Production process of high-activity desulfurizer slaked lime

A production process and technology of slaked lime, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of high operating cost and hidden safety hazards, and achieve the effect of excellent flow performance, reduced water consumption for digestion, and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

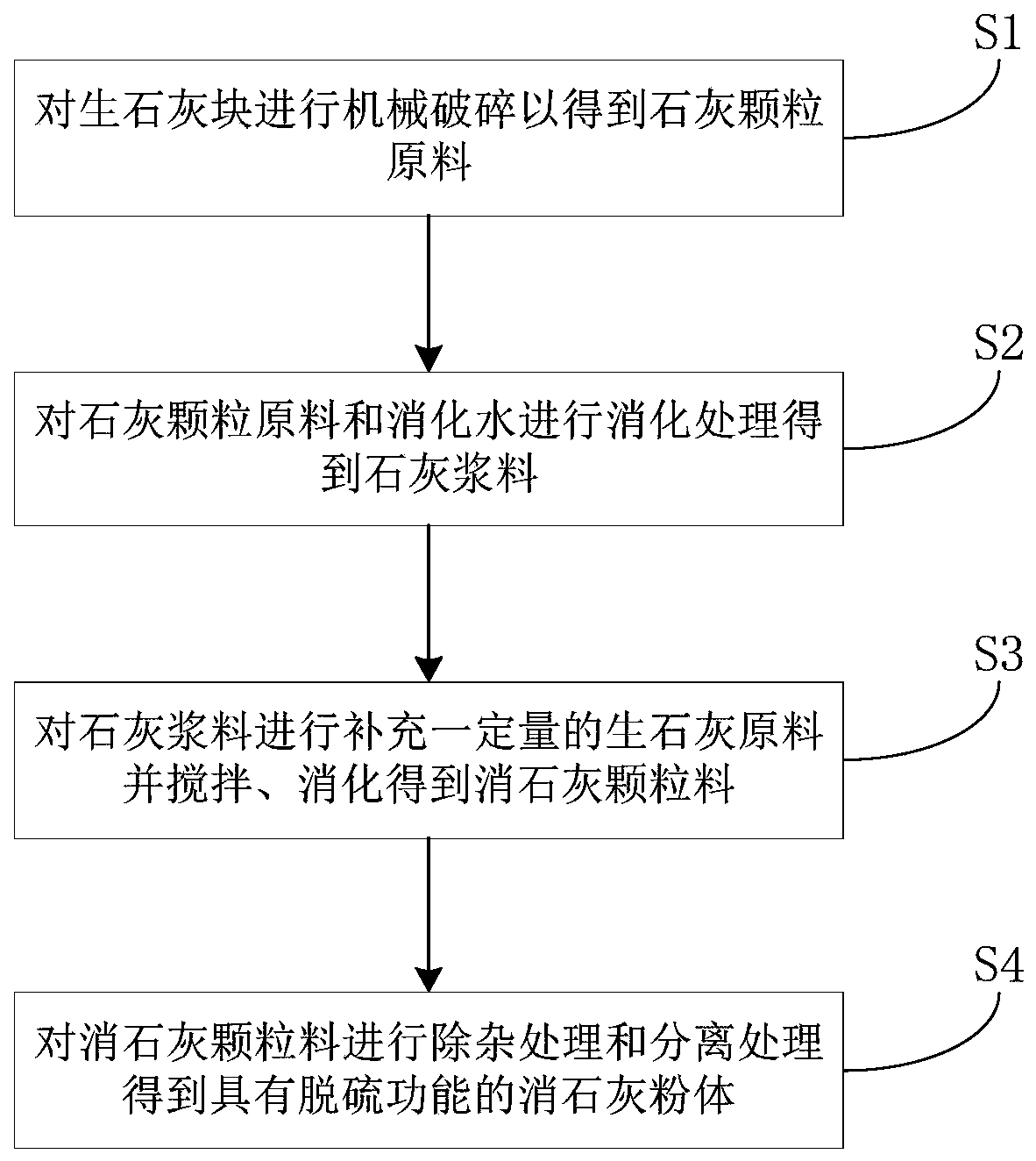

[0026] like figure 1 Shown, a kind of highly active desulfurizer slaked lime production process, comprises:

[0027] S1. Crushing: Put the quicklime block into the pulverizer through the silo for crushing to obtain the raw material of quicklime particles with a particle size of 2mm. processing in one step.

[0028] S2. Pre-digestion: put the quicklime particle raw material and digested water obtained in S1 into a vertical digester and mix them thoroughly for digestion to obtain lime slurry. In this step, the digestion temperature is 50° C., the digestion time is 10 min, and the digestion water includes by mass parts: 0.1% calcium ion complexing agent, 0.5% dispersant, and the rest is water. The rotating speed of the vertical digester is 60r / min.

[0029] S3. Secondary lime addition: Put the lime slurry obtained in S2 into a horizontal spiral stirring digester, add a certain amount of quicklime raw material again, fully stir and continue to digest to obtain slaked lime pelle...

Embodiment 2

[0032] A process for producing hydrated lime as a highly active desulfurizer, comprising:

[0033] S1. Crushing: Put the quicklime block into the pulverizer through the silo for crushing to obtain the raw material of quicklime particles with a particle size of 10mm. processing in one step.

[0034] S2. Pre-digestion: put the quicklime particle raw material and digested water obtained in S1 into a vertical digester and mix them thoroughly for digestion to obtain lime slurry. In this step, the digestion temperature is 100° C., the digestion time is 5 minutes, and the digestion water includes by mass parts: 10% calcium ion complexing agent, 3% dispersant, and the rest is water. The rotating speed of the vertical digester is 100r / min.

[0035] S3. Secondary lime addition: Put the lime slurry obtained in S2 into a horizontal spiral stirring digester, add a certain amount of quicklime raw material again, fully stir and continue to digest to obtain slaked lime pellets. In this ste...

Embodiment 3

[0038] A process for producing hydrated lime as a highly active desulfurizer, comprising:

[0039] S1. Crushing: Put the quicklime block into the pulverizer through the silo for crushing to obtain the raw material of quicklime particles with a particle size of 3mm. processing in one step.

[0040] S2. Pre-digestion: put the quicklime particle raw material and digested water obtained in S1 into a vertical digester and mix them thoroughly for digestion to obtain lime slurry. In this step, the digestion temperature is 60° C., the digestion time is 8 minutes, and the digestion water includes by mass parts: 2% calcium ion complexing agent, 1% dispersant, and the rest is water. The speed of the vertical digester is 90r / min.

[0041]S3. Secondary lime addition: Put the lime slurry obtained in S2 into a horizontal spiral stirring digester, add a certain amount of quicklime raw material again, fully stir and continue to digest to obtain slaked lime pellets. In this step, the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com