Ultrasonic-enhanced airflow drying system

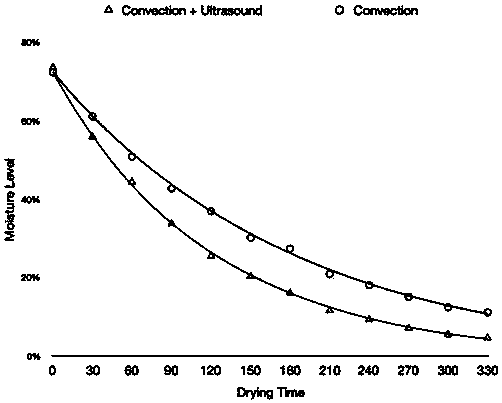

An airflow drying and ultrasonic technology, applied in food processing, food science, application, etc., can solve the problems of active ingredient destruction, uneven drying, low energy efficiency, etc., and achieve the goal of reducing energy consumption, avoiding the loss of active ingredients, and fast drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

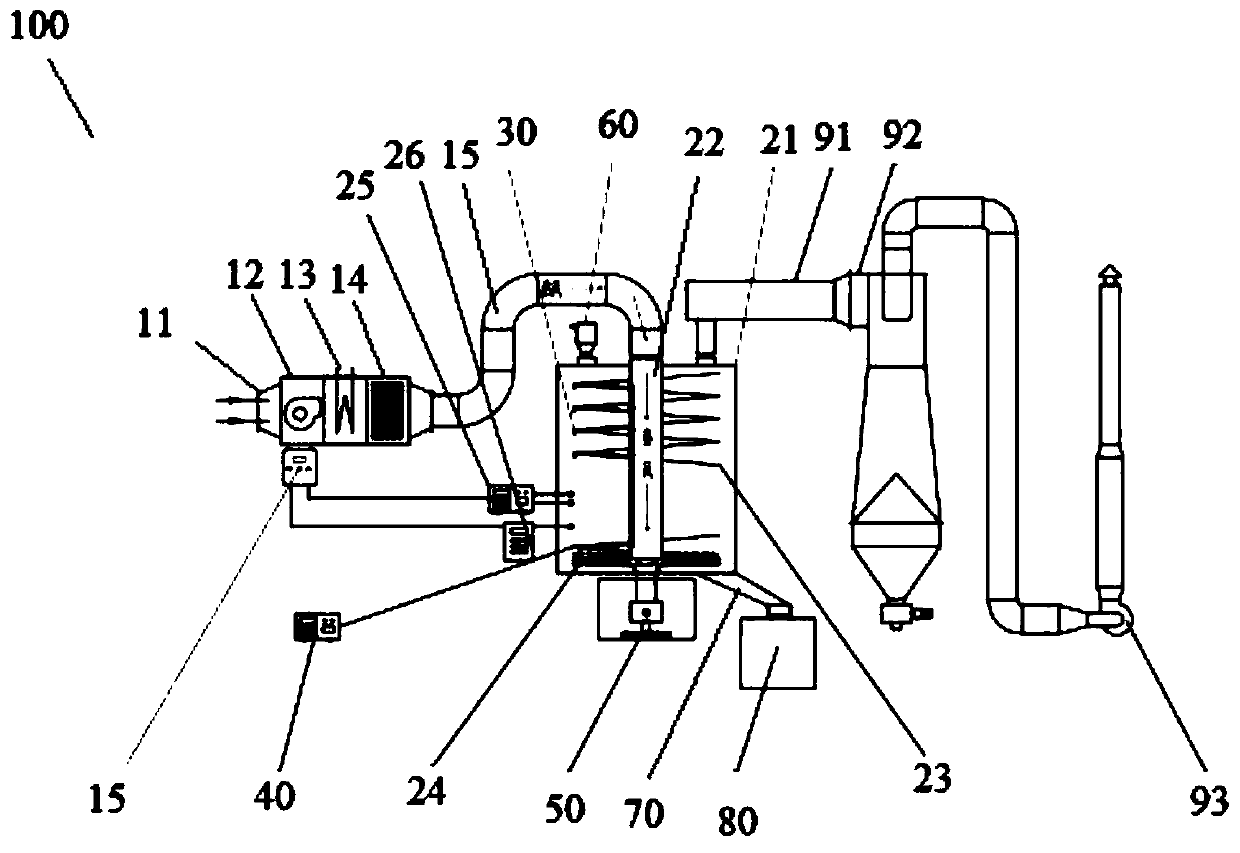

[0015] figure 1 It is a schematic diagram of the overall structure of the ultrasonic-enhanced airflow drying system in the embodiment of the present invention.

[0016] like figure 1 As shown, an ultrasonic-enhanced airflow drying system 100 in this embodiment includes an air supply module 10, a drying chamber 20, an ultrasonic transducer 30, an ultrasonic generator 40, a support base 50, a vacuum feeder 60, a material guide The tank 70 , the receiving bin 80 and the exhaust module 90 .

[0017] The air supply module 10 includes an air supply port 11 connected in sequence, a fan section 12 for introducing air, a heating section 13 for heating air, a filter section 14 for filtering and humidifying air, and for outputting heated and filtered air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com