A device for manually covering decorative veneers for wooden door processing

A veneer, wooden door technology, applied in wood processing appliances, adhesive application devices, manufacturing tools, etc., can solve the problems of glue blocking, inability to fully cover, low efficiency, etc., to reduce frequent glue blocking, reduce glue overflow, and quantitative The effect of evenly dripping glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

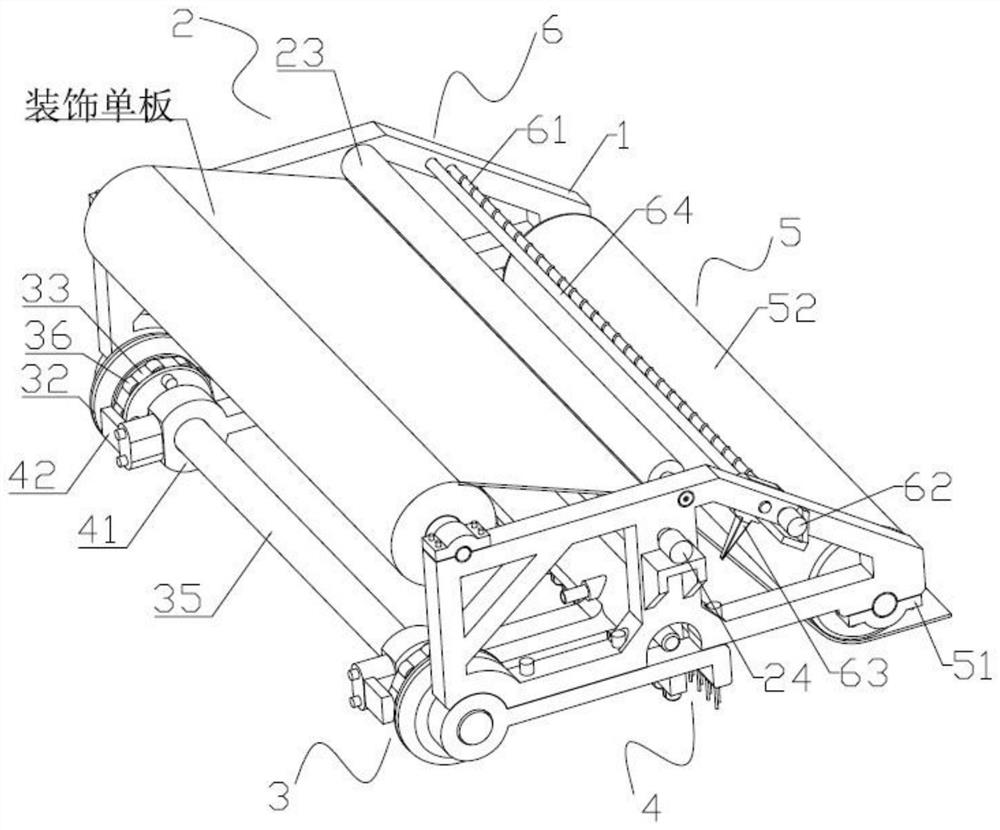

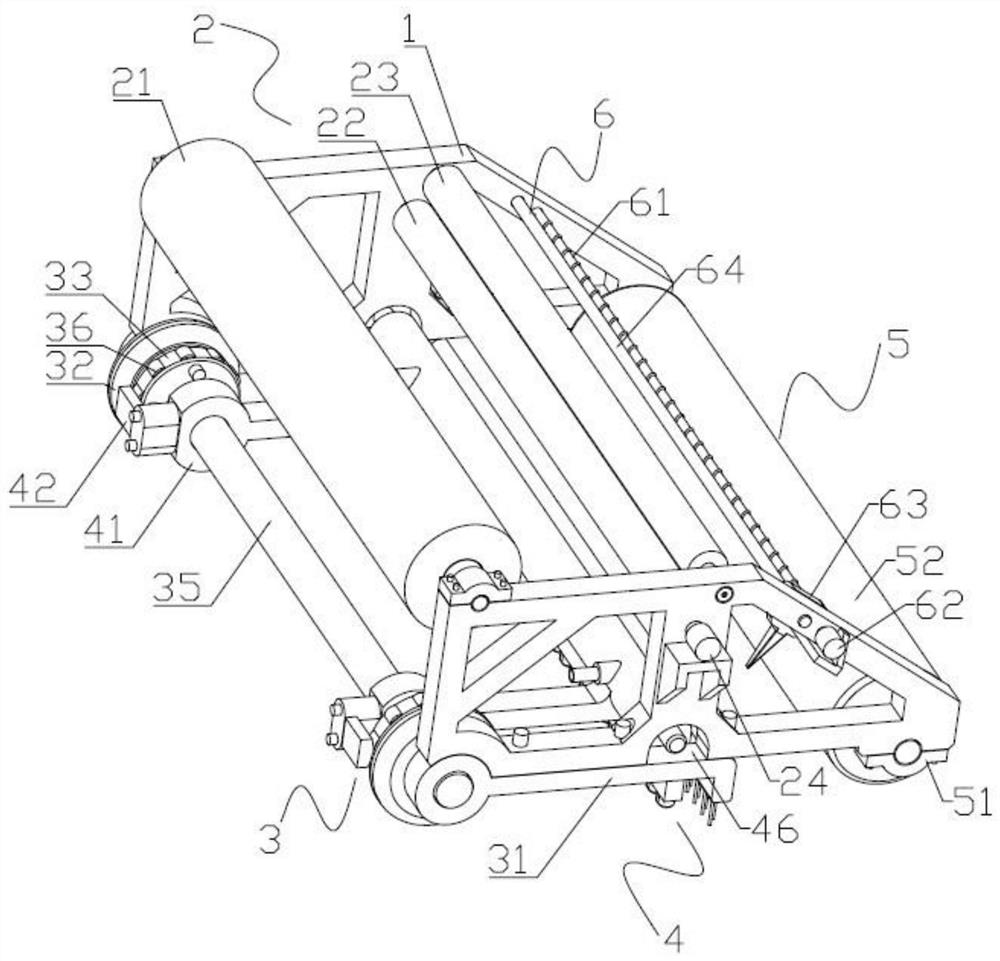

[0022] Such as Figure 1 to Figure 8 As shown, a device for manually covering decorative veneers for wooden door processing includes a frame 1, and the frame 1 is provided with a feeding assembly 2 for feeding decorative veneers with a certain temperature. The frame 1 starts from the left To the right, there are also installed a driving assembly 3 that drives the whole device to move and has an adaptive wooden door surface unevenness, a vibration and anti-blocking glue brushing assembly 4 for brushing the wooden door, and a covering assembly 5 for covering the decorative veneer.

[0023] In this embodiment, the feeding assembly 2 includes a feeding roller 21 installed on the frame 1, a regulating roller 22 and a heating roller 23, and the roller g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com