Quick-molding self-healing hydrogel and preparation method thereof

A hydrogel and self-healing technology, applied in the field of rapid prototyping self-healing hydrogel and its preparation, can solve the limitations of hydrogel mechanical strength and self-healing ability, hydrogel toxicity, and self-healing efficiency Advanced problems, to achieve the effect of improving self-healing performance, improving mechanical properties, and overcoming irreversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of rapidly forming self-healing hydrogel, comprising the following steps:

[0038] S1. Uniformly disperse polyvinyl alcohol powder in an aprotic solvent according to a preset mass volume ratio to obtain a polyvinyl alcohol solution; then, add a predetermined amount of catalyst to the polyvinyl alcohol solution until it is completely dissolved, and then add a predetermined amount The glycidyl methacrylate is stirred evenly, and reacted at 40-60°C for 4-8 hours; finally, precipitation is precipitated and vacuum-dried to obtain methacrylated polyvinyl alcohol;

[0039] S2. Disperse the methacrylylated polyvinyl alcohol obtained in step S1 in an aprotic solvent according to a preset mass-volume ratio, and fully stir until completely dissolved at 30-50° C. to obtain methacrylated polyethylene Alcohol solution; then, add a predetermined amount of succinic anhydride into the methacrylated polyvinyl alcohol solution, s...

Embodiment 1

[0057] A method for preparing a rapid-forming self-healing hydrogel, comprising the steps of:

[0058] S1, the preparation of methacrylylated polyvinyl alcohol:

[0059] Disperse 5 g of polyvinyl alcohol (PVA) powder in 100 mL of dimethyl sulfoxide, stir well at room temperature to obtain a polyvinyl alcohol solution, then add 0.11 g of p-dimethylaminopyridine (DMAP) catalyst, and continue stirring to completely dissolve it. Add 0.32g of glycidyl methacrylate (GMA) to the above polyvinyl alcohol solution, stir for 30min, react at 60°C for 6h, finish the reaction and drop to room temperature, then add a large amount of anhydrous acetone to the above solution, collect A precipitate precipitated out. The precipitate was dried under vacuum at room temperature to obtain methacrylylated polyvinyl alcohol.

[0060] S2, the preparation of carboxylated methacryl polyvinyl alcohol:

[0061] Take 3g of methacrylated polyvinyl alcohol prepared in step S1, disperse it in 90mL of dimethy...

Embodiment 2

[0070] The difference from Example 1 is that 1.2g of carboxylated methacryl polyvinyl alcohol is dissolved in 10mL of deionized water to prepare a precursor solution with a mass volume concentration of 12%, and add it to the precursor solution Add 0.01g 2-hydroxyl-4'-(2-hydroxyethoxy)-2-methylpropiophenone photoinitiator, all the other steps are the same as in Example 1, and Example 2 prepares a physical and chemical double network cross-linked Self-healing hydrogel named 12% PVA-GMA-COOH / Fe 3+ gel.

