Path planning method of wire arc additive manufacturing without lap joints in layers

An additive manufacturing and path planning technology, applied in the field of additive manufacturing, can solve the problems of unstable forming quality, excessive lap joints, and reduced efficiency, so as to reduce the number of arc starting and ending points, and improve the overall quality , to avoid the effect of insufficient mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

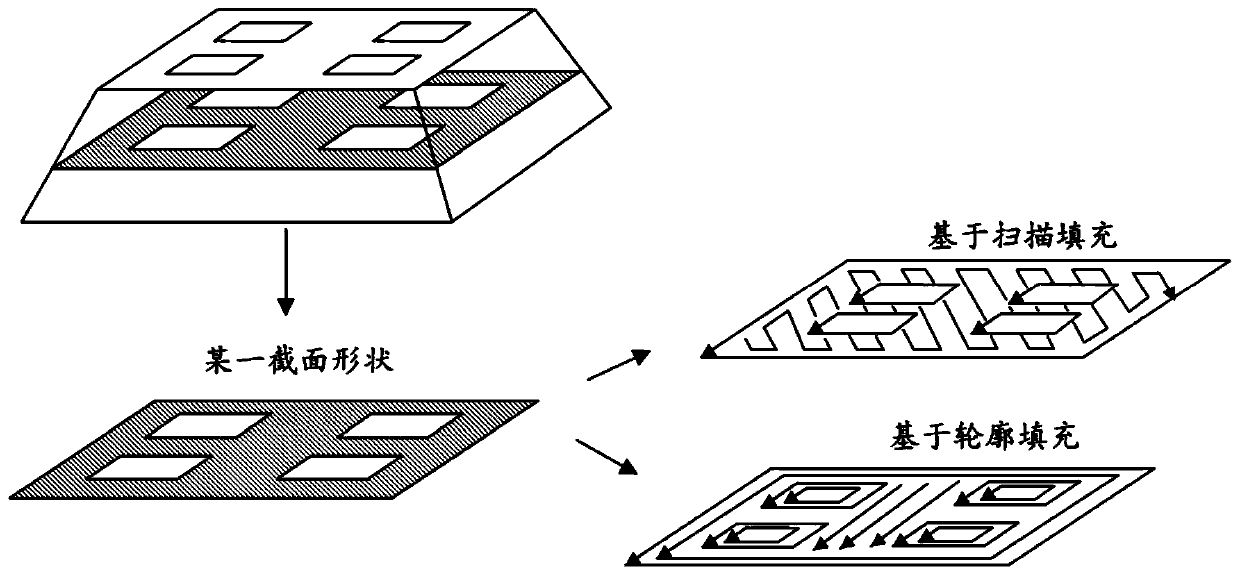

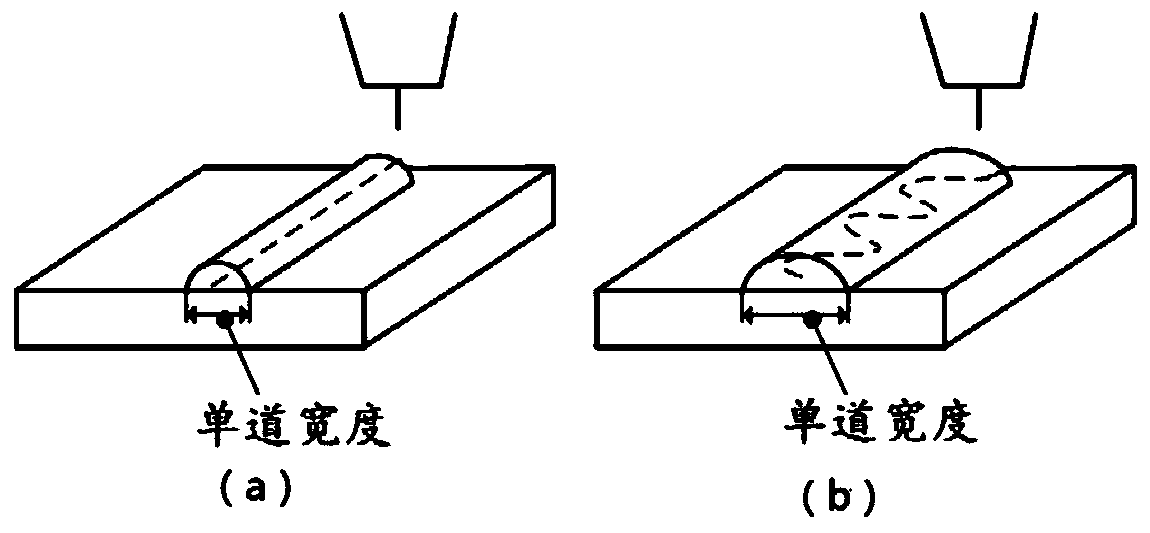

[0044] Such as Figure 7 , the specific implementation steps of arc additive manufacturing path planning are:

