Demethylated lignin liquid modified phenolic resin as well as preparation method and application thereof in phenolic foam

A demethylation and phenolic resin technology, applied in the field of thermal insulation materials, can solve the problems of high price of cetyl tri-n-butylphosphorus bromide and difficulty in industrial application, and achieve reduction of reaction activation energy, strong mechanical properties, The effect of low free formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

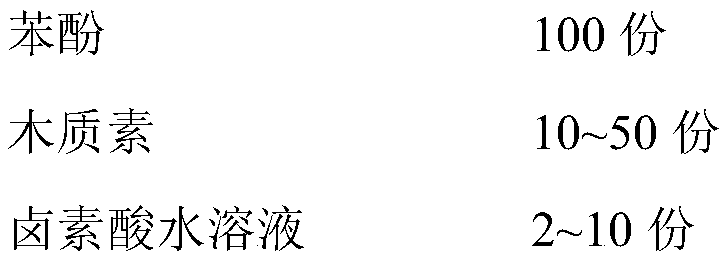

Method used

Image

Examples

Embodiment 1

[0051] Take 100 parts of phenol, add 20 parts of lignin, add 8 parts of hydrobromic acid aqueous solution with a mass fraction of 48%, put the mixture in an atmospheric pressure microwave reactor at 80°C for 2 hours, and cool to 50°C to obtain Methylated lignin liquid; add 30wt% sodium hydroxide aqueous solution to the above-mentioned demethylated lignin liquid, adjust the pH to 8.5-9.0; take 100 parts of phenol, add 45 parts of paraformaldehyde in two batches, 8 parts of basic catalyst (sodium hydroxide) and 35 parts of water, add 50% by mass fraction of paraformaldehyde, 50% by mass fraction of basic catalyst and 50% by mass of water for the first time, heat up to 80°C and react for 1h , add the remaining paraformaldehyde, basic catalyst and water to the reaction solution again, react at 80°C for 0.5h, and cool down to 65°C to obtain the demethylated lignin liquid modified phenolic resin; the phenolic resin The pH value is 8.4, the solid content is 76wt%, the viscosity is 29...

Embodiment 2

[0054] Take 100 parts of phenol, add 30 parts of lignin, add 7 parts of hydrobromic acid aqueous solution with a mass fraction of 48%, put the mixture in an atmospheric pressure microwave reactor at 90°C for 2 hours, and cool to 50°C to obtain the Methylated lignin liquid; add 30wt% sodium hydroxide aqueous solution to the above-mentioned demethylated lignin liquid, adjust the pH to 8.5-9.0; take 100 parts of phenol, add 42 parts of paraformaldehyde in two batches, 8.5 parts of basic catalyst (sodium hydroxide) and 40 parts of water, add 50% by mass fraction of paraformaldehyde, 50% by mass fraction of basic catalyst and 50% by mass of water for the first time, heat up to 90°C and react for 1h , add the remaining paraformaldehyde, basic catalyst and water to the reaction solution again, react at 90°C for 0.5h, and cool down to 65°C to obtain the demethylated lignin liquid modified phenolic resin; the phenolic resin The pH value is 8.5, the solid content is 78wt%, the viscosity...

Embodiment 3

[0057] Take 100 parts of phenol, add 40 parts of lignin, add 6 parts of hydrobromic acid aqueous solution with a mass fraction of 48%, put the mixture in an atmospheric pressure microwave reactor at 100°C for 1.5h, and cool to 50°C to obtain Demethylated lignin liquid; add 30wt% sodium hydroxide aqueous solution to the above demethylated lignin liquid, adjust the pH to 8.5-9.0; add 38 parts of paraformaldehyde in two batches based on 100 parts of phenol , 9 parts of basic catalyst (sodium hydroxide) and 42 parts of water, add the water of the paraformaldehyde of 50% mass fraction, the basic catalyst of 50% mass fraction and 50% mass fraction for the first time, be warming up to 85 ℃ of reaction 1h, add the remaining paraformaldehyde, basic catalyst and water to the reaction solution again, react at 85°C for 0.5h, and cool down to 65°C to obtain the demethylated lignin liquid modified phenolic resin; the phenolic resin The pH value is 8.6, the solid content is 80wt%, the viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com