Sewage treatment microbial carrier and preparation method thereof

A microbial carrier and sewage treatment technology, applied in biochemical equipment and methods, biological water/sewage treatment, light water/sewage treatment, etc., can solve the problems of low sewage treatment efficiency, easy water deterioration, and easy shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

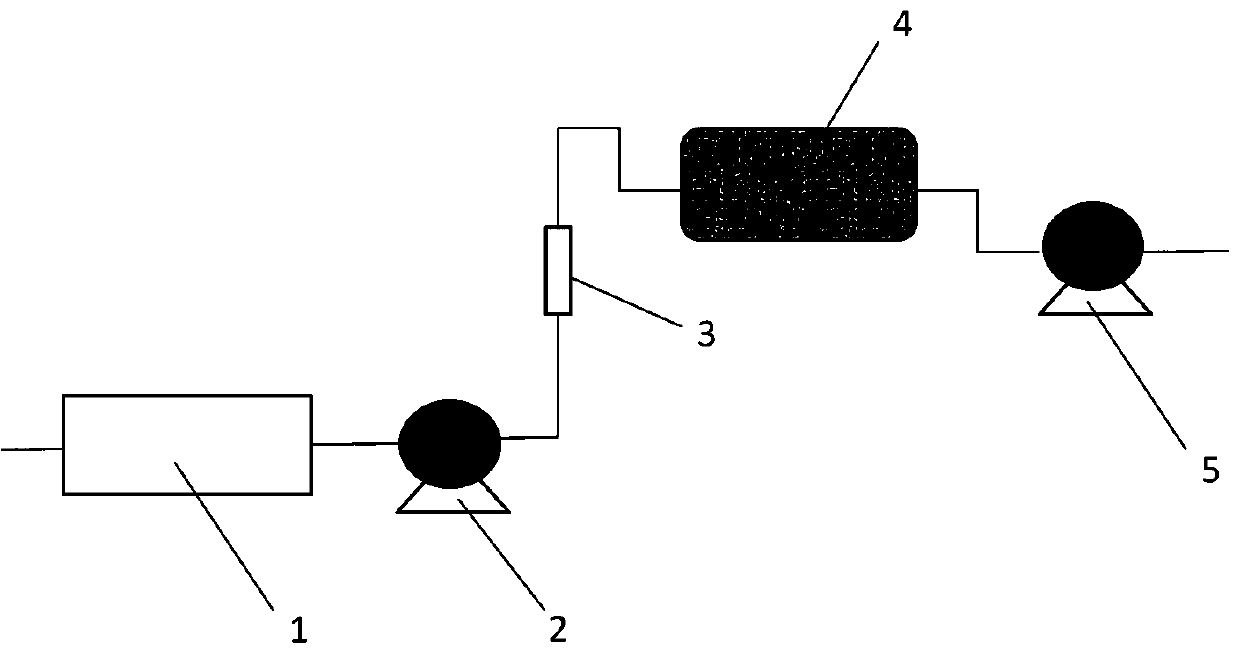

Method used

Image

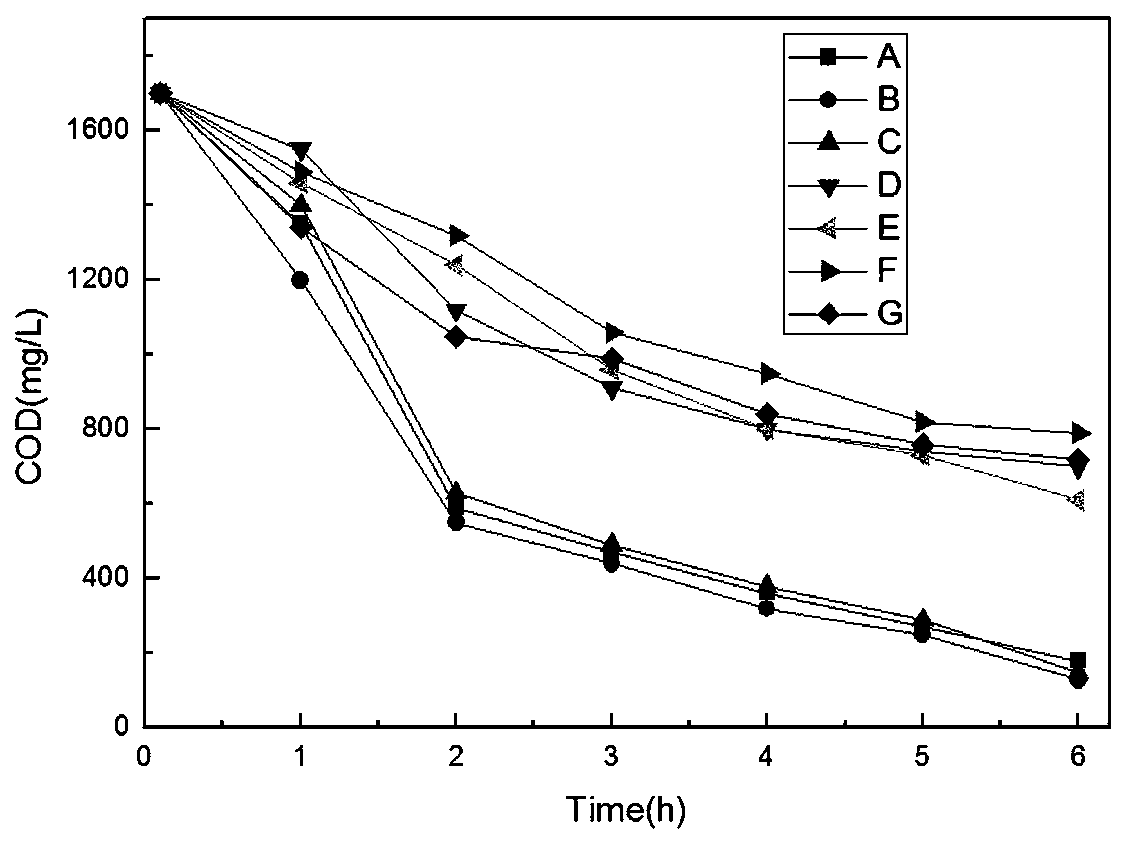

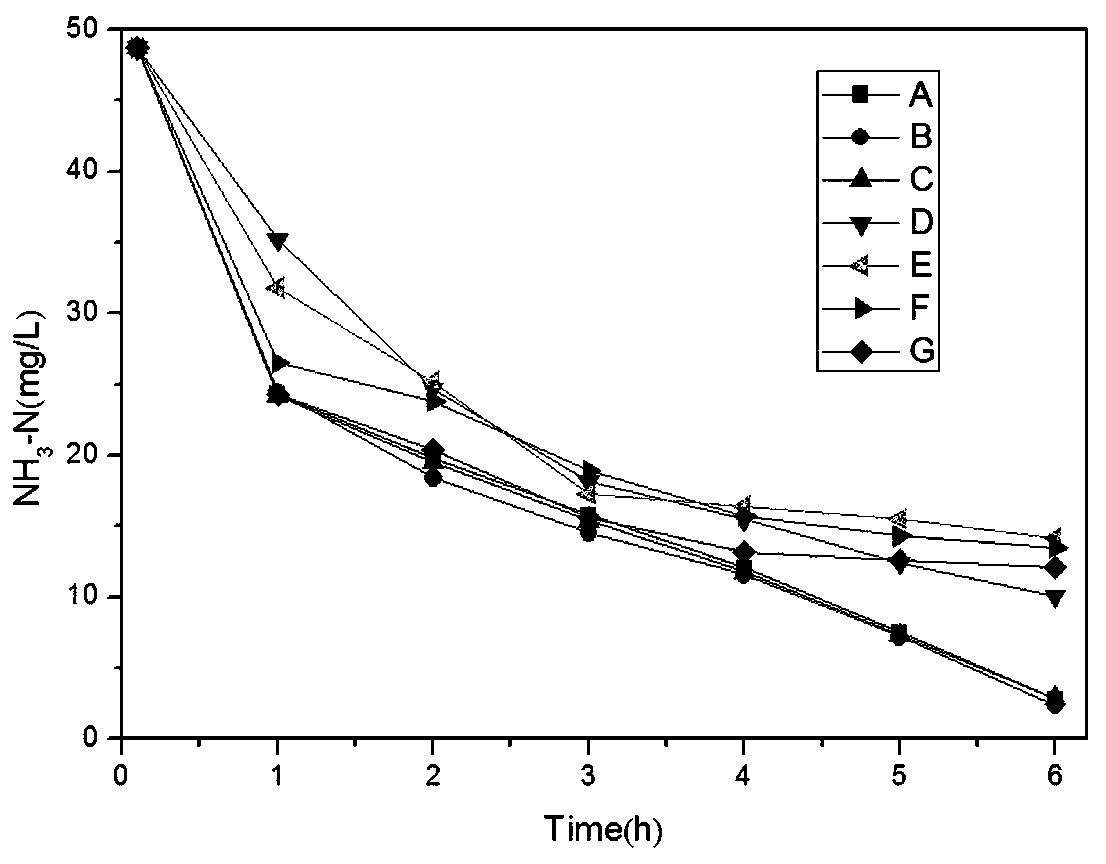

Examples

Embodiment 1

[0032] A method for preparing a microbial carrier for sewage treatment, comprising the following steps:

[0033] Step 1: Add graphene into ethanol, ultrasonically disperse at 30-45°C for 2 hours to obtain graphene solution, then dissolve polyacrylonitrile and ferric citrate in ethanol, mix with graphene solution to prepare spinning solution, and The spinning solution was injected into two identical syringes respectively, and the composite fiber bundle with an average diameter of 5 μm was prepared by the double-needle conjugate method, and then woven to obtain a composite fiber scaffold with a pore diameter of 50 μm. After drying, the JW-RB pore The porosity measured by the porosity measuring instrument is 92%;

