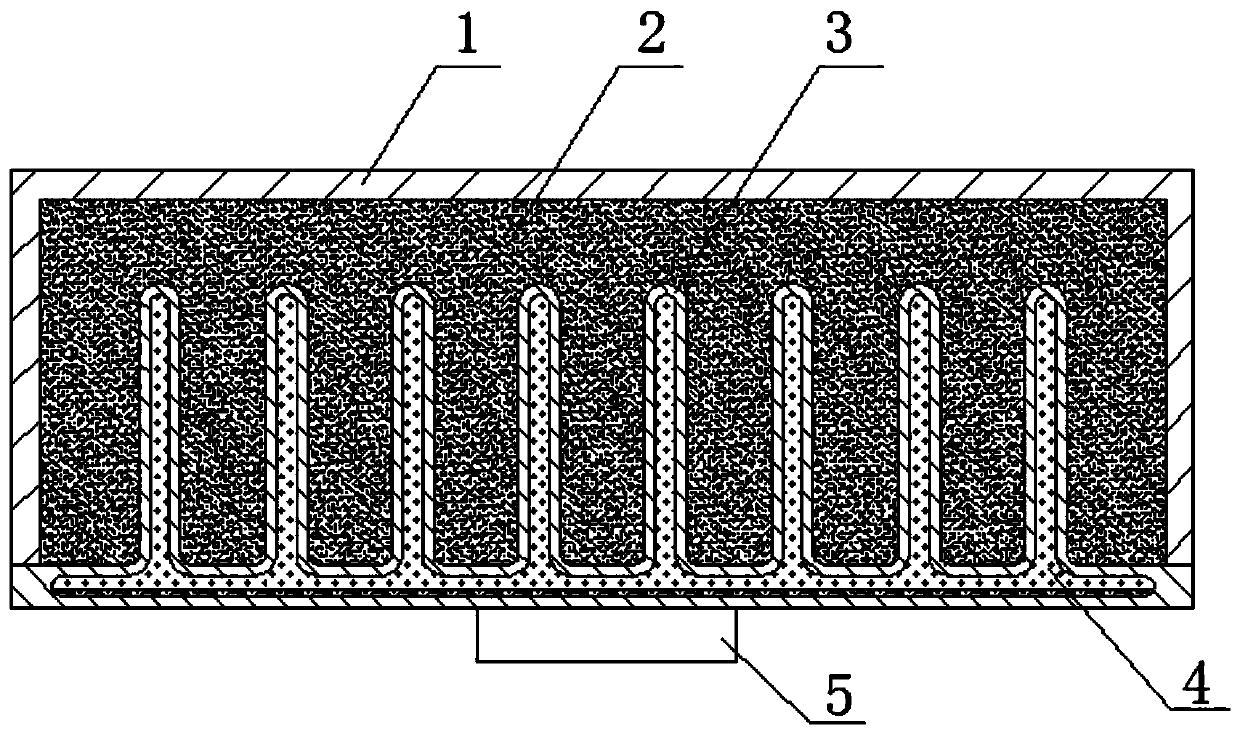

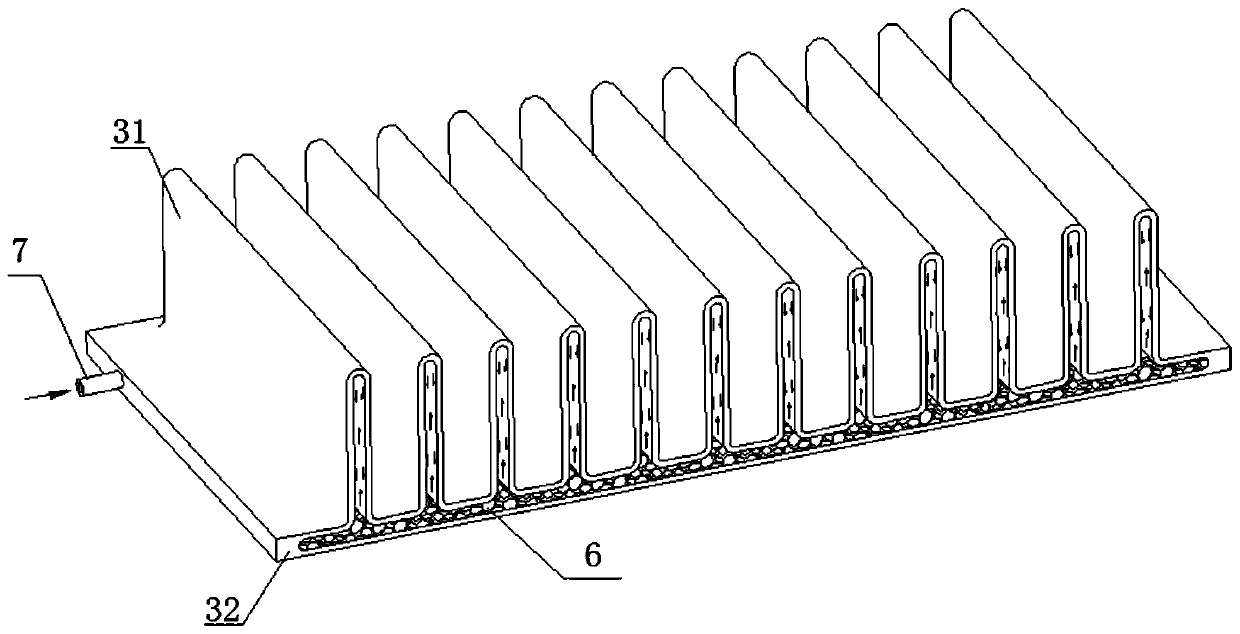

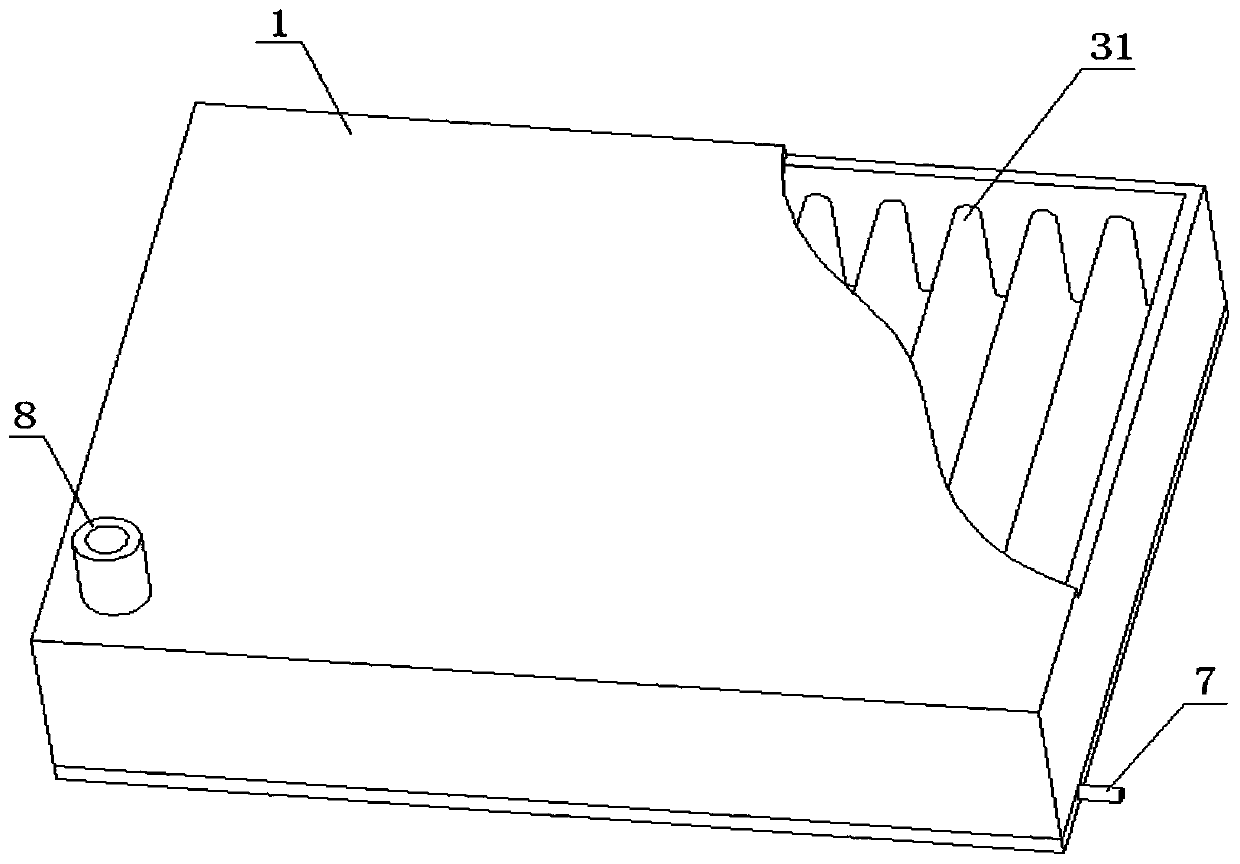

[0025] Please combine Figure 1 to Figure 3 As shown, the present invention provides a three-dimensional steam cavity type phase change heat storage device, which includes a three-dimensional steam cavity 3 and an encapsulation shell 1 covering the three-dimensional steam cavity 3 . The three-dimensional steam cavity 3 includes a heat transfer base plate 32 and a plurality of cooling teeth 31 extending upward from the heat transfer base plate 32 . Both the heat transfer substrate 32 and the heat dissipation teeth 31 are hollow inside. And the internal cavity of the heat transfer substrate is connected with the internal cavity of each cooling tooth, which is called the overall airtight cavity; the three-dimensional steam cavity 3 is connected with the package shell 1 by screwing or welding. A sealed cavity is formed between the packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com