Device free of material leaking during mold opening and closing

A technology for opening and closing molds and material leakage, which is applied in the field of injection molds and can solve problems such as material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

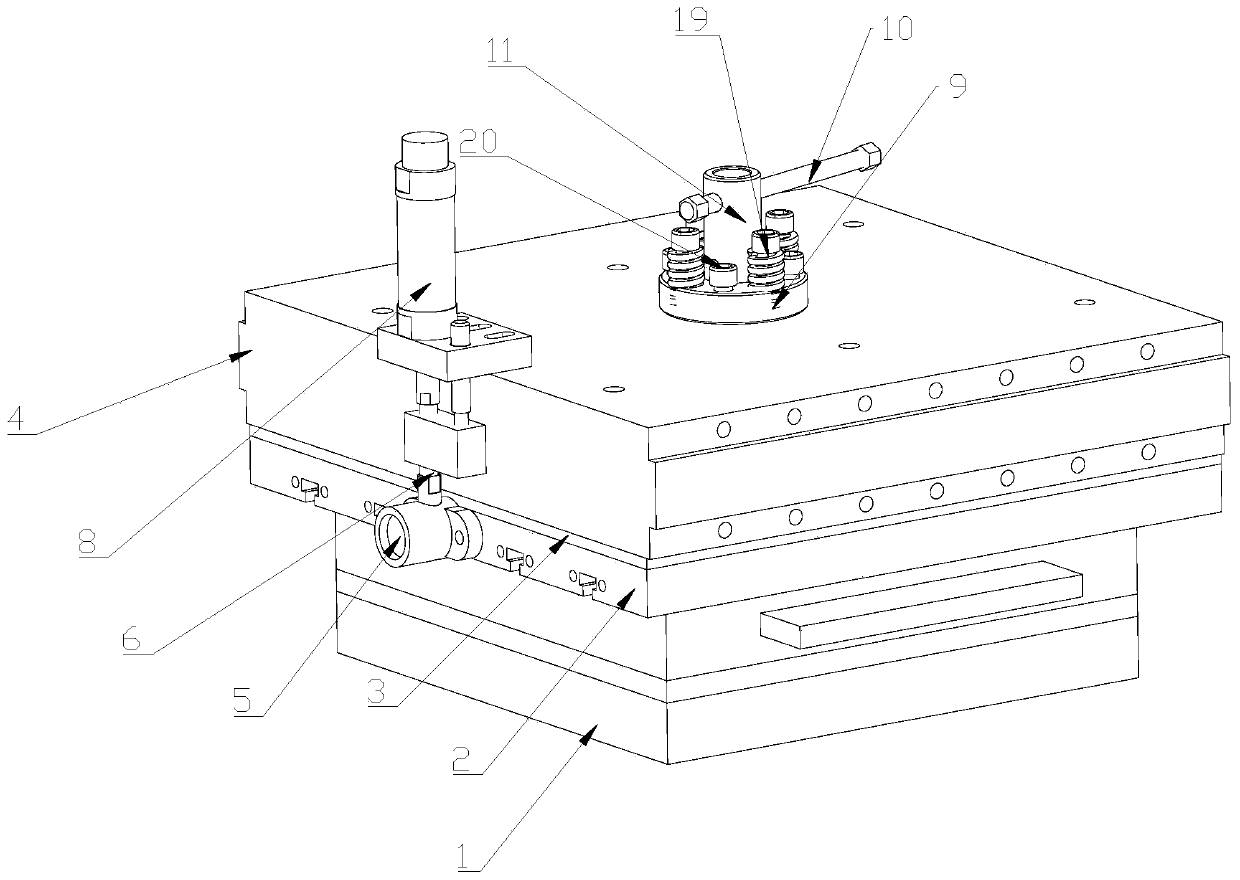

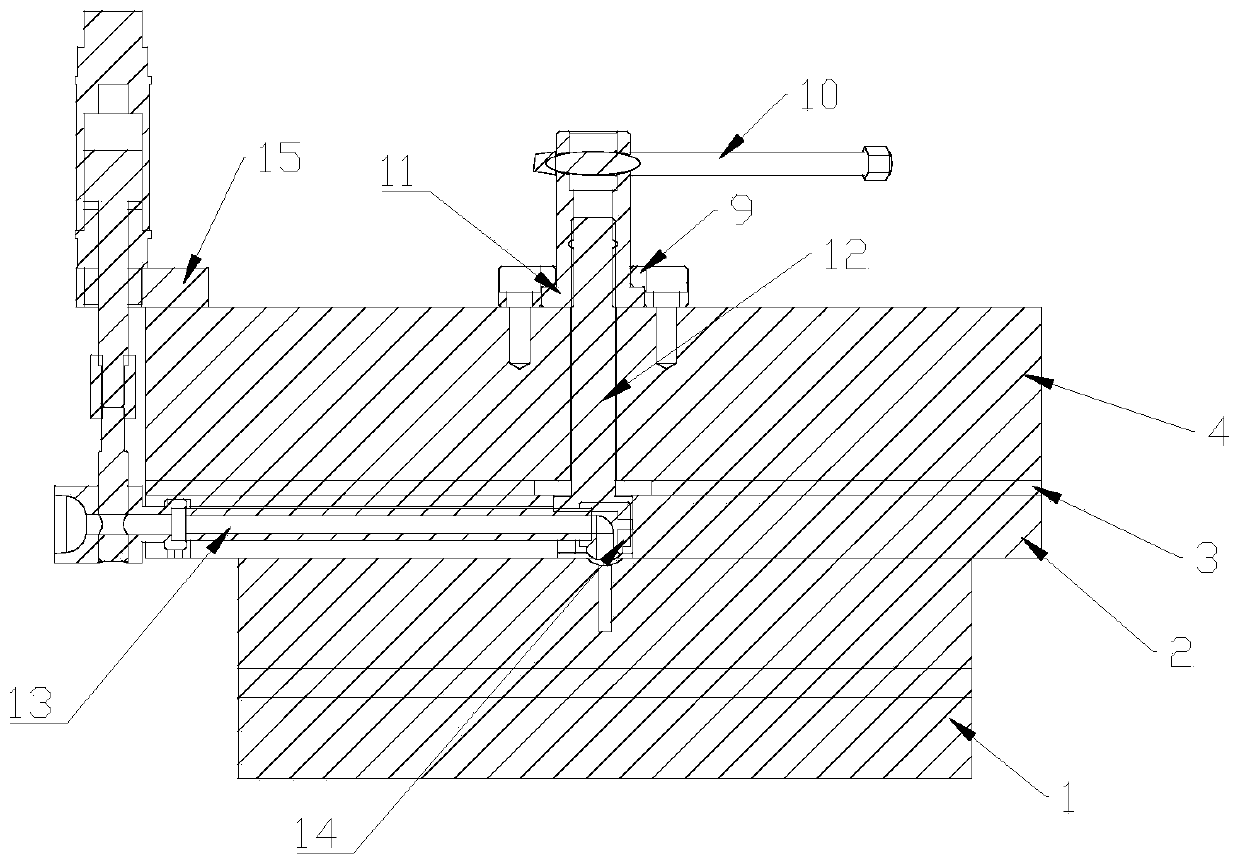

[0020] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, this embodiment provides a device that does not leak material when opening and closing the mold, including a mold 1, the top of the mold 1 is provided with a material inlet, the material inlet communicates with the mold cavity, and the mold 1 is engaged in the guide In the fixed groove 16 of the flow plate 2, an accommodating groove is provided on the side where the deflector 2 and the mold 1 are attached, and a feeding pipe 13 is installed in the accommodating groove, and the feeding pipe 13 feeds The end is fixedly connected to the injection nozzle 5, and the injection nozzle is installed on one side of the deflector 2, and the discharge end of the feeding pipe 13 is fixedly connected to the inlet end 17 of the mold nozzle 14, and the inlet port 17 of the mold inlet The outlet end 18 of the material nozzle 14 corresponds to the feed port on the top of the mold 1 and the outlet end 18 communicates with...

