High-capacity long-cycle single crystal ternary cathode material and preparation method thereof

A technology of cathode materials and elements, which is applied in the field of ternary cathode materials and its preparation, can solve problems such as capacity fading and structural instability of cathode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also relates to a preparation method of a ternary positive electrode material, comprising:

[0051] (1) Mix the lithium source, the ternary precursor and the additive A in a molar ratio Li: (Ni+Co+Mn):M=(1.05~1.10):1:(0.0001~0.005), and the mixed The material is sintered, wherein the cationic element in the additive A is denoted as M;

[0052] (2) Pulverize the material after sintering in step (1) to obtain a ternary semi-finished product;

[0053] (3) Add additive B and optional surfactant and / or stabilizer to water, stir evenly to obtain coating mixture solution;

[0054] (4) Add the ternary semi-finished product obtained in step (2) to the coating mixture solution obtained in step (3) and stir evenly, the total mass of additive B and optional surfactant and / or stabilizer is three 0.05% to 5% of the mass of the semi-finished product, filtered, dried, and then sintered and crushed to obtain the final product.

[0055] The mixing in step (1) can...

Embodiment 1

[0072] In this embodiment, the ternary positive electrode material is prepared through the following steps:

[0073] (1) Will Li 2 CO 3 、Ni 0.5 co 0.2 mn 0.3 (OH) 2 and Additive A (TiO 2 ) according to the molar ratio Li: (Ni+Co+Mn):Ti=1.05:1:0.0002; mixed for 30min at a rotating speed of 500r / min, and sintered the mixed material, first heating the material to 500 ℃ for 6 hours, and then heated to 950 ℃ for calcination for 12 hours;

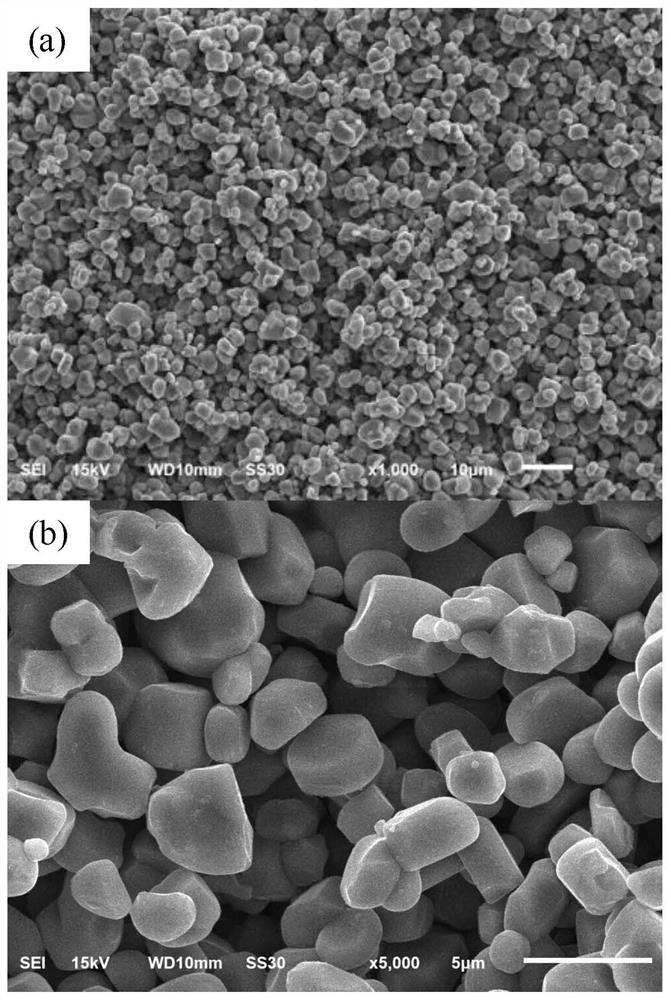

[0074] (2) Pulverize the material after sintering in the step (1), control the particle diameter of the sintered material during pulverization: D min 1μm and D 50 is 5 μm, and the ternary semi-finished product is obtained;

[0075] (3) Additive B (TiO 2 ), surfactant polyacrylic acid (PAA) and stabilizer citric acid were added to water, stirred evenly, and the stirring time was 30min to obtain a coating mixture solution; wherein, the quality of water was 3 times that of additive B. The sum of the mass of surfactant and stabilizer added...

Embodiment 2

[0078] In this embodiment, the ternary positive electrode material is prepared through the following steps:

[0079] (1) LiOH·H 2 O, Ni 0.6 co 0.2 mn 0.2 (OH) 2 and Additive A (TiO 2 ) according to the molar ratio of Li: (Ni+Co+Mn):Ti=1.06:1:0.0015, mixed for 30min at a speed of 500r / min, and sintered the mixed material, first heating the material to 550 ℃ for 6 hours, and then heated to 940 ℃ for calcination for 12 hours;

[0080] (2) Pulverize the material after sintering in the step (1), control the particle diameter of the sintered material during pulverization: D min 1μm and D 50 is 5 μm, and the ternary semi-finished product is obtained;

[0081] (3) Additive B (TiO 2), surfactant polyethylene glycol (PEG) and stabilizer ammonium acetate were added to water, stirred evenly, and the stirring time was 30min to obtain a coating mixture solution; wherein, the quality of water was twice that of additive B, and the added The sum of the mass of surfactant and stabiliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com