Efficient disinfecting and killing conveying line

A transmission line, high-efficiency technology, applied in the field of high-efficiency disinfection transmission line, can solve the problems of low disinfection efficiency, low efficiency, penetration function and life expectancy, etc., to achieve improved disinfection transmission efficiency, high ultraviolet intensity, and path controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

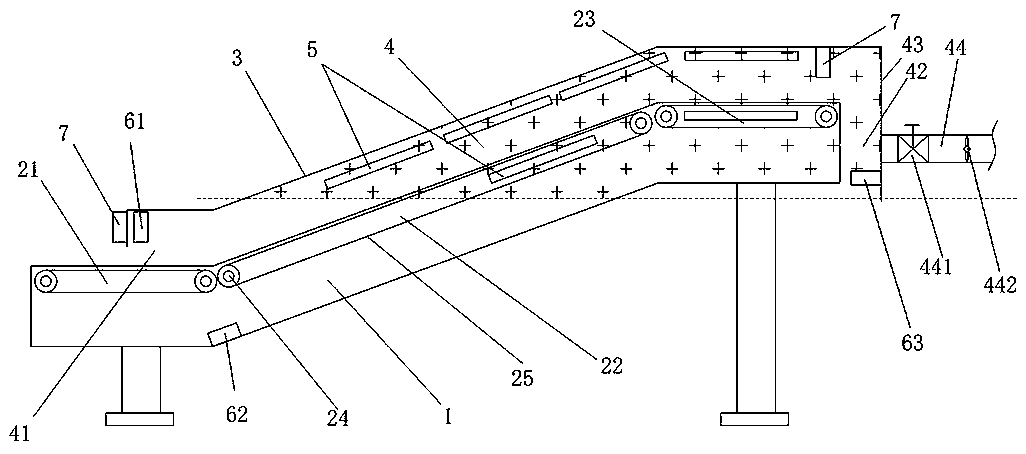

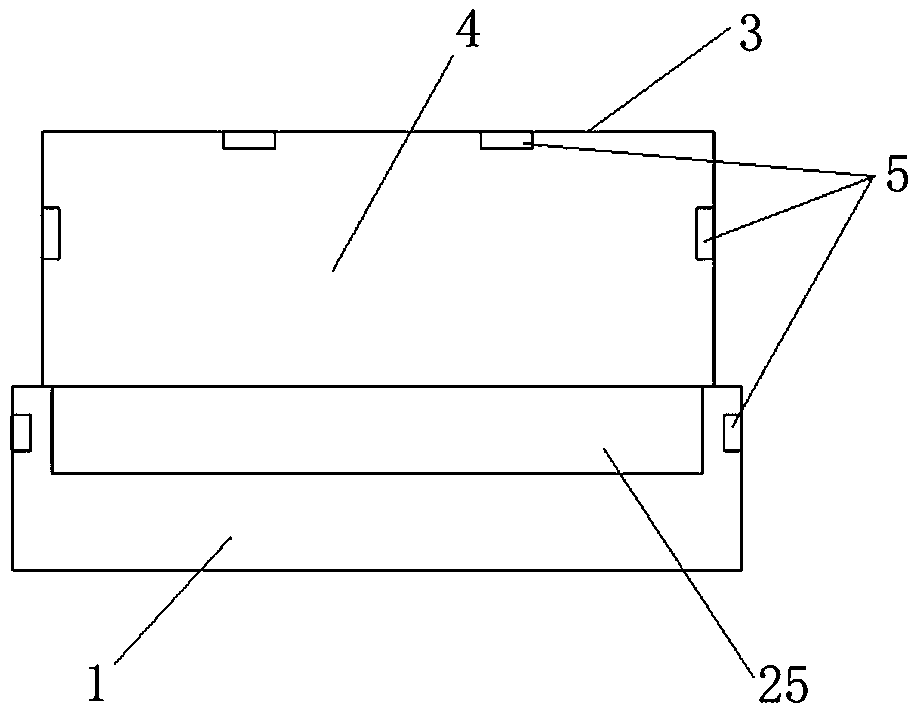

[0030] Such as figure 1 , 2 A high-efficiency disinfecting conveyor line shown in . The support in this embodiment includes a vertical stand arranged from bottom to top and a frame with a concave cross-section installed above the vertical stand and arranged according to the extended shape of the conveying line, and its wall surface is a closed wall surface. The conveyor line has a horizontally arranged feed section 21 and a discharge section 23 positioned at both ends of the conveying direction. The material section 21 is connected to the upwardly inclined connecting section 22 of the discharging section 23, so that the sterilized target material fed from the upstream is formed on this conveying line, and after entering the feeding section 21, it is lifted to the discharging section 23 through the connecting section 22 sent horizontally. The bracket 1 and the housing 3 enclose to form the accommodation chamber 4, the housing 3 and the feeding section 21 enclose to form the ...

