Boiler flue gas waste heat recycling system based on heat exchanging absorption tower and method

A waste heat recovery system and boiler flue gas technology, applied in the field of flue gas waste heat recovery, can solve the problems of low energy utilization rate of boiler system, reduced load of denitrification device, high equipment investment cost, etc., to prevent dust accumulation and save desulfurization device , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

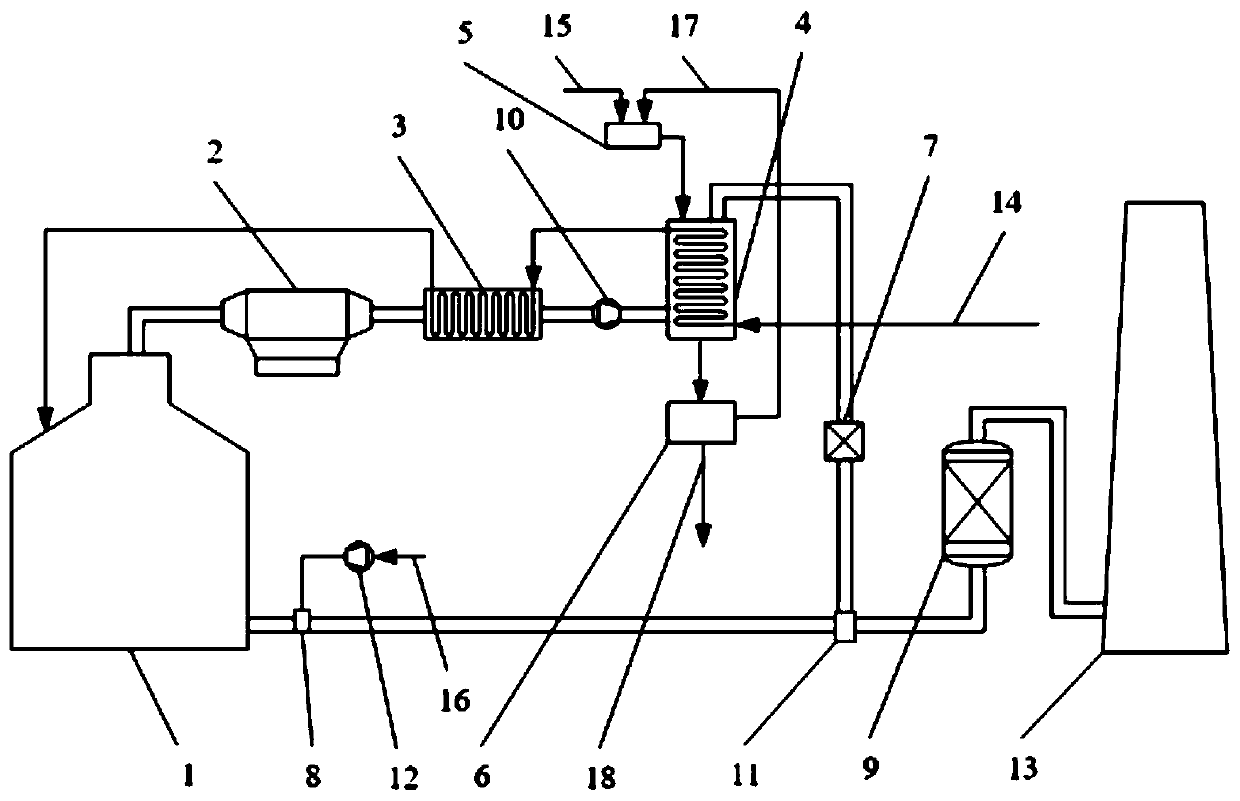

[0030] Such as figure 1As shown, a boiler flue gas waste heat recovery system based on heat exchange and absorption tower, including boiler 1, electrostatic precipitator 2, economizer 3, booster fan 10, heat exchange and absorption tower 4, ammonia solution feeding device 5, crystallization Device 6, water eliminator 7, air mixer 8, induced draft fan 12, splitter 11, denitrification device 9 and chimney 13; heat exchange coil is arranged inside heat exchange absorption tower 4; There are smoke inlet and water inlet, the bottom of the tower kettle is equipped with a material outlet, and the top of the tower is respectively equipped with a smoke outlet and a material inlet; the smoke outlet of the boiler 1 is connected to the smoke inlet of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com