Carbon fiber reinforcing method for variable cross-section crane beam

A technology of carbon fiber reinforcement and crane girder, which is applied in the direction of building maintenance, construction, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

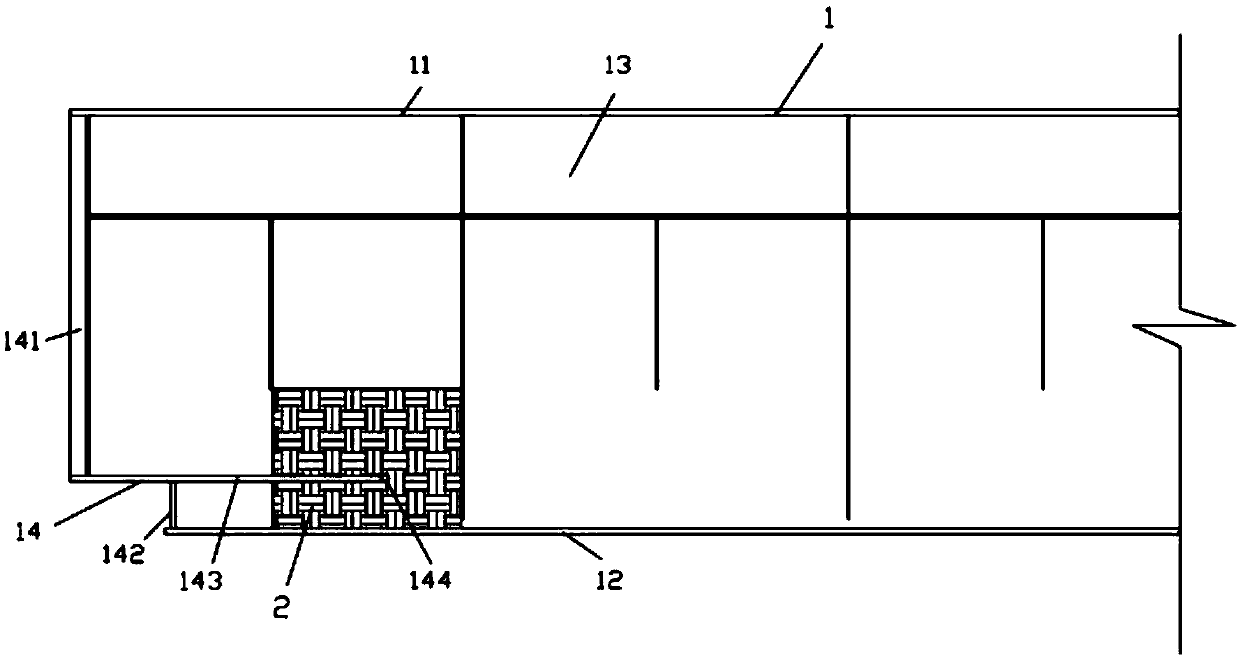

[0024] see Figure 1 ~ Figure 3 , a carbon fiber reinforcement method of variable cross-section crane girder of the present invention, it comprises the following steps:

[0025] 1) Grind and smooth the cracked components in the area where carbon fiber cloth CFRP needs to be pasted, and remove floating dust and dust on the surface;

[0026] 2) Cut the carbon fiber cloth according to the size of the reinforcement design, then paint the carbon fiber cloth soaked in the adhesive, fix the carbon fiber cloth on the sticking part, and then use the roller to roll in one direction along the direction of the carbon fiber cloth to eliminate its internal hollowing.