Embodiment 2

[0042] Such as Figure 4 As shown, the embodiment described in the second embodiment is similar to the first embodiment, the difference is that:

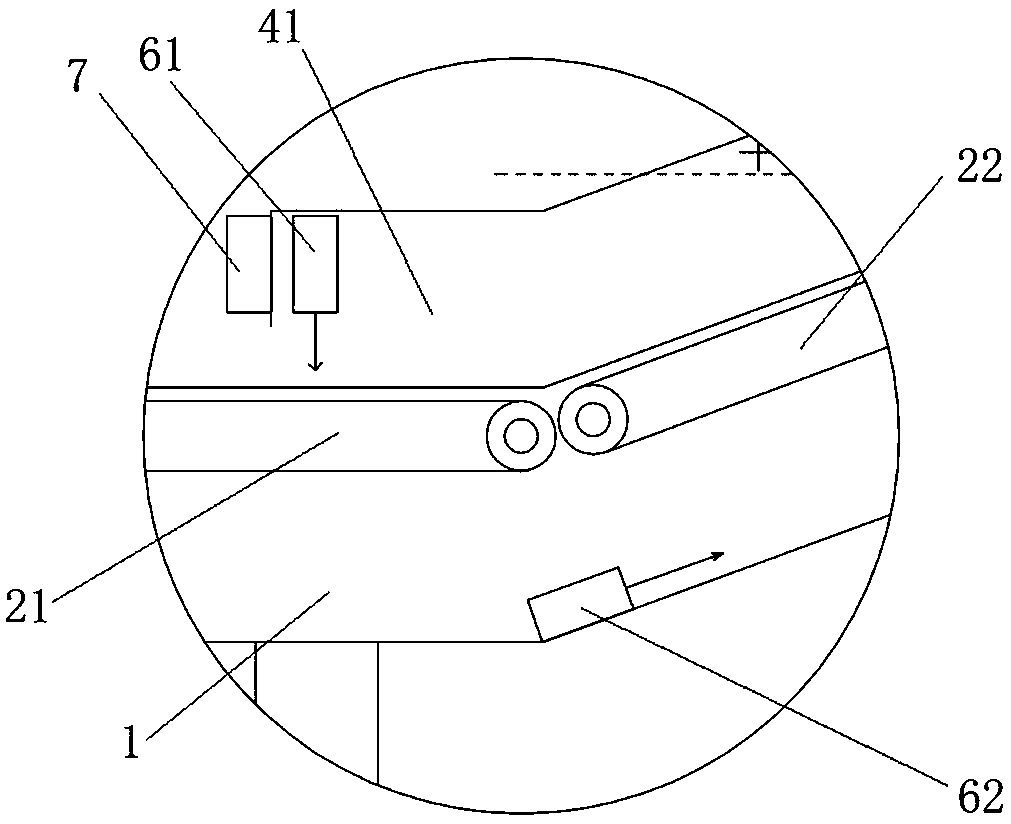

[0043] In this embodiment, it also includes a first air curtain machine 61 and a second air curtain machine 62 located at the entrance 41, the first air curtain machine 61 is located at the housing 3 at the entrance 41 and points to the conveying line below, the first There is a 10° angle between the plane where the air supply direction of the tuyere of the air curtain machine 61 is located and the vertical plane perpendicular to the conveying line, which is biased towards the direction of the accommodation chamber 4, and the angle realizes the air supply obliquely to the conveying line at the entrance, and further When encountering a certain obstacle on the surface of the conveying line, it presents a reflection-shaped air path toward the connecting section 22 in the housing chamber, thereby further preventing the downward loss of oz...

Embodiment 3

[0045] Such as Figure 5 As shown, the specific implementation manner of embodiment three is similar to embodiment one, and its difference is:

[0046] In this embodiment, the connecting section 22 provided between the feeding section 21 and the discharging section 23 has a trapezoidal structure starting from the rear side of the feeding section 21, which is inclined-horizontal-downward and connects the discharging section 23. Under this structure, the formed accommodating chamber 4 and the ozone concentration line therein have a better ability to maintain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com