Preparation method of 3, 4, 5-trimethylhydroquinone dialkanoate

A technology of trimethylhydroquinone dialkanoate and diketone, which is applied in the field of preparation of 3,4,5-trimethylhydroquinone dialkanoate and can solve the problems of poor selectivity and low product yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

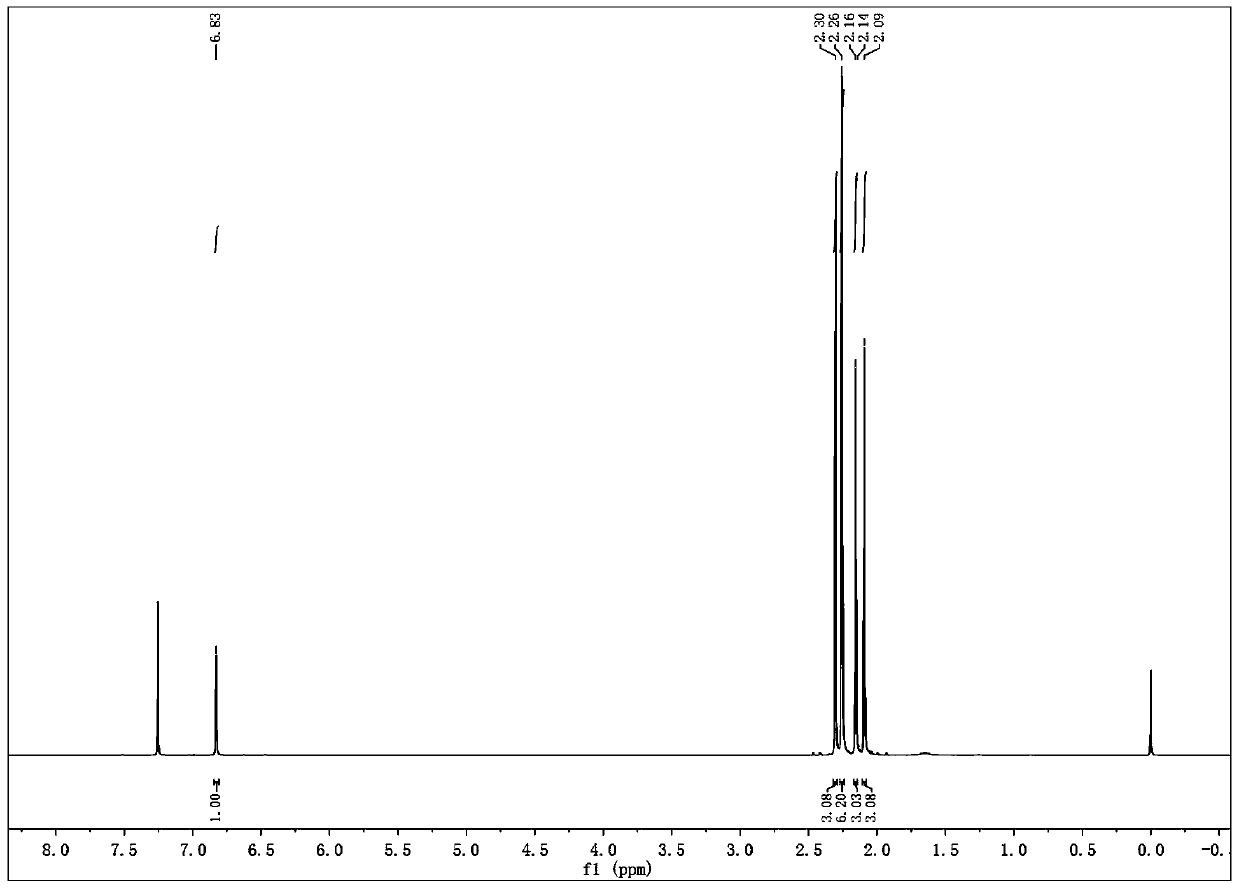

Image

Examples

Embodiment 1

[0033] 40.0g acetic anhydride, 1.0g BF 3 ·OEt 2 Catalyst, 0.0700g 5-hydroxy-6-methylnicotinic acid was placed in a 250mL three-necked flask, mechanical stirring was started, and 20.0g 2,6,6-trimethylcyclohex-2-ene-1,4-di Ketone (99.5% purity, the same below) was slowly dropped into the three-necked flask. The mixture was reacted at a constant temperature of 60°C for 10 hours. After the reaction was completed, the reaction solution was taken for gas chromatography analysis. The conversion rate of the raw material 2,6,6-trimethylcyclohex-2-ene-1,4-dione was 99.3%. The selectivity of the product 3,4,5-trimethylhydroquinone diacetate is 81.4%.

[0034] Cool the reaction solution to -5°C, separate the solid and the solution in the system, add 100.0 g of petroleum ether (90-120) to the obtained solid at 75°C, dissolve it fully, let it stand and cool naturally to 20°C to crystallize, and Keep it standing at 20°C for 8h. The precipitated crystals were filtered, and the filter cake...

Embodiment 2

[0036] Put 38.85g of acetyl chloride, 397.0g of ethanol, 1.7g of phosphoric acid catalyst, and 0.05g of nicotinic acid furfurate into a 1000mL three-necked flask, turn on mechanical stirring, and mix 25.0g of 2,6,6-trimethylcyclohexyl-2- En-1,4-dione was slowly dropped into the three-necked flask. The mixture was reacted at a constant temperature of 80°C for 5 hours. After the reaction was completed, the reaction solution was taken for gas chromatography analysis. The conversion rate of the raw material 2,6,6-trimethylcyclohex-2-ene-1,4-dione was 98.1%. The selectivity of the product 3,4,5-trimethylhydroquinone diacetate is 85.9%.

[0037]Cool the reaction solution to -20°C, separate the solid and solution in the system, add 30.0 g of chlorobenzene and 100 g of ethyl acetate to the obtained solid at 75°C, dissolve it fully, let it stand and cool to 20°C to crystallize naturally, and Keep it standing at 20°C for 8h. The precipitated crystals were filtered, and the filter cake...

Embodiment 3

[0039] 61.1g propionyl chloride, 472.0g cyclohexane, 2.0g FeCl 3 Catalyst, 0.05g 5-hydroxy-6-methylnicotinic acid ethyl ester was placed in a 1000mL three-necked flask, mechanical stirring was started, and 25.0g 2,6,6-trimethylcyclohex-2-ene-1,4 - Slowly drop the diketone into the three-neck flask. The mixture was reacted at a constant temperature of 50°C for 8 hours. After the reaction was completed, the reaction solution was taken for gas chromatography analysis. The conversion rate of the raw material 2,6,6-trimethylcyclohex-2-ene-1,4-dione was 94.9%. The selectivity of the product 3,4,5-trimethylhydroquinone dipropionate is 87.3%.

[0040] Cool the reaction solution to -20°C, separate the solid and the solution in the system, add 20.0 g of ethyl acetate and 120 g of cyclohexane to the obtained solid at 75°C, dissolve it fully, let it stand and cool to 20°C for crystallization, And keep it standing at 20°C for 8h. The precipitated crystals were filtered, and the filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com