[0045] Step 1: Machining allowance design. Since arc additive materials generally form blanks, a certain machining margin is allowed. In order to make the scanning path cover the entire cross-sectional area and to achieve filling through subsequent swings, the cross-sectional shape of the arc additive manufactured structural parts after slicing is approximated as A more regular shape with margins. In this embodiment, firstly, the "cubic trapezoid" on the left side of the structure is simplified into a "cubic rectangle", and the "circular hole" on the right side of the structure is simplified into a "triangular hole", and then the structure is designed as Multiple segments of equal wall thickness for subsequent extraction of linear paths and swing fills. At the same time, all shapes and contours are properly offset outwards to ensure that the structural parts desig...

Embodiment 2

[0050] Using the path planning method in the present invention to implement the arc additive manufacturing of a typical structural part 1 block, structural part 2 ring, and structural part 3 frame, the structure of the structural part is as follows Figure 8 shown.

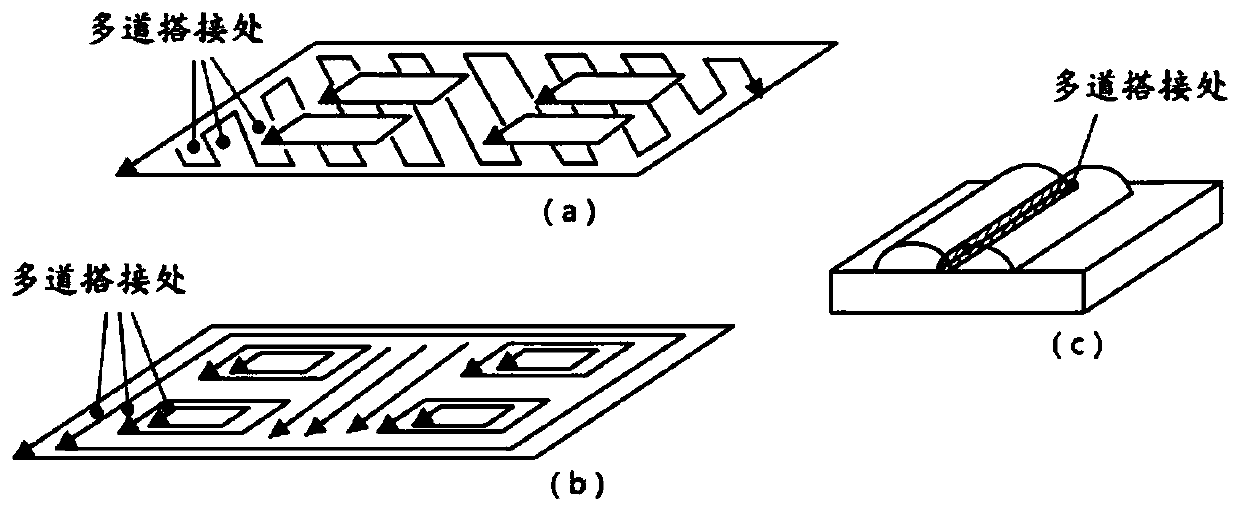

[0051] In contrast, the arc additive manufacturing of structural parts 1 to 3 is implemented using the traditional planning methods based on contour filling method and scanning filling method. The schematic diagrams of the intralayer path planning methods of structural parts 1, 2 and 3 are shown in Fig. Figure 9 , 10 , 11 shown. The parameters of arc additive manufacturing meet the requirements of the present invention.

[0052] According to statistics, compared with the traditional method, the path planning method in the present invention reduces the number of arc starting points and arc ending points, as shown in Table 1. probability of a defect.

[0053] Table 1 The total number of arc starting points and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com