Device and method for preparing 2, 5-furandicarboxylic acid from hexose diacid (hexose diacid salt) by coupling dehydration cyclization reaction and azeotropic distillation dehydration

A technology of furandicarboxylic acid and cyclization reaction, applied in chemical instruments and methods, azeotropic distillation, separation methods and other directions, can solve problems such as reduction and impact on yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

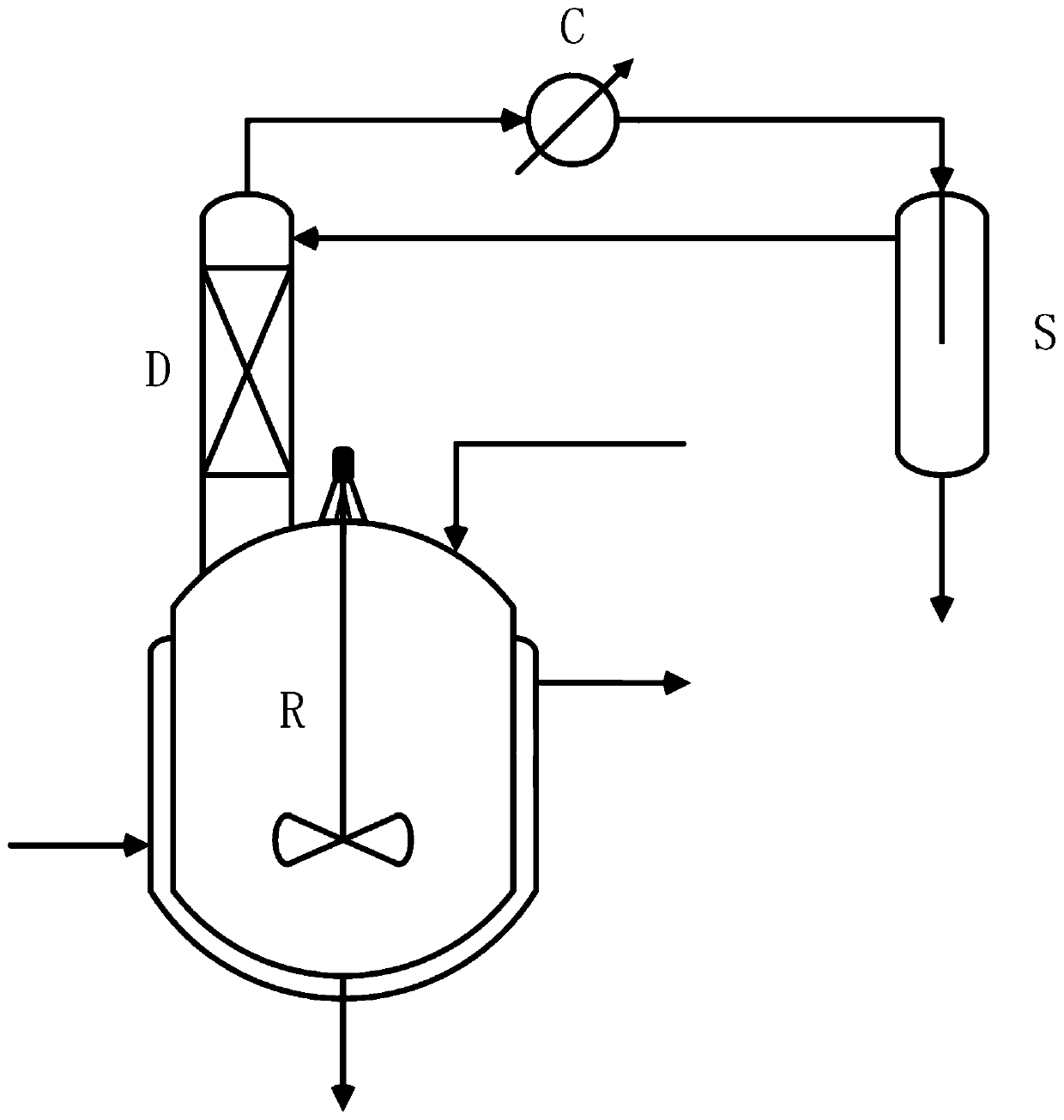

[0026] The first aspect of the present invention provides a device for preparing 2,5-furandicarboxylic acid from hexaric acid (salt) coupled with dehydration cyclization reaction and azeotropic distillation to remove water. The device includes the following components: dehydration cyclization Reactor R, rectification tower D, condenser C, phase separator S, wherein the dehydration and ring closure reactor R is connected to rectification tower D, and the top of rectification tower D is connected to condenser C and phase separator S, and phase separator S is connected with rectification column D.

[0027] The second aspect of the present invention provides a method for preparing 2,5-furandicarboxylic acid from hexaric acid (salt) coupled with dehydration ring closure reaction and azeotropic distillation to remove water, the method comprising the following steps:

[0028] 1) Open the reactor to stir and heat the reactor jacket to heat the steam, and add reaction solvent, hexaric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com