A sludge treatment method for alkaline treatment coupled with a single-chamber microbial electrochemical system

A technology of microbial electrochemistry and sludge treatment, applied in electrochemical sludge treatment, biological sludge treatment, sludge treatment and other directions, can solve the problem of not being able to completely decompose excess sludge, increase the concentration of organic matter and improve degradation The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Sludge treatment method of alkali treatment coupling single chamber microbial electrochemical system, the specific steps are as follows:

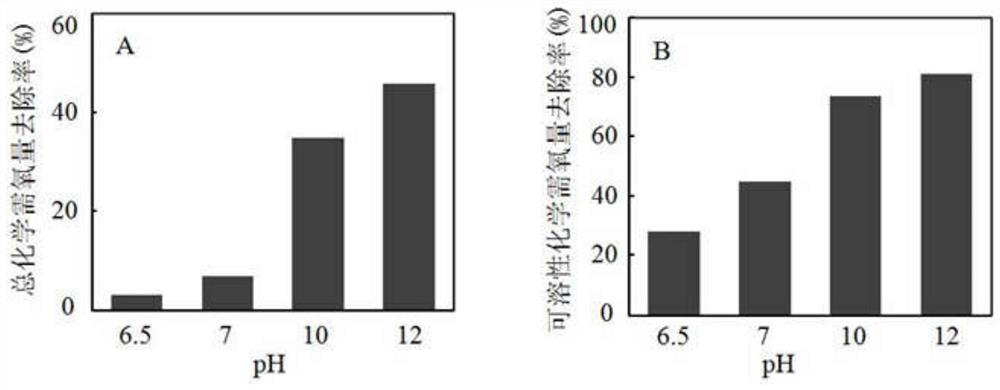

[0025] (1) Sludge alkali treatment: The residual sludge sample of the sewage treatment plant will be introduced into the base treatment tank by the alkali treatment pool. The pH is measured by the pH meter, and the pH of the original remaining sludge The value is approximately 6.5, while the agitator is constantly stirred, NaOH (2 mol / L) is added to 12 of the alkali-treated cell acid base adjustment port to adjust the pH of the remaining sludge to 12, and the preservation is stored at room temperature for 14 hours;

[0026] (2) Construction of a single-chamber microbial battery: Take the original sludge in the soda pool of the 100 mg sewage treatment plant (containing a mature growth strain), inoculated from the strain inoculation to the single-chamber microbial battery, according to the original sodium acetate The mass volume of the s...

Embodiment 2

[0030] Sludge treatment method of alkali treatment coupling single chamber microbial electrochemical system, the specific steps are as follows:

[0031] (1) Sludge alkali treatment: The residual sludge sample of the sewage treatment plant will be introduced into the base treatment tank by the alkali treatment pool. The pH is measured by the pH meter, and the pH of the original remaining sludge The value is about 6.5, while the agitator is constantly stirred, NaOH (1.5 mol / L) is added to NaOH (1.5 mol / L) by the alkali treatment tank acid base adjusted port, and the pH of the remaining sludge is adjusted to 10, and it is allowed to preserve 15 hours at room temperature;

[0032](2) Construction of a single chamber microbial battery: Take the original sludge in the sink of the sink of the sink of the sink of the Sewage Treatment Plant, inoculated into the single-chamber microbial cell from the strain inoculation, according to the original sodium acetate. The mass volume of the so...

Embodiment 3

[0036] Sludge treatment method of alkali treatment coupling single chamber microbial electrochemical system, the specific steps are as follows:

[0037] (1) Sludge alkali treatment: The residual sludge sample of the sewage treatment plant will be introduced into the base treatment tank by the alkali treatment pool. The pH is measured by the pH meter, and the pH of the original remaining sludge The value is about 6.5, while the agitator is constantly stirred, NaOH (1 mol / L) is added to 7 by alkali treatment tank acid base adjusted port, and the pH of the remaining sludge is adjusted to 7, and the preservation is stored at room temperature for 16 hours;

[0038] (2) Construction of a single chamber microbial battery: Take the original sludge in the soda pool of the 110mg sewage treatment plant (containing a mature growth strain), inoculated into the single-chamber microbial cell from the strain, according to the original sodium acetate The mass volume of the solution is 10: 1 rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com