Fuel conveying system with drying device

A fuel delivery and drying device technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems that affect the combustion calorific value of the mixture of sludge and coal ash, and affect the power generation efficiency of thermal power plants, so as to ensure the combustion calorific value and improve drying efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

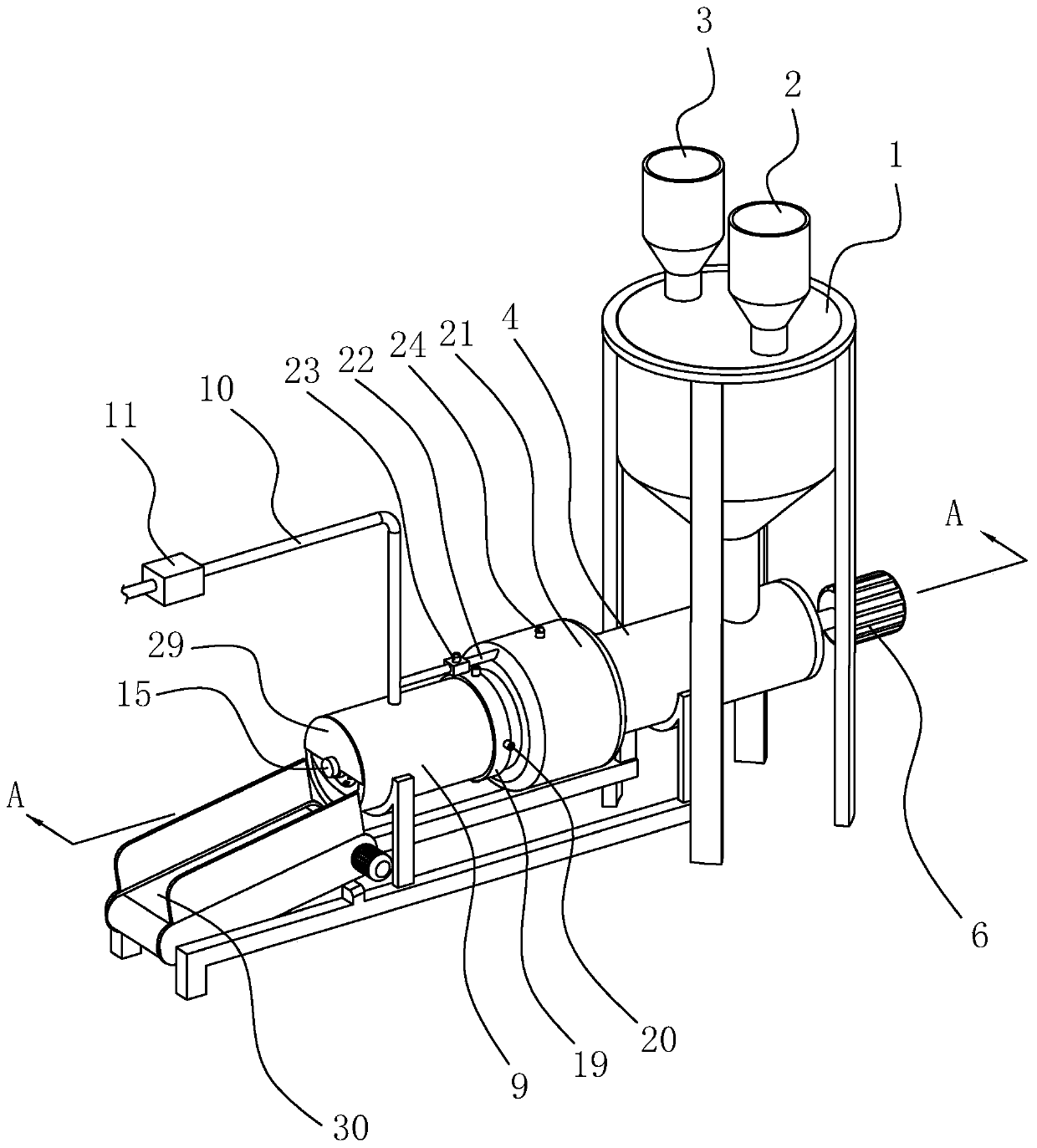

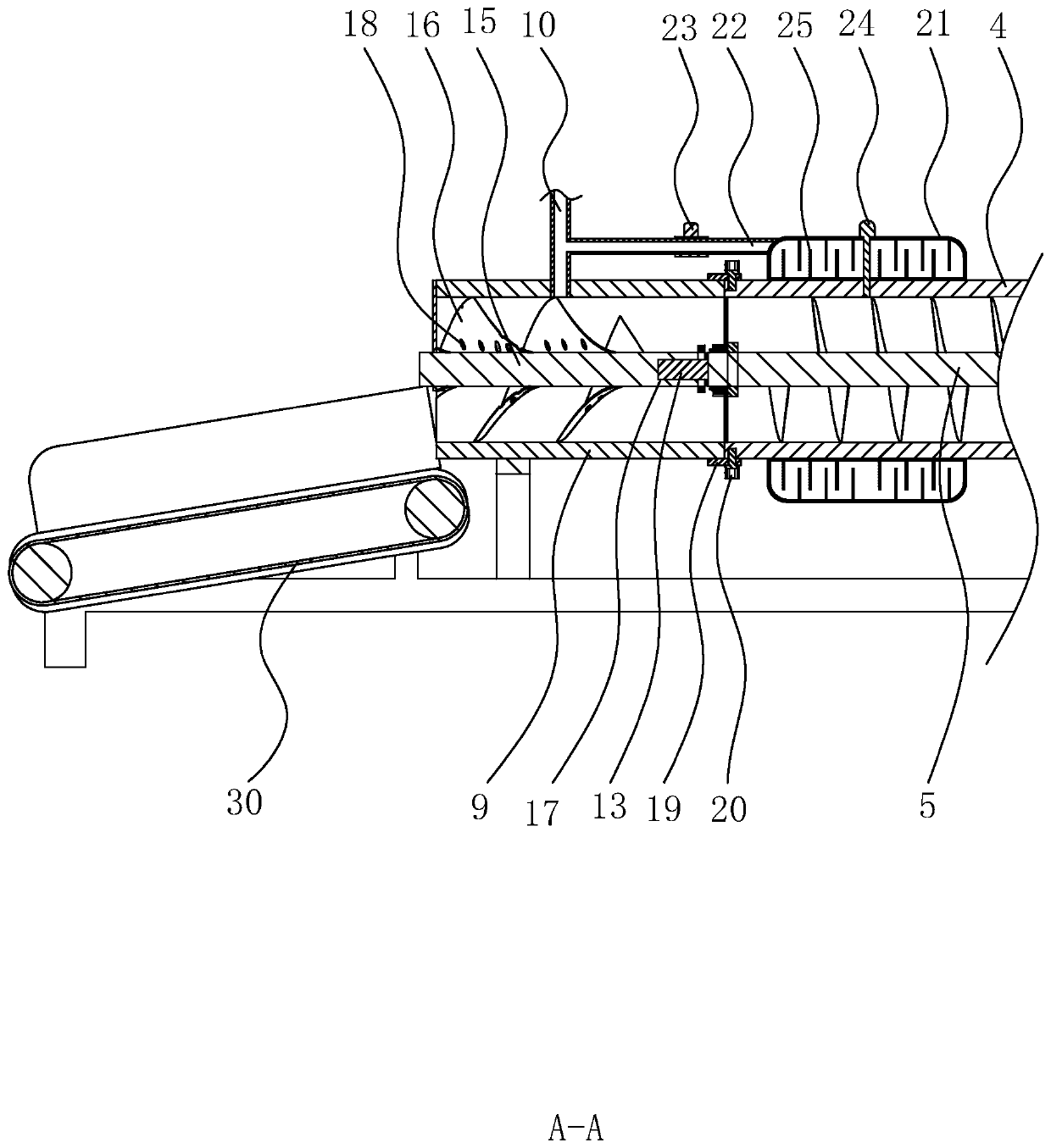

