Rotary electrochemical reactor

An electrochemical and reactor technology, which is applied in the field of rotary electrochemical reactors, can solve the problems affecting the reaction efficiency of reacting substances, and the mass transfer effect of electrochemical reactors is not good enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

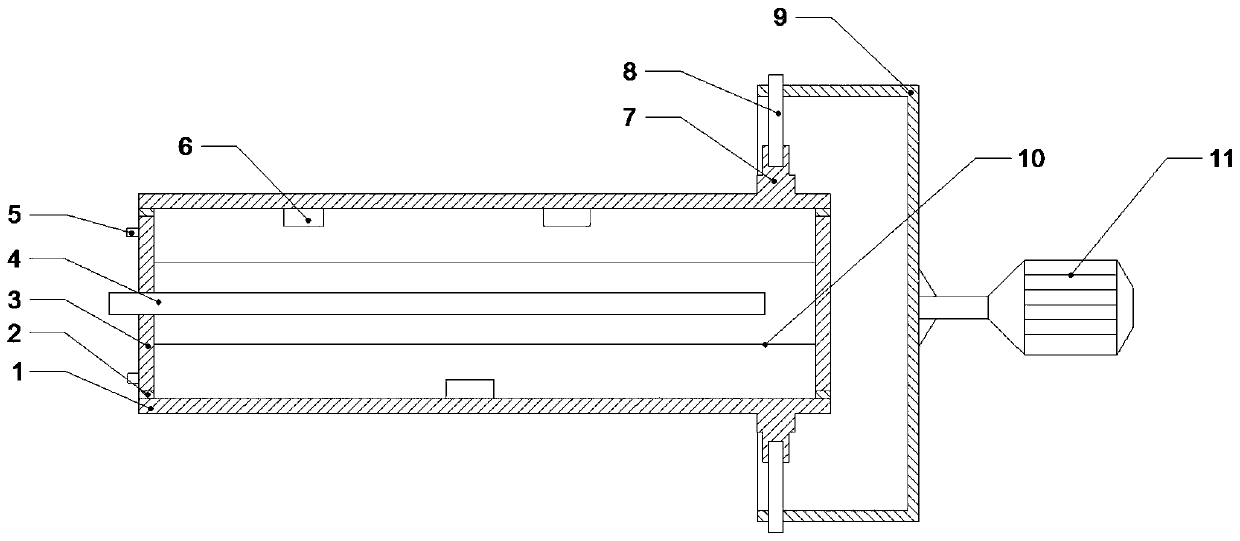

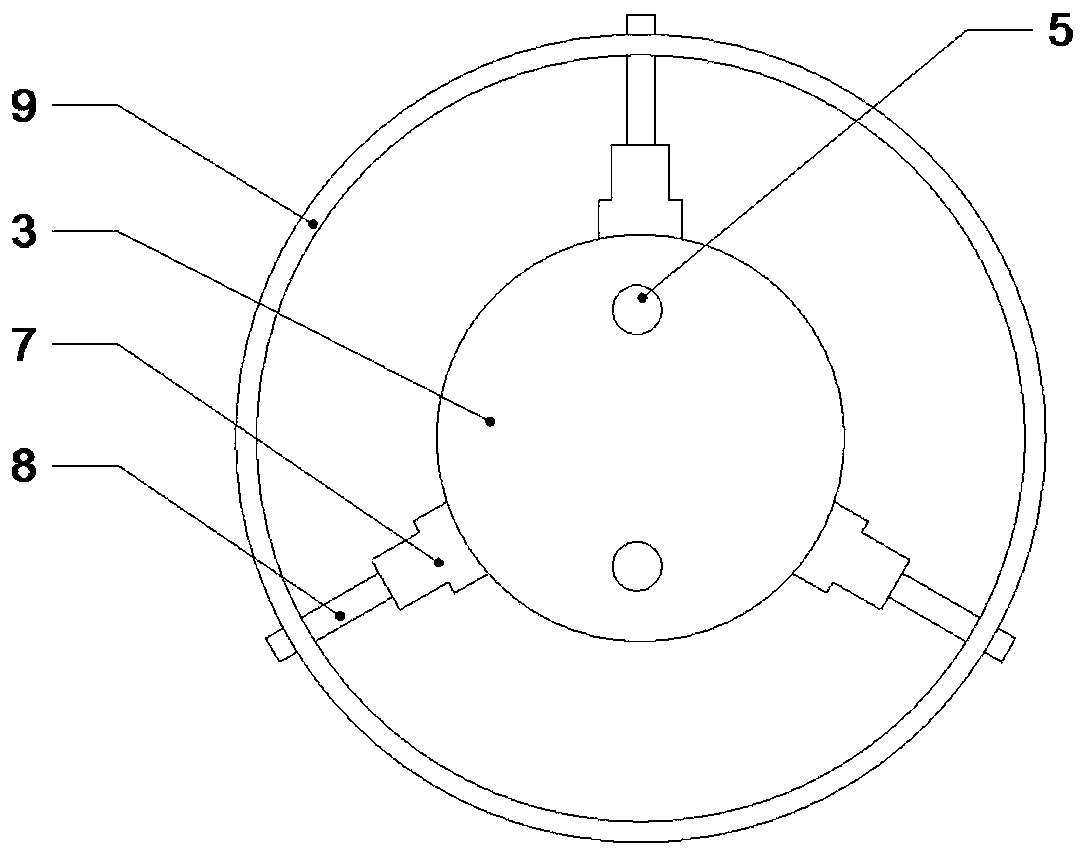

[0028] Such as Figure 1-2 Shown, a kind of rotary electrochemical reactor comprises shell 1, has a plurality of interface 5 on shell 1, and shell 1 is cathode, and the two ends of shell 1 are installed with sealing cap 3 through sealing ring 2, and shell 1 is equipped with There is an anode 4, and a rotating device that can rotate the casing 1 is detachably installed on the casing 1.

[0029] Working principle: The material of the anode 4 is selected according to the solution system of the electrochemical reaction. For example, the sulfuric acid-sulfate system can use lead and lead alloy materials or titanium-based lead dioxide electrodes; the hydrochloric acid-chloride system can use graphite materials or ruthenium Coated electrodes; stainless steel or nickel electrodes can be used for sodium hydroxide system, and the shape can be rod or tube.

[0030] When the corresponding solution needs to be reacted, the solution can be injected into the shell 1 through the interface 5,...

Embodiment 2

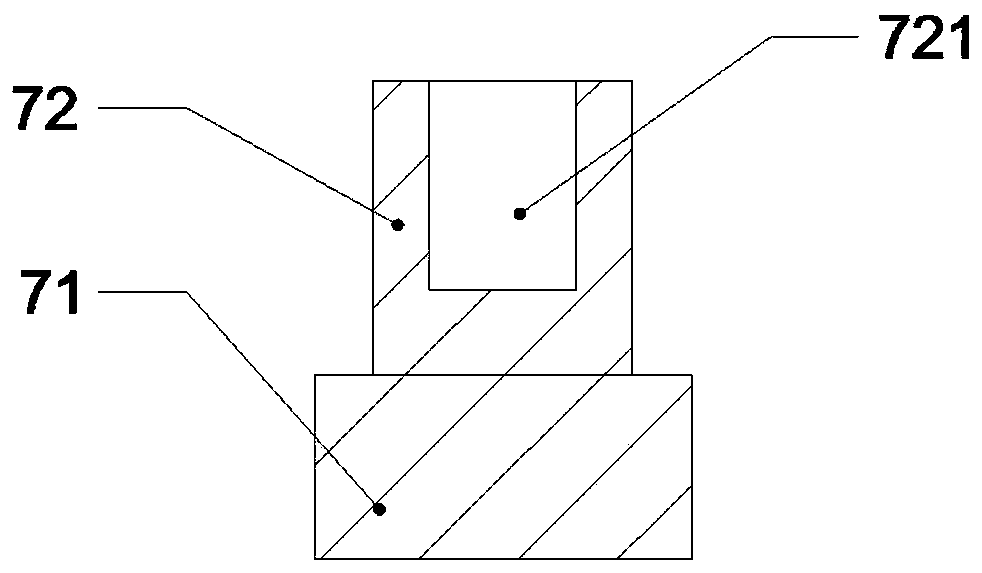

[0032] Such as Figure 1-4 As shown, on the basis of the above-mentioned embodiments, this embodiment provides a preferred structure of the last stirring layer, that is, a plurality of connecting handles 7 are uniformly arranged on the circumferential surface of the shell 1, and the rotating