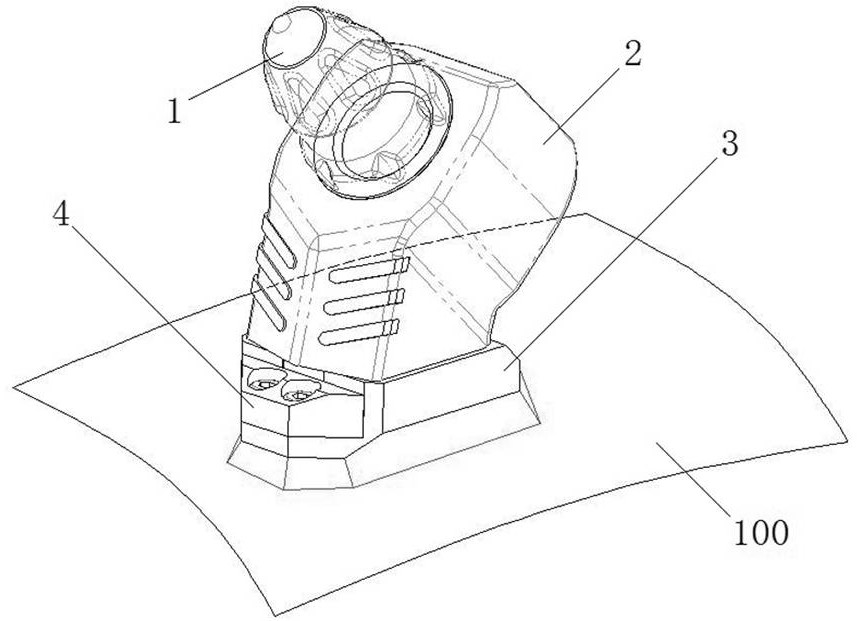

A detachable cutting tool assembly

A cutting tool and detachable technology, which is applied in the field of detachable cutting tool assembly, can solve the problems of replacement and inability to carry out gear seats, etc., and achieve the effects of preventing falling off, improving reliability, and increasing bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

