Plasma cleaning device of coated substrate, and use method of plasma cleaning device

A plasma cleaning and substrate technology, applied in the direction of ion implantation plating, sputtering plating, gaseous chemical plating, etc., can solve the problems of uneven coverage, low ionization rate of cleaning medium, affecting the quality of coating, etc., to avoid Overheating damage, good cleaning effect, high application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

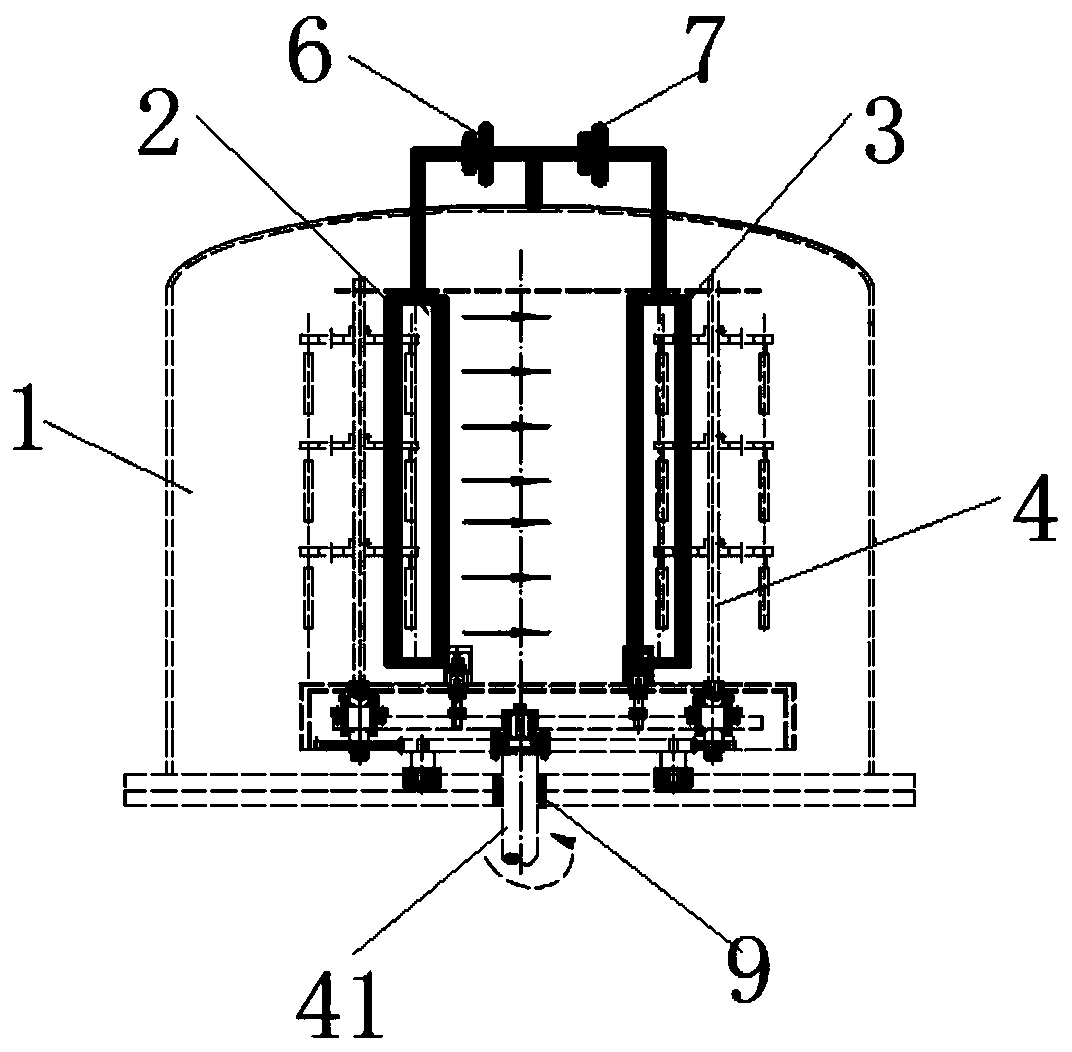

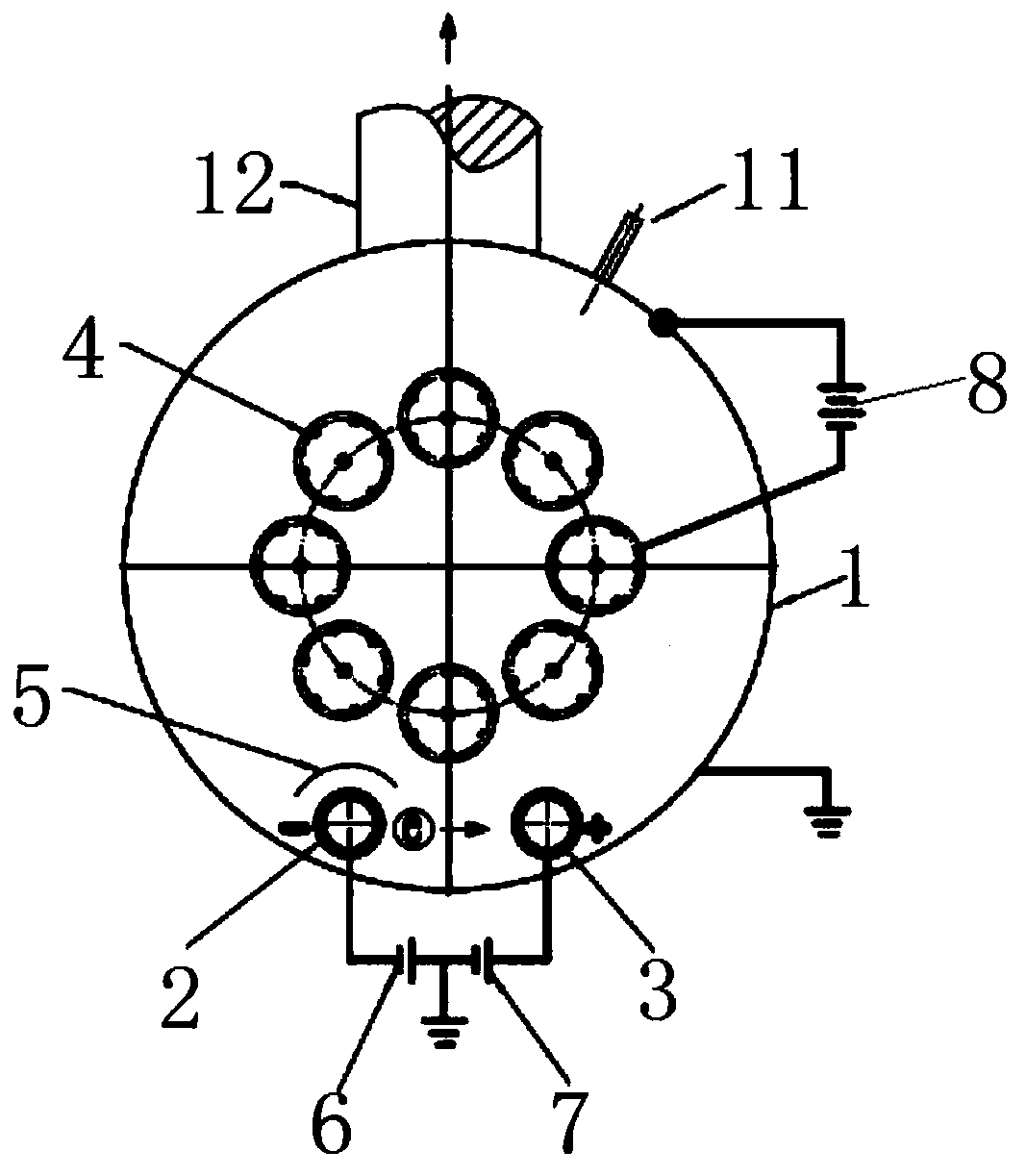

