Process method for smelting high purity steel through VD vacuum treatment device

A technology of vacuum treatment and process method, applied in the direction of manufacturing converters, etc., can solve problems such as inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

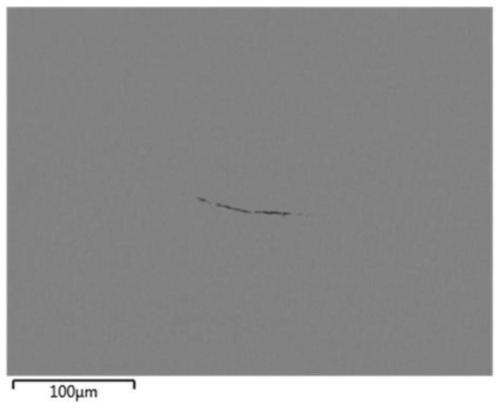

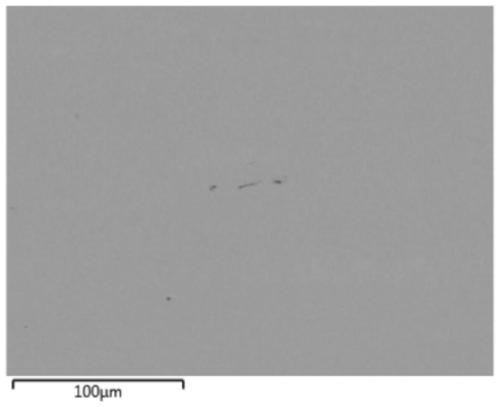

Image

Examples

example 1

[0052] 20CrMo, the mass percentage ω[C] of C in steel is 0.20%, and it is produced by molten iron desulfurization → LD → LF → VD process. Specifically include the following steps:

[0053] 1) Use molten iron with a mass percentage ω[S] of 0.019% of S as raw material, use KR to stir and desulfurize, and the S content of molten iron before entering the furnace is 16ppm;

[0054] 2) Smelting in a 90T top-bottom combined blowing converter, the mass percentage ω[C] of tapping C is 0.08%, the free oxygen content of molten steel is 500ppm when tapping, and the ratio of 1.65kg / t to the furnace before tapping is 30t Add aluminum cake for rapid deoxidation, and the mass percentage ω[Al] of Al at the refining station is 0.067%;

[0055] 3) LF refining slagging: add lime and pre-melted refining slag each 500kg / furnace to make slagging, LF refining process uses silicon carbide to deoxidize the slag surface, the dosage is 180kg / furnace, uses quartz sand 200kg / furnace to adjust the slag com...

example 2

[0061] 20CrMo, the mass percentage ω[C] of C in steel is 0.20%, and it is produced by molten iron desulfurization → LD → LF → VD process. Specifically include the following steps:

[0062] 1) Use molten iron whose mass percentage ω[S] of S is 0.021% as raw material, use KR to stir and desulfurize, and the S content of molten iron before entering the furnace is 20ppm;

[0063] 2) Smelting in a 90T top-bottom double-blown converter, the mass percentage ω[C] of tapping C is 0.10%, the free oxygen content of molten steel is 330ppm when tapping, and the ratio of 1.49kg / t to the furnace before tapping is 30t Add aluminum cake for rapid deoxidation, and the mass percentage ω[Al] of Al at the refining station is 0.071%;

[0064] 3) LF refining slagging: add lime and pre-melted refining slag each 500kg / furnace to make slagging, LF refining process uses silicon carbide to deoxidize the slag surface, the dosage is 170kg / furnace, uses quartz sand 200kg / furnace to adjust the slag composit...

example 3

[0070] 20CrMo, the mass percentage ω[C] of C in steel is 0.20%, and it is produced by molten iron desulfurization → LD → LF → VD process. Specifically include the following steps:

[0071] 1) Using molten iron with a mass percentage of S ω[S] of 0.022% as raw material, using KR to stir and desulfurize, the S content of the molten iron before entering the furnace is 19ppm;

[0072]2) Smelting in a 90T top-bottom double-blown converter, the mass percentage ω[C] of tapping C is 0.11%, the free oxygen content of molten steel is 310ppm when tapping, and the ratio of 1.43kg / t to the furnace before tapping is 30t Add aluminum cake for rapid deoxidation, and the mass percentage ω[Al] of Al at the refining station is 0.073%;

[0073] 3) LF refining slagging: add lime and pre-melted refining slag each 500kg / furnace to make slagging, LF refining process uses silicon carbide to deoxidize the slag surface, the dosage is 160kg / furnace, uses quartz sand 200kg / furnace to adjust the slag comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com