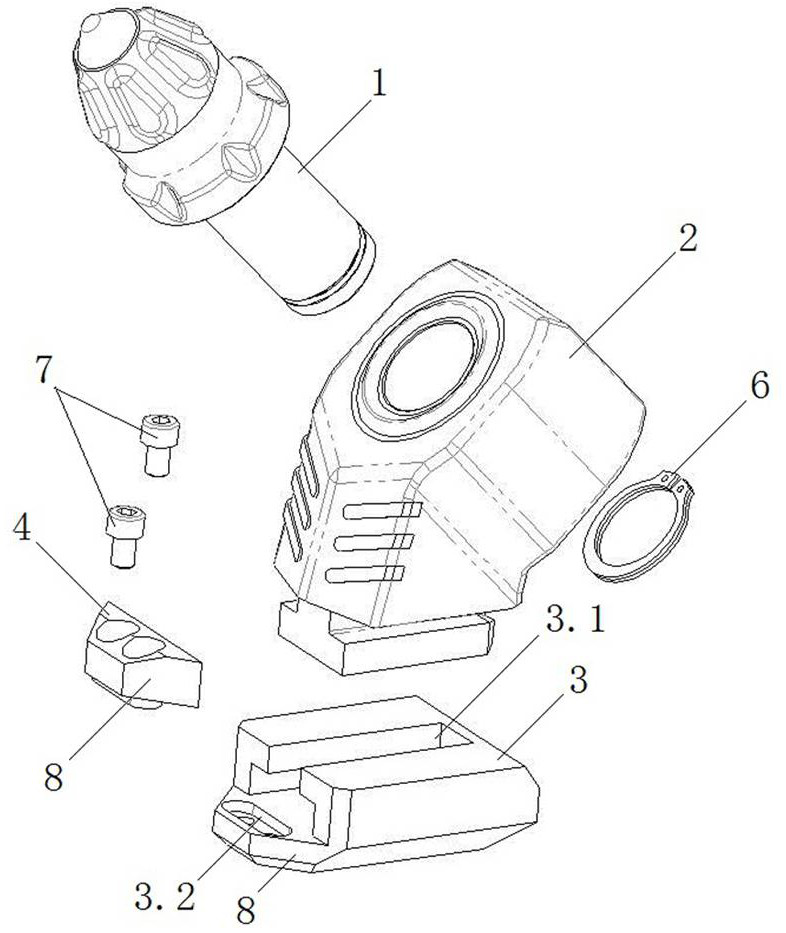

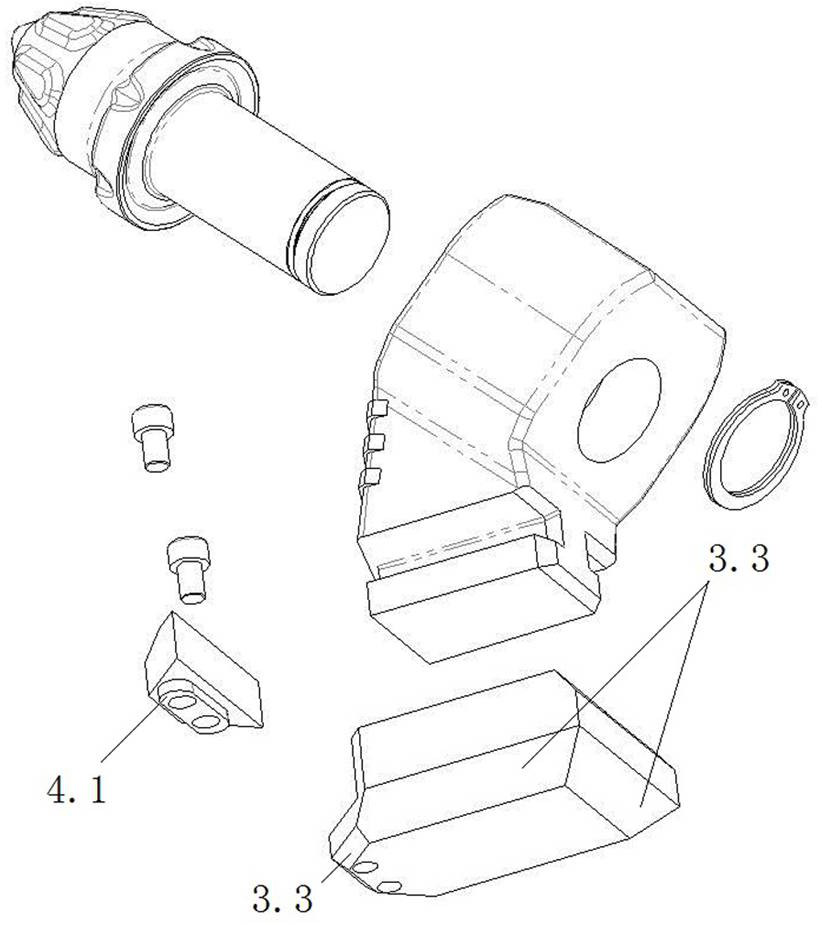

[0030] This embodiment provides a detachable cutting tool assembly, including a conical pick 1, a bevel tooth holder 2, a connecting seat 3 and a fixing block 4; the conical pick 1 includes an integrally formed tooth shank 1.1, a tooth Shoulder 1.2, toothed rod 1.3 and tapered part 1.4; toothed shank 1.1 and toothed shank 1.3 are cylindrical structures; toothed shoulder 1.2 is of circular truncated structure, the bottom surface is connected with toothed shank 1.1, and the top surface is connected to the toothed bar through annular transition surface 1.5 1.3 are connected; the conical part 1.4 is located on the gear rod 1.3, the top is brazed with cemented carbide 1.6, and a plurality of oval anti-bending beams 1.7 are evenly arranged on the circumferential surface; the oval anti-bending beam 1.7 adopts the form of small upper and lower Arrangement, the oval profile curve of oval flexural beam 1.7 is controlled by parametric equation (1),

[0031]

[0032] where c is a numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com