[0035] As attached Figure 1-2 As shown, a plasma cleaning device for coated substrates includes a vacuum chamber 1, which has a gas-filling hole 11 and a suction hole 12, and also includes an ionizing cathode 2, an ionizing anode 3, a workpiece holder 4, and a workpiece holder 4 located in the vacuum chamber 1. Baffle 5 and ionization source one 6, ionization source two 7, and power source 8 located outside the vacuum chamber;

[0036] The anode grounded cathode of the ionization source 6 is connected to the ionization cathode 2, the cathode grounded of the ionization source 2 7 is connected to the ionization anode 3, the anode grounded cathode of the power supply 8 is connected to the workpiece holder 4, and the baffle 5 is located between the ionization cathode 2 and the workpiece holder 4. And the height is equal to the vacuum chamber 1;

[0037] The workpiece holder 4 is rotationally sealed and connected with the bottom end of the vacuum chamber 1.

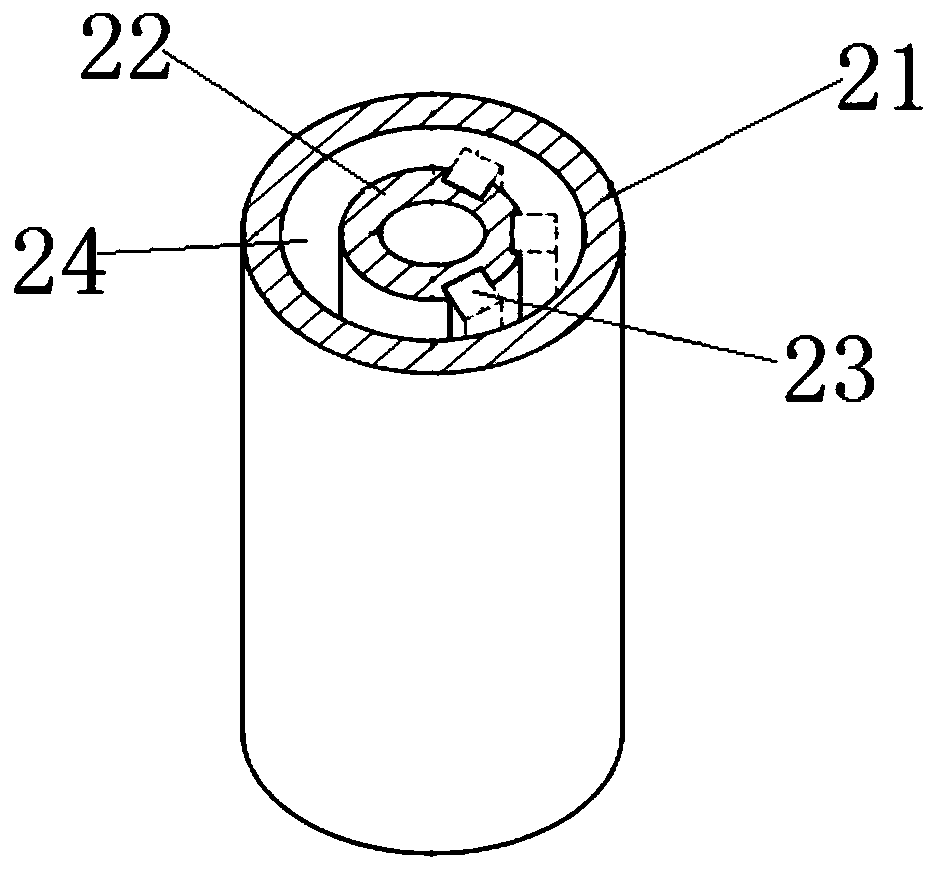

[0038] As attached Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com