device includes a connecting handle 7 corresponds to the connecting rod 8 one by one, one end of the connecting rod 8 is detachably connected to the connecting handle 7, and the other end is connected to the connecting cone 9, and the connecting cone 9 is connected to the rotating motor 11; the connecting handle 7 is integrally formed with the shell 1, connected The handle 7 includes a connecting piece 71 and a connecting protrusion 72 formed integrally with each other. A connecting hole 721 is provided in the connecting protrusion 72. The connecting rod 8 is threadedly connected to the connecting hole 721. The connecting rod 8 passes through the connecting cone 9 and is connected to the T...

Embodiment 3

[0040] Such as Figure 1-4As shown, on the basis of the above-mentioned Examples 1 and 2, this example takes the removal of copper in industrial dust as an example to illustrate the specific usage of the electrical reactor. That is, an industrial dust contains 4.5% copper and 11% zinc. A graphite rod is used as the anode 4, a titanium tube is used as the shell 1 and the cathode, and the diaphragm 10 is made of polyester filter cloth to form the above-mentioned equipment, and the industrial dust is mixed with 4mol / L ammonium chloride solution to form a suspension, and the In this device, connect the DC power supply, the shell 1 is connected to the negative pole of the power supply, and the graphite rod is connected to the positive pole of the power supply, then the power is turned on, and the voltage is adjusted to 2.35V. After a period of time, the suspension is released, filtered, and the copper content in the test filter residue is ≤0.05%. , the inner wall of the titanium t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com