Oxygen absorbing and releasing material, catalyst, exhaust gas purifying system, and exhaust gas treatment method

A catalyst and exhaust gas technology, applied in the field of oxygen absorption and release materials, can solve the problems of short honeycomb carrier length and short exhaust gas purification time, and achieve excellent NOx purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

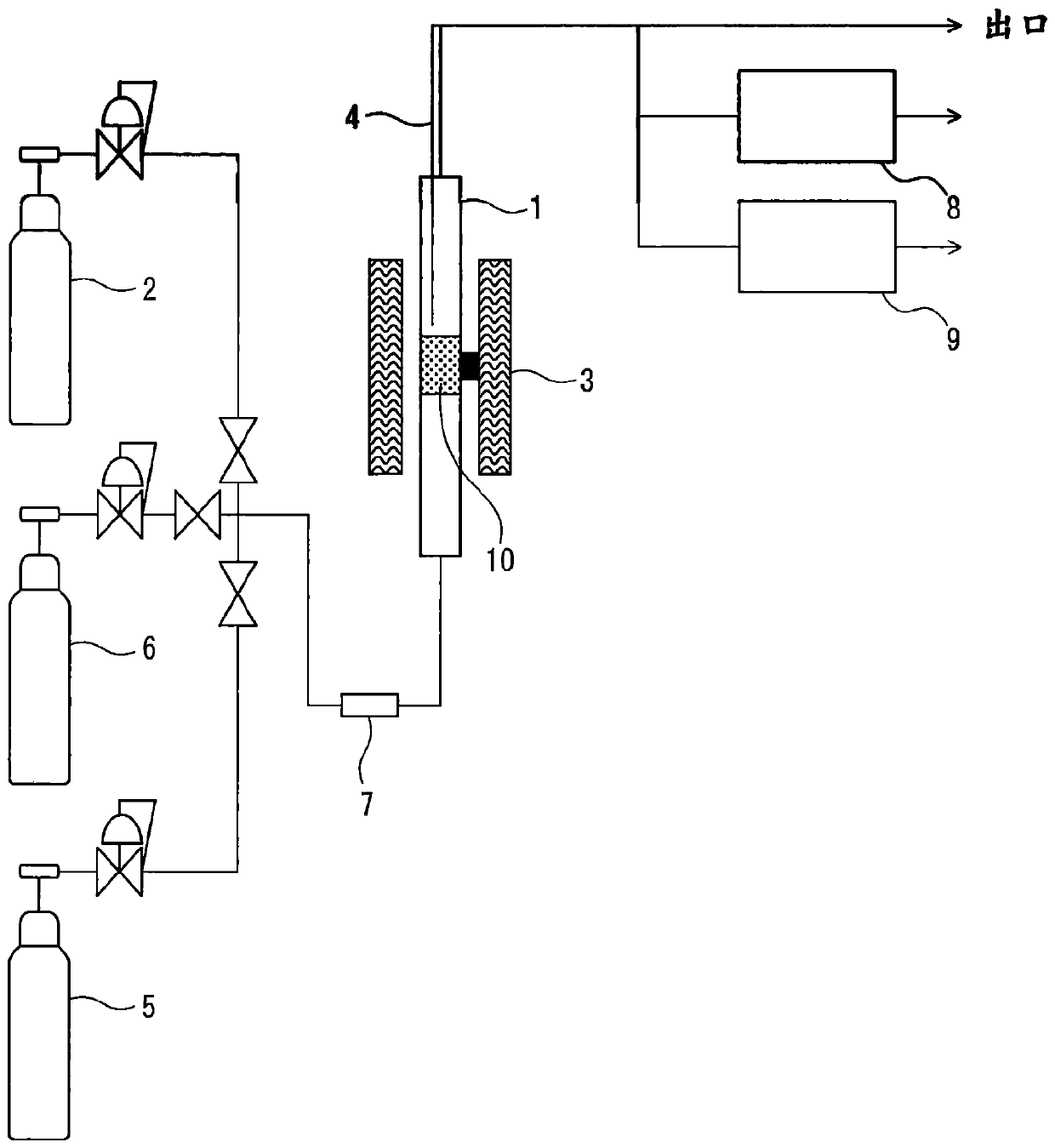

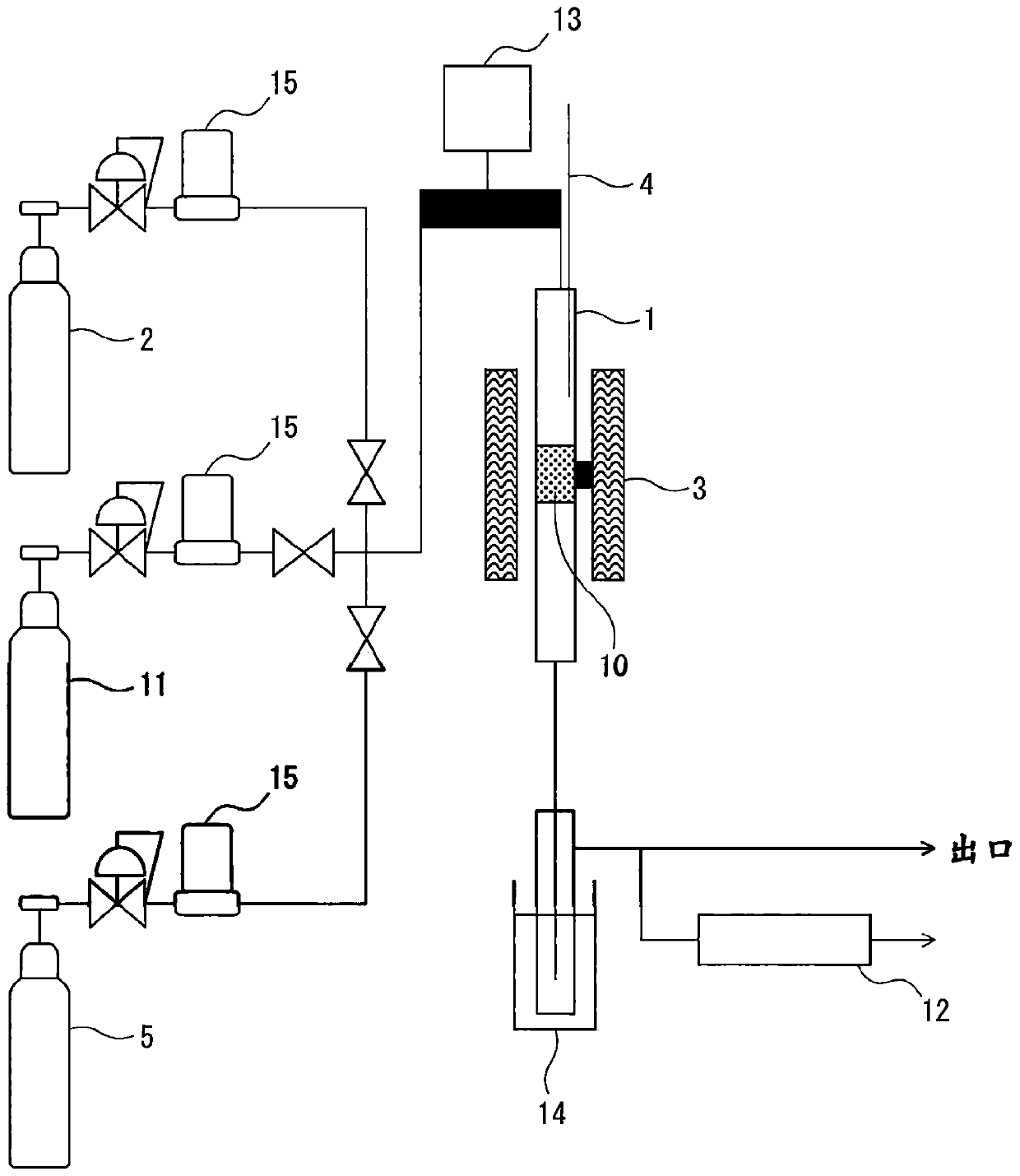

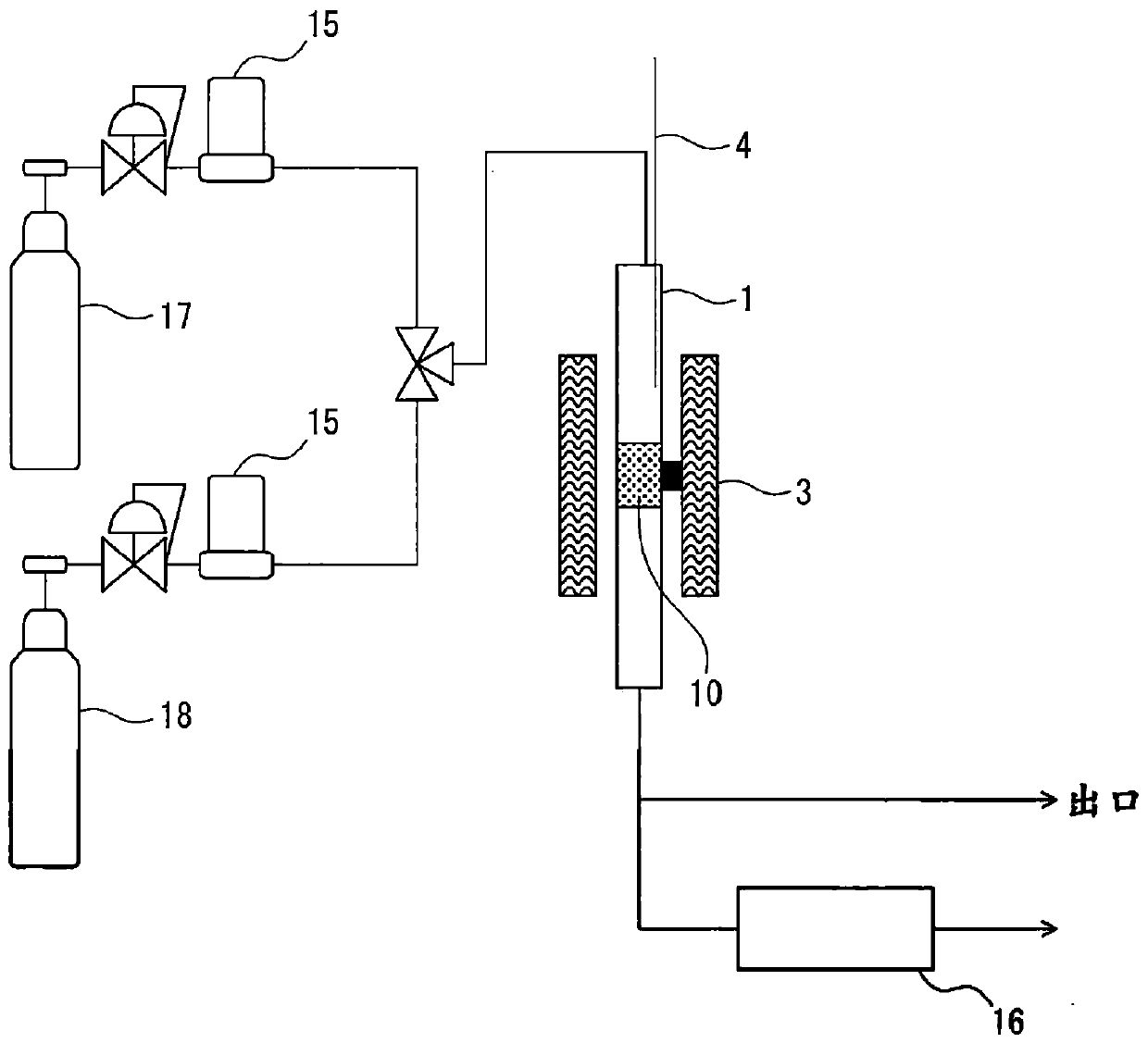

Method used

Image

Examples

Embodiment 1

[0132] Adjust the ratio of zirconium oxychloride and cerium chloride to ZrO 2 : CeO 2 =17.5:7, ZrO 2 +CeO 2 Ammonium peroxodisulfate was added to an aqueous solution having a concentration of 40.8 g / L so as to be 15 g / L. While stirring the