High-specific-surface-area carbon negative electrode material modified by stable components, preparation method of carbon negative electrode material and sodium-ion battery using carbon negative electrode material

A carbon negative electrode material with a high specific surface area technology, which is applied in the direction of negative electrodes, secondary batteries, battery electrodes, etc., can solve the problems of surface carbon defects, affecting the first coulombic efficiency and cycle stability of materials, and avoid the overheating of metal oxides. Thick cladding and uneven cladding, avoiding costly and low-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of a high specific surface area carbon negative electrode material modified by a stable component. The preparation method comprises the following steps:

[0029] Step S1: Weigh graphite oxide, the mass ratio of graphite oxide to deionized water can be in the range of 1:100 to 1:1000, place graphite oxide in a plastic beaker and add deionized water in the above proportion, then place the beaker Place in an ice-water bath environment and place in an ultrasonic stirrer to stir for 0.5-6 hours. After the treatment is completed, a graphene oxide aqueous dispersion of 1 mg / mL-10 mg / mL is obtained.

[0030] Step S2: Put 80mL of the graphene aqueous dispersion with the concentration described in S1 in a 100mL hydrothermal kettle, seal the hydrothermal kettle and place it in an explosion-proof oven, and keep the hydrothermal kettle at 120-200°C Keep warm at high temperature for 4 to 24 hours. Turn off the insulation or heating functi...

no. 1 example

[0039] Step S1: Weigh 160mg of graphite oxide into a 100mL plastic beaker of a certain capacity and add 80mL of deionized water, then place the beaker in an ice-water bath environment and place it in an ultrasonic cell pulverizer for ultrasonic treatment for 2 hours, after the treatment is completed A 2 mg / mL graphene oxide aqueous dispersion was obtained.

