High-acid-resistance aluminum-plastic film for lithium battery and preparation method

A high acid-resistant, aluminum-plastic film technology, applied in the direction of lithium batteries, battery pack components, chemical instruments and methods, etc., can solve the problem of poor acid corrosion resistance of surface heat-resistant resins, surface dissolution of aluminum-plastic films, and resistance to electrolysis Liquid and other problems, to achieve good hydrofluoric acid resistance, improve puncture resistance strength, improve the effect of barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

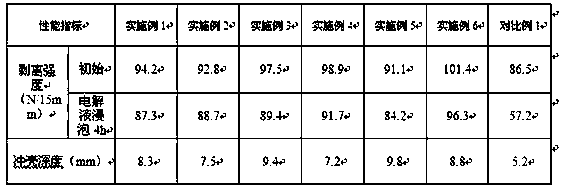

Embodiment 1

[0031](1) Add polyphenylene sulfide pure resin, terephthalate solvent, carbon fiber, heat stabilizer and antioxidant to twin-screw extruder for melting, and then cast and cool to form a film to obtain polyphenylene sulfide / Carbon fiber film; terephthalate solvent is dimethyl terephthalate; thermal stabilizer is dialkyl tin maleate; antioxidant is antioxidant 1010; the screw diameter of twin-screw extruder is 50mm , the length-diameter ratio is 32:1, and the extrusion temperature is 270 °C; in the casting cooling film formation, the temperature of the cooling roll is 3 °C;

[0032] The raw materials are calculated by mass percentage: polyphenylene sulfide pure resin 52%, terephthalate solvent 32%, carbon fiber 13%, heat stabilizer 2%, antioxidant 1%;

[0033] (2) The heat-resistant polyethylene terephthalate film and the polyphenylene sulfide / carbon fiber film obtained in step (1) are formed into a dry-type composite film online through a calendering roller to obtain a composi...

Embodiment 2

[0038] (1) Add polyphenylene sulfide pure resin, terephthalate solvent, carbon fiber, heat stabilizer and antioxidant to twin-screw extruder for melting, and then cast and cool to form a film to obtain polyphenylene sulfide / Carbon fiber film; terephthalate solvent is ethylene terephthalate; heat stabilizer is bis(maleic acid monoester) dialkyl tin; antioxidant is antioxidant 1024; twin-screw extrusion The screw diameter of the machine is 60mm, the length-diameter ratio is 38:1, and the extrusion temperature is 310°C; in the casting cooling film formation, the temperature of the cooling roller is 8°C;

[0039] The raw materials are calculated by mass percentage: polyphenylene sulfide pure resin 45%, terephthalate solvent 34%, carbon fiber 17%, heat stabilizer 2%, antioxidant 3%;

[0040] (2) The heat-resistant polyethylene terephthalate film and the polyphenylene sulfide / carbon fiber film obtained in step (1) are formed into a dry-type composite film online through a calenderi...

Embodiment 3

[0045] (1) Add polyphenylene sulfide pure resin, terephthalate solvent, carbon fiber, heat stabilizer and antioxidant to twin-screw extruder for melting, and then cast and cool to form a film to obtain polyphenylene sulfide / Carbon fiber film; terephthalate solvent is butylene terephthalate; heat stabilizer is dioctyl tin maleate; antioxidant is antioxidant 3114; the screw diameter of twin-screw extruder is 55mm, the length-diameter ratio is 35:1, and the extrusion temperature is 290°C; in the casting cooling film formation, the temperature of the cooling roll is 5°C;

[0046] The raw materials are calculated by mass percentage: polyphenylene sulfide pure resin 49%, terephthalate solvent 32%, carbon fiber 15%, heat stabilizer 2%, antioxidant 2%;

[0047] (2) The heat-resistant polyethylene terephthalate film and the polyphenylene sulfide / carbon fiber film obtained in step (1) are formed into a dry-type composite film online through a calendering roller to obtain a composite pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com