Numerical simulation method for crystal growth of Inconel 625 alloy during multi-layer multi-channel laser cladding

A laser cladding, multi-layer and multi-channel technology, used in CAD numerical modeling, instrumentation, informatics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

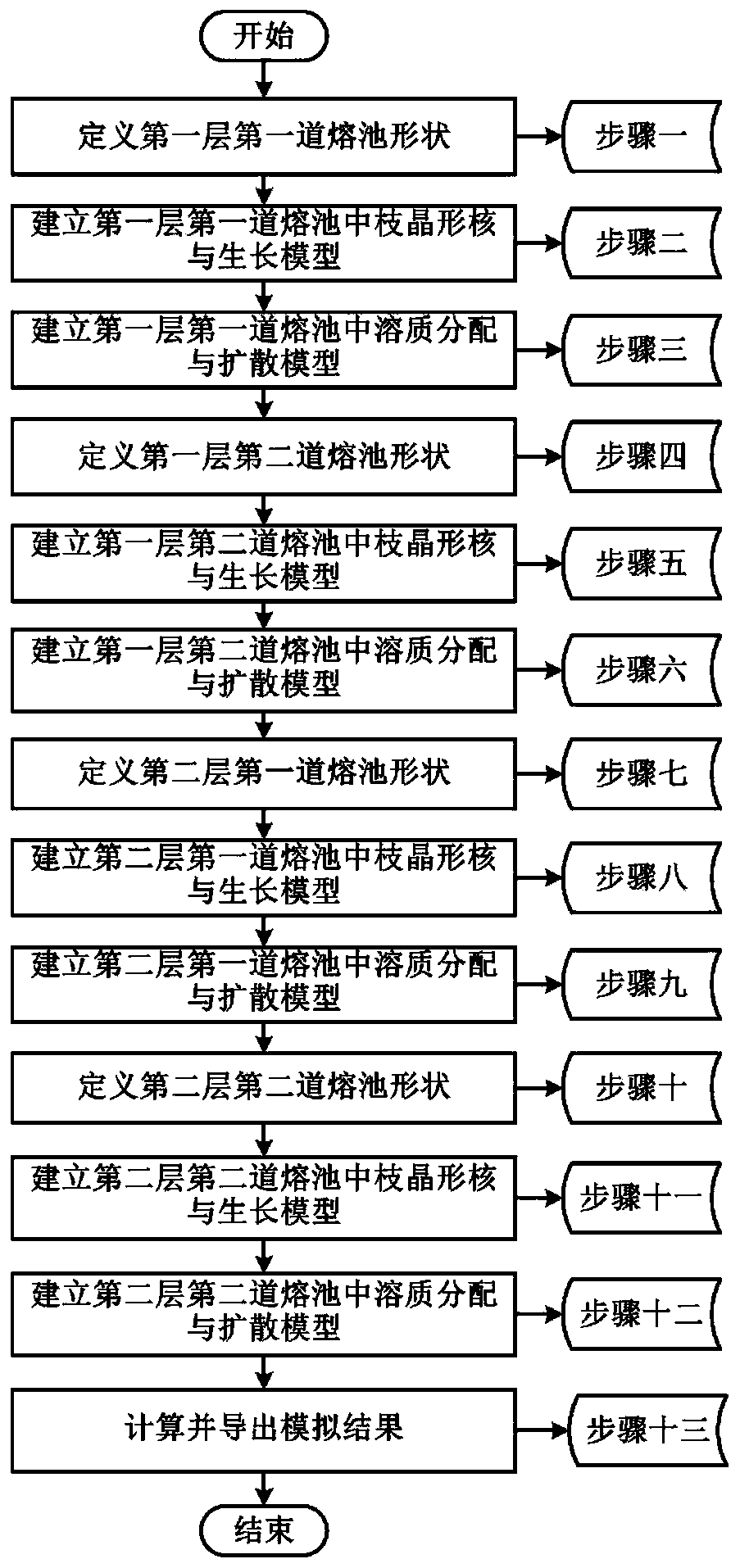

[0083] The present invention relates to a crystal growth numerical simulation method in the process of multi-layer and multi-pass laser cladding of Inconel 625 alloy, such as figure 1 As shown, the specific steps are as follows:

[0084] Step 1: Define the shape of the first molten pool in the first layer;

[0085] Step 2: Establish dendrite nucleation and growth models in the first molten pool of the first layer;

[0086] Step 3: Establish the solute distribution and diffusion model in the first melt pool of the first layer;

[0087] Step 4: Define the shape of the second molten pool in the first layer;

[0088] Step 5: Establish dendrite nucleation and growth models in the second molten pool of the first layer;

[0089] Step 6: Establish the solute distribution and diffusion model in the second melt pool of the first layer;

[0090] Step 7: Define the shape of the first molten pool in the second layer;

[0091] Step 8: Establish a dendrite nucleation and growth model in...

Embodiment 2

[0149] The present invention relates to a crystal growth numerical simulation method in the process of multi-layer and multi-pass laser cladding of Inconel 625 alloy, such as figure 1 As shown, the specific steps are as follows:

[0150] Step 1: Define the shape of the first molten pool in the first layer;

[0151] Step 2: Establish dendrite nucleation and growth models in the first molten pool of the first layer;

[0152] Step 3: Establish the solute distribution and diffusion model in the first melt pool of the first layer;

[0153] Step 4: Define the shape of the second molten pool in the first layer;

[0154] Step 5: Establish dendrite nucleation and growth models in the second molten pool of the first layer;

[0155] Step 6: Establish the solute distribution and diffusion model in the second melt pool of the first layer;

[0156] Step 7: Define the shape of the first molten pool in the second layer;

[0157] Step 8: Establish a dendrite nucleation and growth model in...

Embodiment 3

[0215] According to the crystal growth numerical simulation method in a kind of Inconel 625 alloy multi-layer multi-pass laser cladding process of the present invention, the simulation result of dendrite growth in the first laser cladding layer of the second layer of Inconel 625 alloy can be calculated, such as Figure 8 shown.

[0216] Figure 8 is the growth morphology of dendrites in the first cladding layer of the second layer when the solidification time is 0.74s, 0.85s, and 0.95s respectively. It can be seen from the figure that the crystal grains in the molten pool are coarse columnar crystals, which is caused by the overheating of the liquid metal due to the fact that the heat in the molten pool is not conducive to dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com