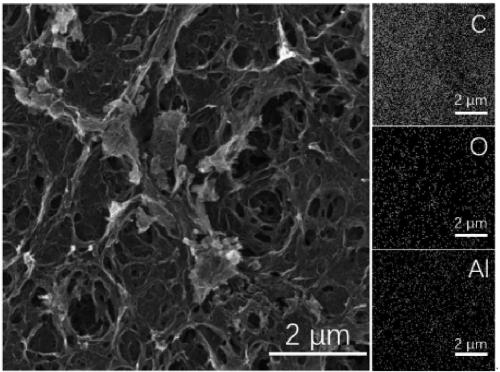

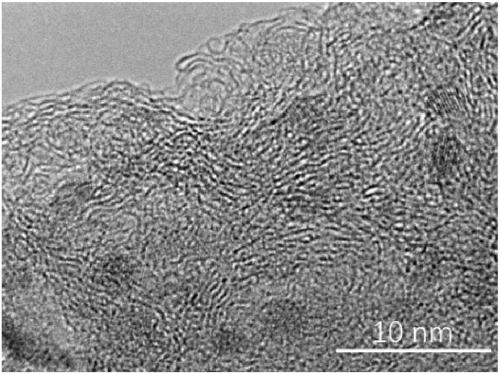

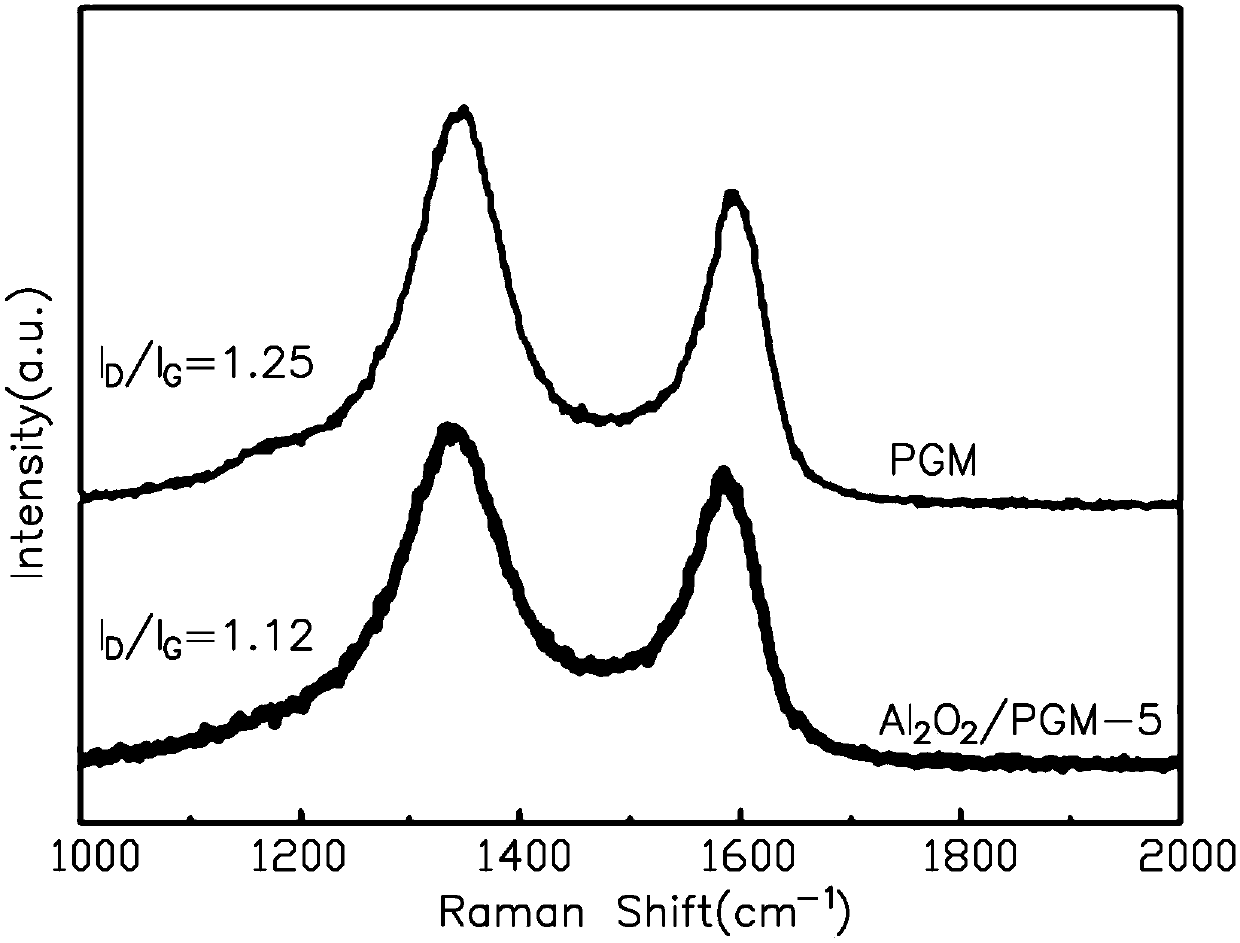

[0040] Step S2: Put 80 mL of the graphene aqueous dispersion in a 100 mL hydrothermal kettle, seal the hydrothermal kettle and place it in an explosion-proof oven, and keep the hydrothermal kettle at a temperature of 180° C. for 12 hours. Then, the graphene aqueous dispersion was cooled to room temperature with the furnace, and then it was pre-frozen with liquid nitrogen. The graphene aqueous dispersion was placed in a lyophilizer to freeze-dry for 24 hours to obtain a graphene macrobody (PGM).

[0041] Step S3: Weigh 100 mg of aluminum chloride, and place it in an aluminum oxide solution of 10 mL of absolute ethanol and ...

no. 2 example

[0045] The only difference between the second embodiment and the first embodiment is that the mass of aluminum chloride added in step S3 of the second embodiment is 1000 mg, and the temperature is kept at 160° C. for 24 hours after washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com