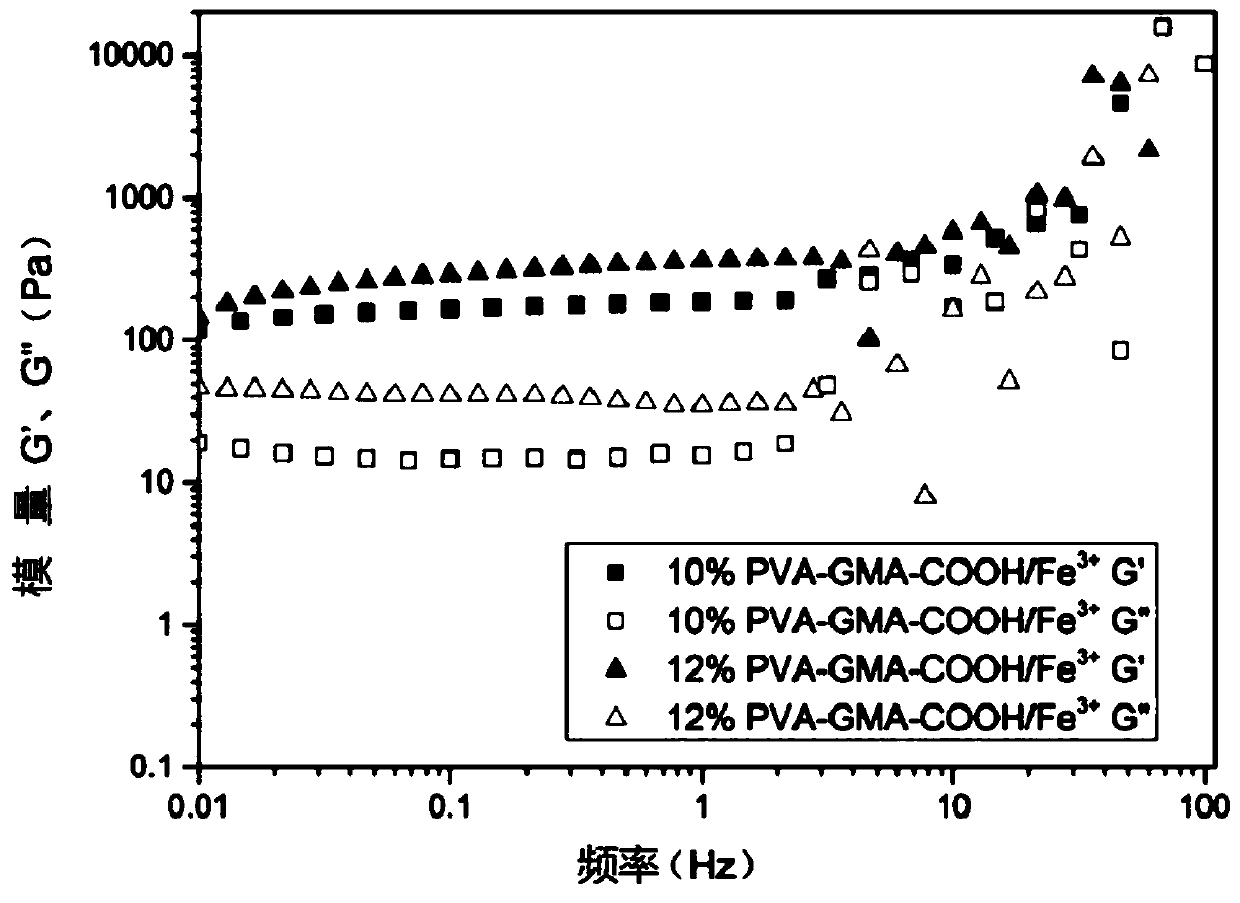

[0071] see image 3 Shown, the 12%PVA-GMA-COOH / Fe that embodiment 2 prepares 3+ 10%PVA-GMA-COOH / Fe prepared by the storage modulus and loss modulus ratio of the gel in Example 1 3+ The high concentration of the gel, which is due to the higher concentration of PVA-GMA-COOH, leads to a higher content of carboxyl groups and double bonds in the mixed solution, forming a denser cross-linked network structure, therefore, improving the strength of the hydrogel.

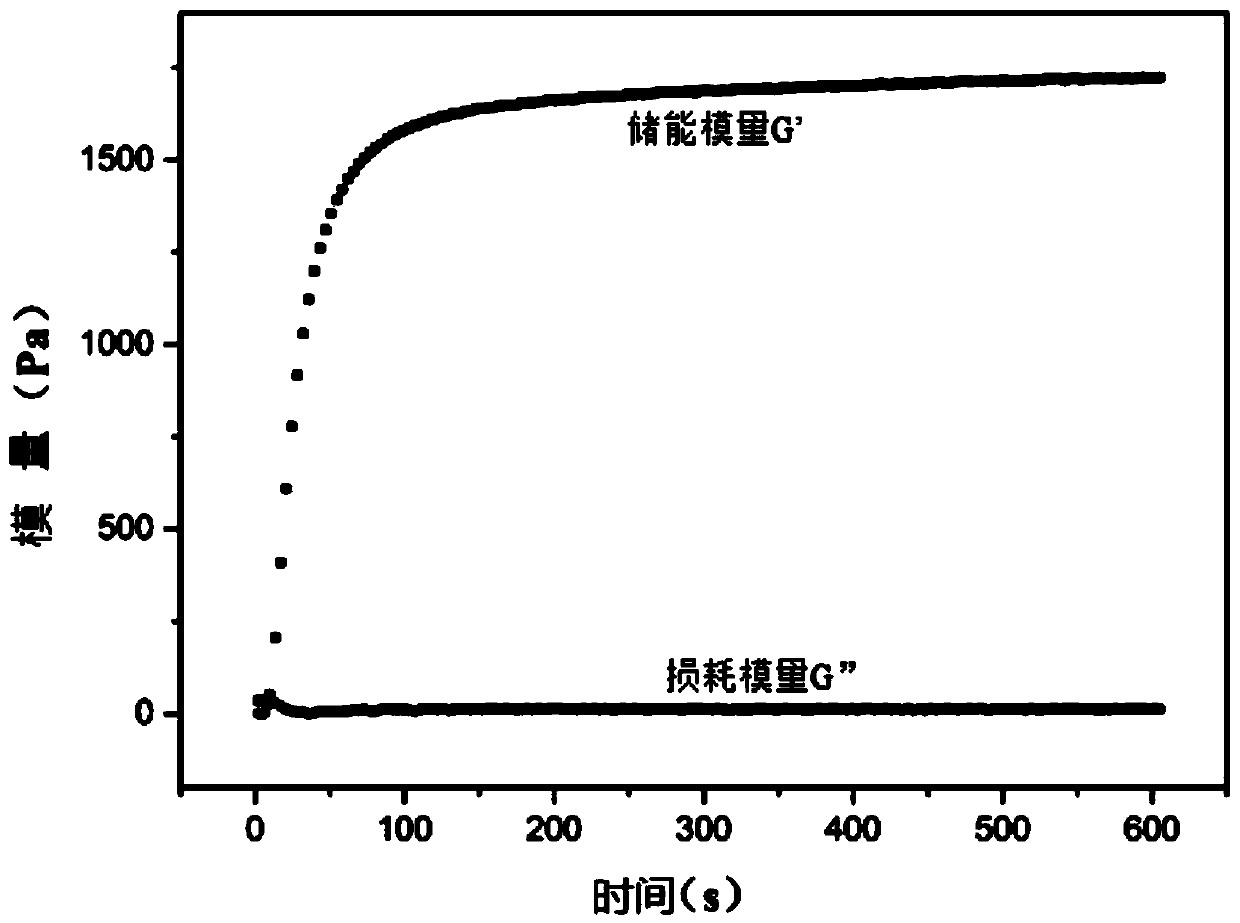

[0072] see Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com