[0034] Step 2: Pre-oxidize the composite fiber scaffold obtained in step 1 in an air atmosphere, keep the temperature at 200°C for 4 hours, then place it in an inert gas, program the temperature to 600°C and keep it for 1 hour to complete the carbonization, and stop th...

Embodiment 2

[0037] A method for preparing a microbial carrier for sewage treatment, comprising the following steps:

[0038] Step 1: Add graphene into ethanol, ultrasonically disperse at 30-45°C for 4 hours to obtain a graphene solution, then dissolve polyacrylonitrile and ferric oxalate in ethanol, mix with graphene solution to prepare spinning solution, and spin The silk liquid was injected into two identical syringes respectively, and composite fiber bundles with an average diameter of 8 μm were prepared by double-needle conjugate method, and then weaved to obtain a composite fiber scaffold with a pore diameter of 100 μm. The measuring instrument measures its porosity, which is 94%;

[0039] Step 2: Pre-oxidize the composite fiber scaffold obtained in step 1 in an air atmosphere, keep the temperature at 230°C for 4 hours, then place it in an inert gas, program the temperature to 700°C and keep it for 0.6 hours to complete the carbonization, and stop after the program cools down to 180°...

Embodiment 3

[0042] A method for preparing a microbial carrier for sewage treatment, comprising the following steps:

[0043] Step 1: Add graphene into ethanol, ultrasonically disperse at 30-45°C for 6 hours to obtain graphene solution, then dissolve polyacrylonitrile and ferric citrate in ethanol, mix with graphene solution to prepare spinning solution, and The spinning solution was injected into two identical syringes respectively, and the composite fiber bundle with an average diameter of 10 μm was prepared by double-needle conjugation method, and then woven to obtain a composite fiber scaffold with a pore diameter of 150 μm. After drying, the JW-RB pore The porosity measured by the porosity measuring instrument is 97%;

[0044] Step 2: Pre-oxidize the composite fiber scaffold obtained in step 1 in an air atmosphere, keep the temperature at 200-250°C for 4 hours, then place it in an inert gas, program the temperature to 800°C and keep it for 0.5h to complete the carbonization, and progr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com