Preparation method of lithium secondary battery

A lithium secondary battery and battery technology, which is applied in the direction of secondary battery, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problems of loss of charge and discharge efficiency, impact on battery rate performance, battery energy density, etc., to achieve improved stability The effect of high reliability, low production cost and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

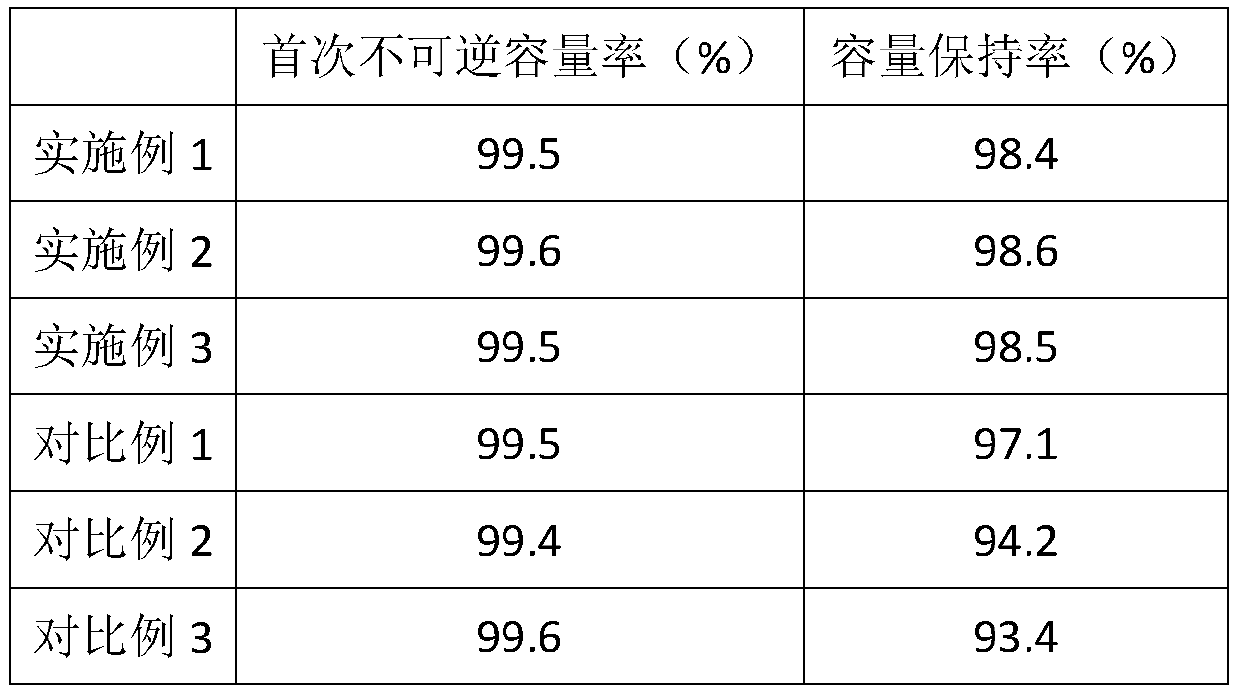

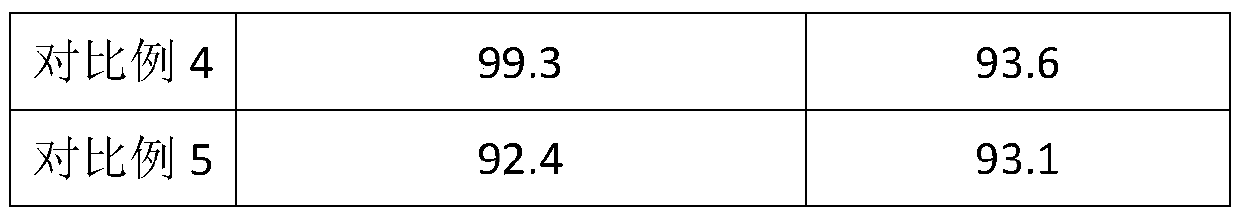

Examples

Embodiment 1

[0031] 1) Place the positive pole and the negative pole in the first electrolytic solution, the solvent in the first electrolytic solution is EC and DMC, the electrolyte lithium salt is 1mol / L lithium hexafluorophosphate, and the additive is saturated lithium carbonate and saturated sulfurous acid Lithium, wherein there are solid lithium carbonate and lithium sulfite at the bottom of the first electrolyte;

[0032] 2) Charge to 2.90V with a constant current of 0.01C;

[0033] 3) Charge to 3.45V with a constant current of 0.02C;

[0034] 4) Charge to 3.75V with a constant current of 0.05C; then charge at a constant voltage at this voltage until the charging current is lower than 0.01C;

[0035] 5) Take out the positive pole and the negative pole, assemble them with the diaphragm to form a cell and put it into the battery case;

[0036] 6) Inject the second electrolytic solution and seal the seal. The solvent in the second electrolytic solution is ethylene carbonate, diethyl c...

Embodiment 2

[0041] 1) Place the positive pole and the negative pole in the first electrolytic solution, the solvent in the first electrolytic solution is EC and DMC, the electrolyte lithium salt is 1mol / L lithium hexafluorophosphate, and the additive is saturated lithium carbonate and saturated sulfurous acid Lithium, wherein there are solid lithium carbonate and lithium sulfite at the bottom of the first electrolyte;

[0042] 2) Charge to 2.95V with a constant current of 0.02C;

[0043] 3) Charge to 3.50V with a constant current of 0.05C;

[0044] 4) Use a constant current of 0.1C to charge to 3.80V; then charge at a constant voltage at this voltage until the charging current is lower than 0.01C;

[0045] 5) Take out the positive pole and the negative pole, assemble them with the diaphragm to form a cell and put it into the battery case;

[0046] 6) Inject the second electrolytic solution and seal the seal. The solvent in the second electrolytic solution is ethylene carbonate, diethyl ...

Embodiment 3

[0051] 1) Place the positive pole and the negative pole in the first electrolytic solution, the solvent in the first electrolytic solution is EC and DMC, the electrolyte lithium salt is 1mol / L lithium hexafluorophosphate, and the additive is saturated lithium carbonate and saturated sulfurous acid Lithium, wherein there are solid lithium carbonate and lithium sulfite at the bottom of the first electrolyte;

[0052] 2) Charge to 2.95V with a constant current of 0.02C;

[0053] 3) Charge to 3.45V with a constant current of 0.05C;

[0054] 4) Use a constant current of 0.1C to charge to 3.80V; then charge at a constant voltage at this voltage until the charging current is lower than 0.01C;

[0055] 5) Take out the positive pole and the negative pole, assemble them with the diaphragm to form a cell and put it into the battery case;

[0056] 6) Inject the second electrolytic solution and seal the seal. The solvent in the second electrolytic solution is ethylene carbonate, diethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com