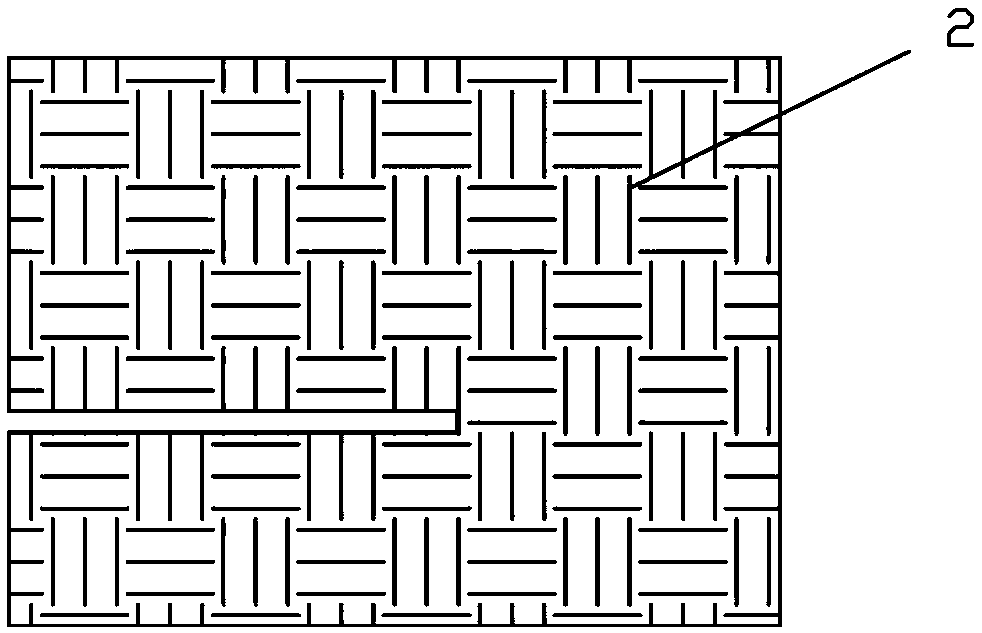

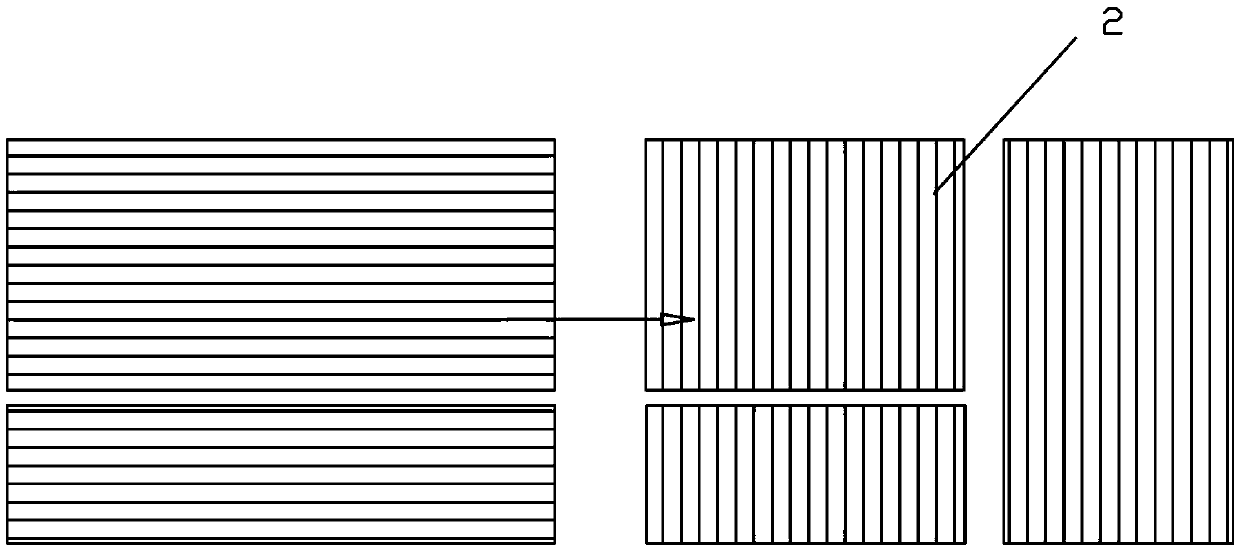

[0027] Preferably, in step 2), the carbon fiber cloth is pasted in two layers, the direction of the lower layer of carbon fiber cloth is pasted along the axial direction of the crane beam, and the direction of the pattern of the upper layer of carbon fiber cloth is perpendicular to the direction of the pattern of the lower la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com