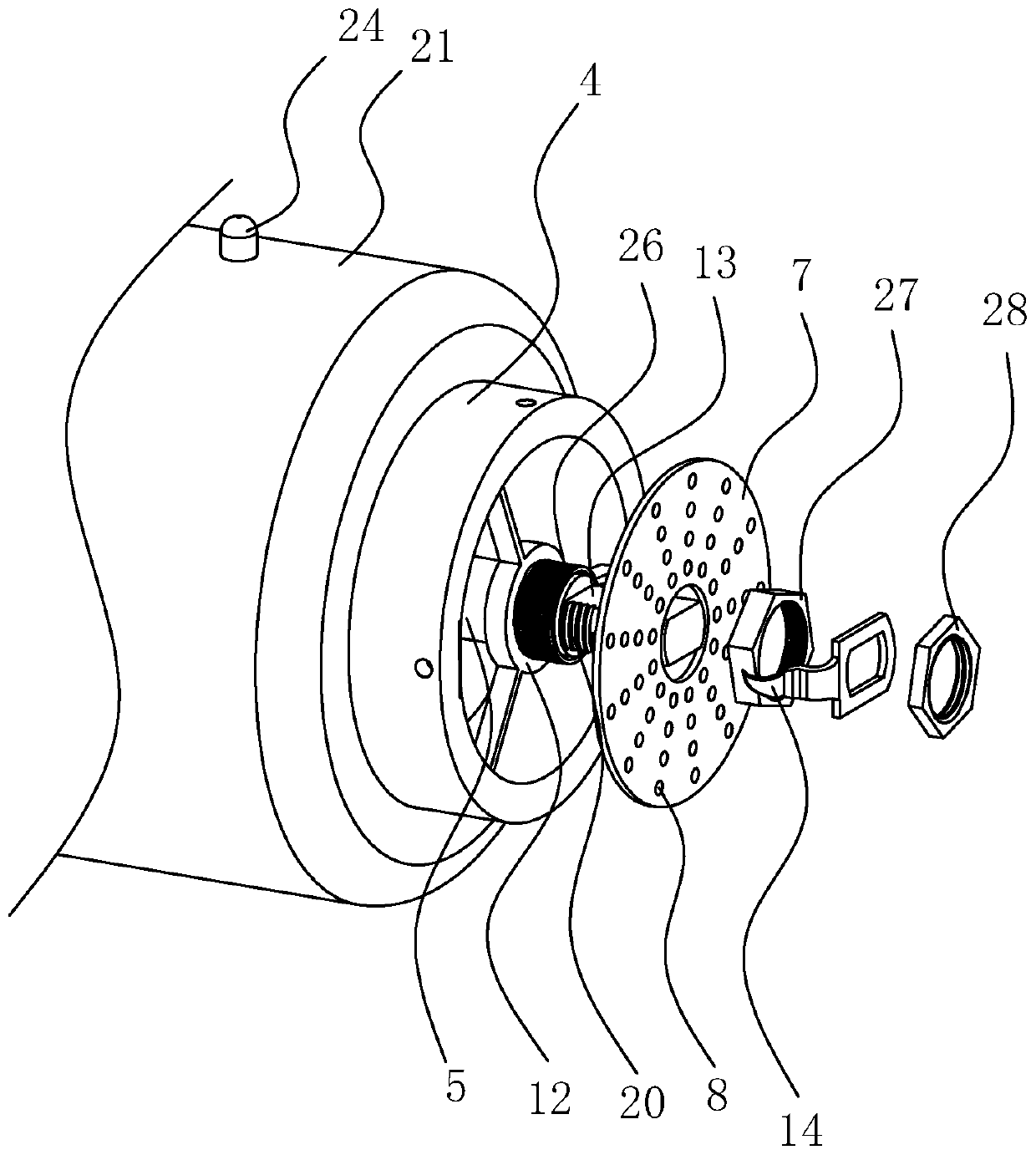

[0040] refer to figure 1 and figure 2 , is a fuel delivery system with a drying device disclosed in the present invention, including a feeding device, a mixing tank 1, a material extruding device, a drying device and a transmission device 30; the feeding device includes a container for holding pulverized coal and sludge The pulverized coal hopper 2 and the sludge hopper 3, the pulverized coal hopper 2 and the sludge hopper 3 are arranged directly above the mixing tank 1 and the outlets of both extend into the material inlet of the mixing tank 1; the extruding device includes a horizontal setting And the material cylinder 4 whose material inlet is connected with the material outlet of the mixing tank 1, the coaxial rotation in the material cylinder 4 is connected with the auger 5, the end of the material cylinder 4 close to the mixing tank 1 is closed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com