Method for preparing PHA by fermenting high-salt molasses serving as raw material

A molasses and high-salt technology, applied in the field of fermentation and preparation of PHA, can solve problems such as being difficult to meet the needs of environmental protection, and achieve the effects of reducing additional operation and economic costs, reducing production costs, and reducing the addition of salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

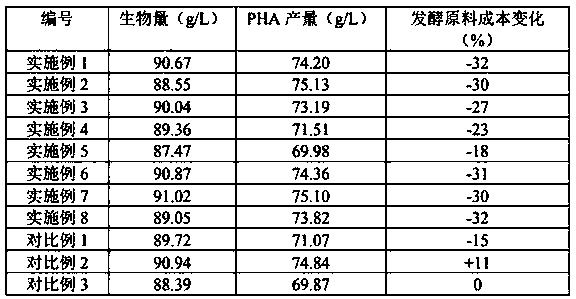

Examples

Embodiment approach

[0027] According to a preferred embodiment of the present invention, the high-salt molasses is high-salt cane molasses, based on dry weight, its salt content is more than 9% by weight, for example, 9-11% by weight, and the sugar content is 50% by weight Above, for example, 50-70% by weight, the sugar includes glucose, sucrose and fructose, wherein, in terms of total sugar, the content of glucose is 5-15% by weight, the content of sucrose is 75-85% by weight, and the content of fructose It is 5-12 weight percent.

[0028] According to the present invention, the high-salt molasses may be crude high-salt molasses, refined high-salt molasses, or syrup obtained after decolorization and dilution of refined high-salt molasses.

[0029] According to the present invention, the content of the high-salt molasses in the fermentation medium can be selected within a wide range, and it can completely or partially replace the carbon source (glucose) in the fermentation medium. According to a...

preparation example

[0090] This preparation example is used to illustrate the activation of fermentation strains

[0091] Seed medium: containing 8g / L yeast powder, 12g / L peptone and 55g / L sodium chloride.

[0092] Halomonas was inoculated in the seed medium for primary activation culture at 37°C and 200rpm, and cultivated to OD 600 Reach about 4, obtain first-grade seed liquid;

[0093] Inoculate the primary seed liquid into the seed medium with an inoculation amount of 10% by volume, carry out secondary activation culture at 37°C and 200rpm, and cultivate to OD 600 Reach about 4, obtain secondary seed liquid, obtain fermented seed liquid.

Embodiment 1

[0095] This embodiment is used to illustrate the method for preparing PHA by fermentation provided by the present invention

[0096] Fermentation medium: Relative to 1L of fermentation medium, the content of high-salt molasses 1 is 25mL, the content of yeast powder is 17g, the content of dipotassium hydrogen phosphate is 3.5g, the content of disodium hydrogen phosphate is 6.2g, and the content of magnesium sulfate The content is 0.25g, and the content of sodium chloride is 55g. Adjust the pH to 8.5.

[0097] Supplement 1: High-salt molasses 1 is used as the carbon source, yeast powder is used as the nitrogen source; the carbon-to-nitrogen ratio is 16:1. Among them, relative to 1L of the first nutrient substance, 1 640 mL of high-salt molasses, 108 g of yeast powder; the volume ratio of supplement 1 to fermentation medium was 9:100.

[0098] Supplement 2: High-salt molasses 1 is used as carbon source, yeast powder is used as nitrogen source; the ratio of carbon to nitrogen is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com