Embodiment 2

[0024] Based on Example 1, such as figure 1 As shown, a heat shield 3 is arranged between the deflector 2 and the upper top cover 4, and the heat shield 3 is fixed on the top of the deflector 2 by screws. When the injection nozzle 5 is injected into the material, it will A large amount of heat will be brought in, which will affect the normal operation of the elements on the upper top cover 4. Then, a heat insulating plate 3 can be arranged between the deflector 2 and the upper top cover 4, so that the heat of the deflector 2 can be insulated and the heat can be prevented. Passed from deflector 2 to upper top cover 4.

Embodiment 3

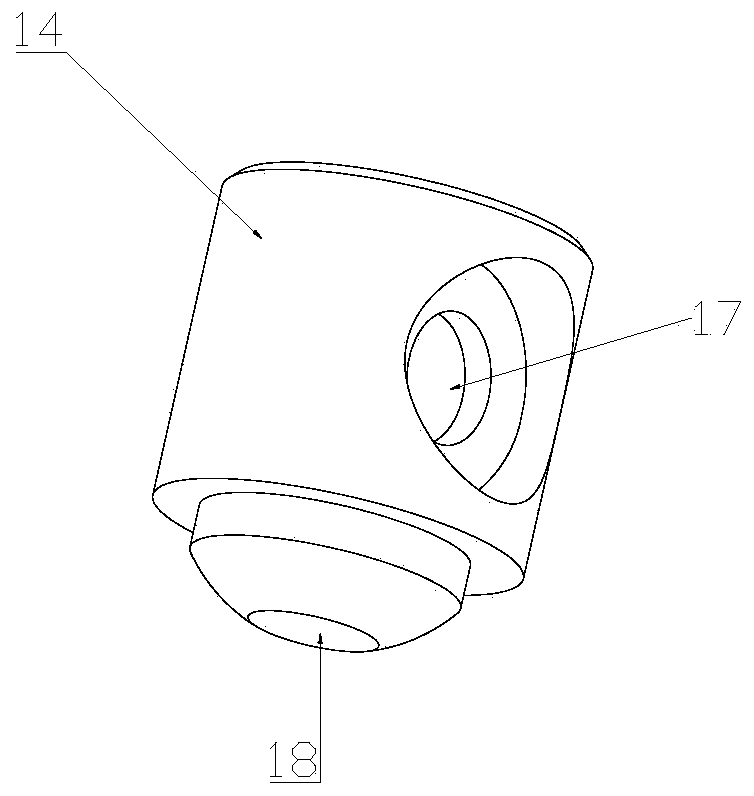

[0026] Based on Example 1, such as image 3 As shown, the inlet end 17 and the outlet end 18 of the mold-injecting nozzle 14 are at a certain angle, and can be elbow-shaped or planar. At a certain angle, the impact force of the material injected from the feeding pipe 13 can be buffered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com