solution, the temperature was raised to 98° C. to cause precipitation of cerium / zirconium composite sulfate. The resulting solution was poured into 3.3% ammonia water so that the pH would be 8 or higher. The resulting precipitate was repeatedly filtered and washed five times with 2.5% ammonia water to obtain a cerium / zirconium composite hydroxide filter cake.

[0133] Add pure water to the obtained cerium / zirconium composite hydroxide filter cake to prepare ZrO 2 +CeO 2 A slurry with a concentration of 97g / L. Hydrochloric acid was added so that the pH of the slurry might become 6.5. Add cerium chloride solution, yttrium chloride solution, praseodymium chloride solution, gadolinium chloride solution to the obtained slurry to make mass...

Embodiment 2

[0137] As shown in Table 2, the compound composition is CeO 2 : ZrO2 : Y 2 o 3 : Pr 6 o 11 :Gd 2 o 3 =45:45:5:2.5:2.5 Except that, it carried out similarly to Example 1, and obtained the ceria / zirconia type composite oxide powder.

[0138] The obtained powder was measured for ion conductivity, OSC speed, and OSC amount in the same manner as in Example 1, and the results were 4.79×10 -5 S / cm, Δt 50 is 20.0 seconds, and the amount of OSC is 480 μmol-O 2 / g.

Embodiment 3

[0140] As shown in Table 2, the compound composition is CeO 2 : ZrO 2 : Y 2 o 3 :Gd 2 o 3 =45:45:5:5 Except that, it carried out similarly to Example 1, and obtained the ceria / zirconia type composite oxide powder.

[0141] The ion conductivity of the obtained powder was measured in the same manner as in Example 1, and the result was 4.3×10 -5 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com