Adaptive cooling device and method for high-speed manufacturing of optical fiber loose tube

A fiber loose and self-adaptive technology, applied in the field of optical cables, can solve the problems of manual adjustment that cannot guarantee the same position, poor surface quality and size of loose tubes, size and excess growth of loose tubes, etc., to achieve dimensional stability and reduce cooling Effect of water loss and improvement of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

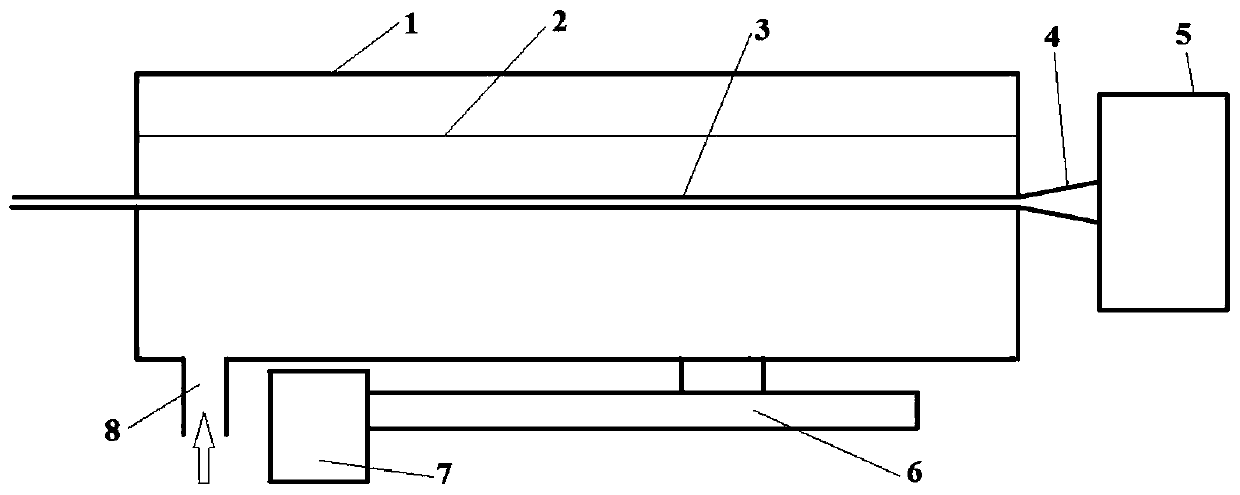

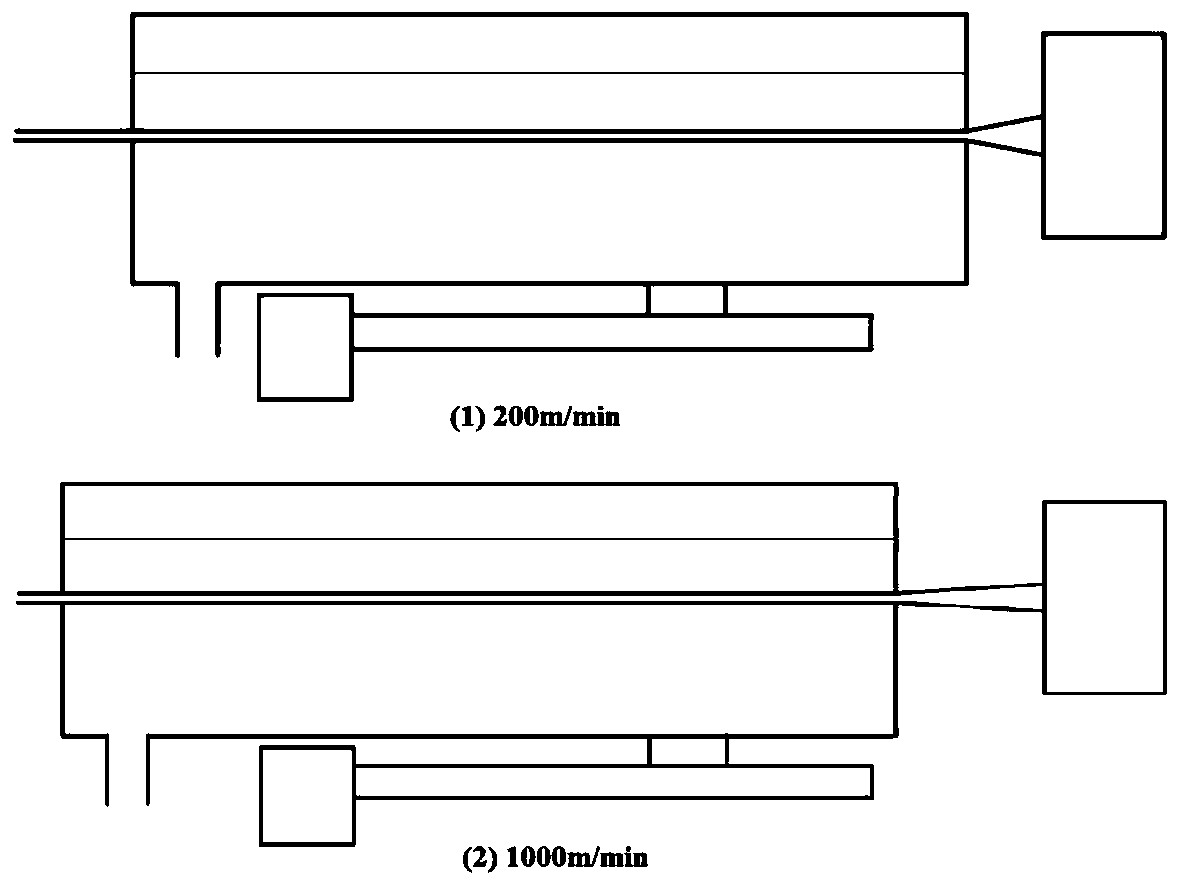

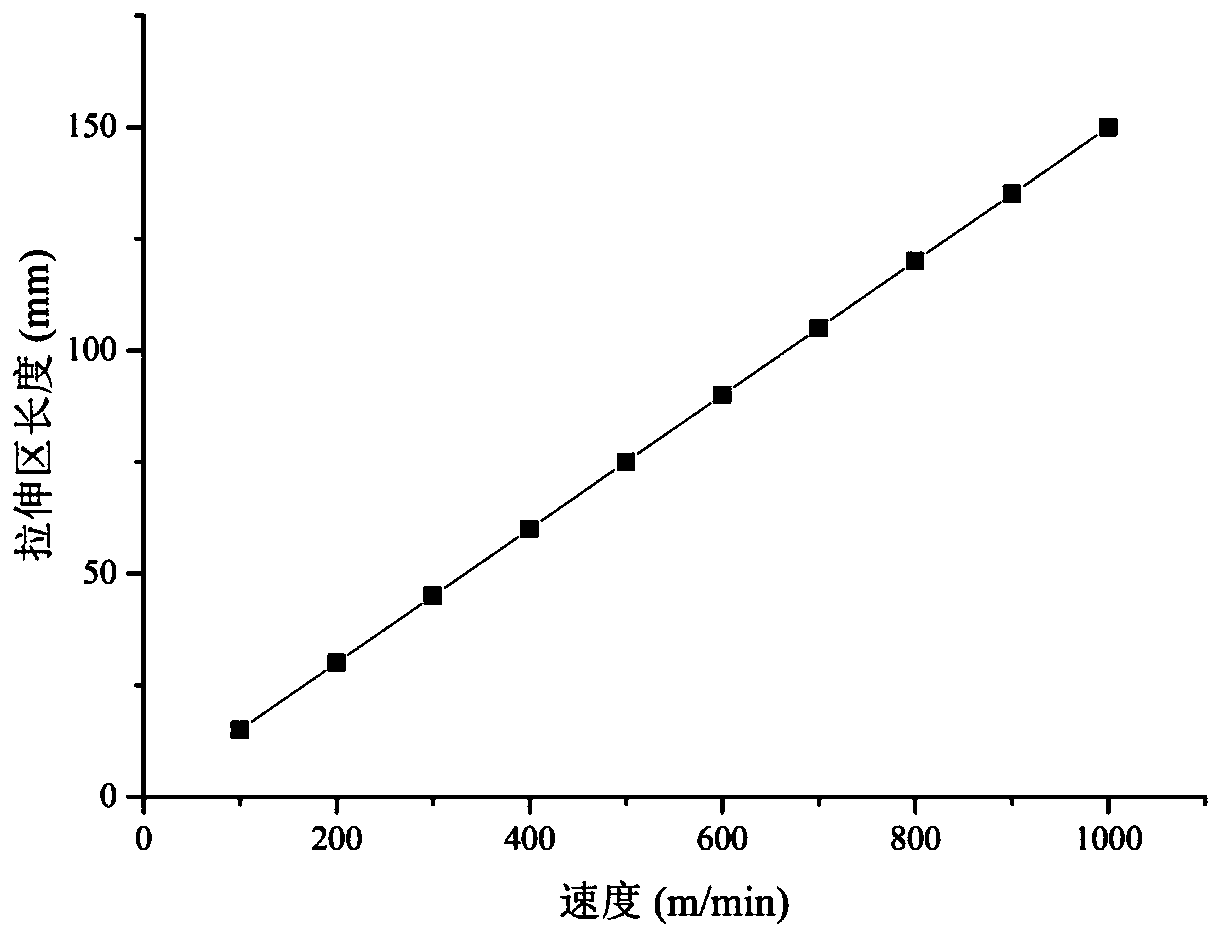

[0037] The adaptive cooling device for high-speed manufacturing of optical fiber loose tubes is placed between the head 5 of the extruder and the main pulley. Zone 4, the section where the end of the stretching zone 4 enters the water tank 1 is called the water inlet surface. After passing through the water inlet surface, the fiber loose tube 3 is cooled and shaped in the water tank 1, and the cooling water 2 is kept by the water volume control unit 8 to immerse the fiber loose tube in real time. The sleeve 3 ensures the surface quality and dimensional accuracy of the optical fiber loose tube 3 . Taking the production of 1.8mm 6-core PBT casing as an example, when the production speed is increased from the conventional 100m / min to a high speed of 1000m / min, the length of the stretching zone 4 is increased from 15mm to 150mm, see image 3 , in order to ensure a qualified water inlet surface, according to Figure 4As shown, after 45s, the ball screw 6 driven by the servo motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com