A hydrometallurgical iron removal equipment and method

A technology of hydrometallurgy and equipment, applied in the field of iron removal equipment for hydrometallurgy, can solve problems such as difficult sedimentation and filtration, lower iron removal efficiency, and complicated operation, so as to improve iron removal efficiency, improve filtration efficiency, and facilitate filtration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

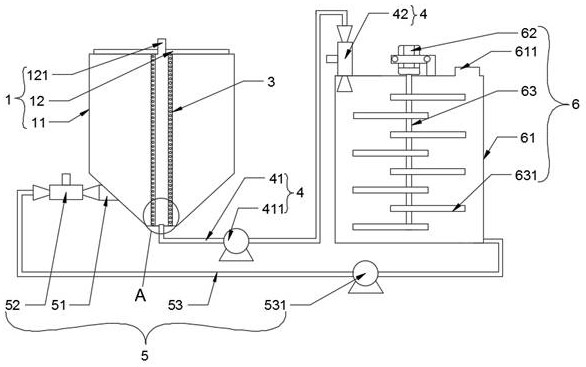

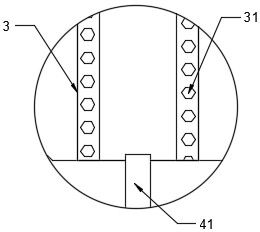

[0044] See Figure 1 ~ 2 , A wet metallurgical refrigeration apparatus includes a stirring device 6, further comprising a filter tub 1, a filtram 1 is provided with a vent 121 for balancing the air pressure in which itself, and a filter tube 3 is provided with a filter tube 3, a filter bucket. 1 The bottom of the cone is a cone bottom, and the filter tube 3 is provided with a flow outflow device 4 in communication with the stirring device 6, and a flow arrangement 5 communicating with the stirring device 6 is provided at the cone bottom of the filter tub.

[0045]As a preferred manner, the outflow device 4 includes a water pipe 1 41 in communication with the inner cavity of the filter tube 3, and the water pipe 1 41 extends an irregular portion 42, and the jet 1 42 is in communication with the stirring device 6, and the water pipe is 41 A pump one 411 is provided.

[0046] As a preferred mode, the flowing device 5 includes an inlet pipe 51 communicating with the filter tub 1 tapere...

Embodiment 2

[0064] On the basis of the first example, the present embodiment is added to the filter tub 1, and the stirring tub is added to the ferrous ionic solution and the neutralizing agent, and the mixing liquid is stirred after temperature above 130 ° C, resulting in a mixed liquid.

[0065] Specifically, the diameter of the filtration hole 31 is 15 um, and the needle iron mine can be effectively filtered.

[0066] Specifically, the raw material is a copper sulfate solution, a neutralizing agent is lime milk.

[0067] In the present embodiment, the calcium sulfate solution is filled in the filter tub 1, and the feedstock is transmitted to the stirring tank 61 by the water pump one 411, and then a ferrous ion is added to the filtrary 1 The solution and lime milk, the temperature rising to 100 ° C, drive the rotating shaft 63 to rotate and drive the stirred blade 631 to obtain a mixed liquid, and simultaneously open the water pump 2 531 and the water pump one 411, so that the ferrous ion ...

Embodiment 3

[0069] On the basis of the first example, the present embodiment is added to the filter tub 1, and the stirred ionic solution and neutralizing agent are added to 100 ° C, and the mixed liquid is mixed.

[0070] Specifically, the diameter of the filtration hole 31 is 26 um, and the needle iron mine can be effectively filtered.

[0071] Specifically, the raw material is a copper sulfate solution, a neutralizing agent is copper oxide.

[0072] In the present embodiment, the calcium sulfate solution is filled in the filter tub 1, and the feedstock is transmitted to the stirring tank 61 by the water pump one 411, and then a ferrous ion is added to the filtrary 1 The solution and copper oxide, the driving device 62 drives the rotating shaft 63 to rotate and stir the stirred blade 631 to obtain a mixed liquid, and the water pump 2 531 and the water pump 1 411 are obtained, so that the ferrous ion in the mixed liquid is jet 42 Inhaled air is oxidized into iron ions, further forming a refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com