Surface-exposure-based multi-degree-of-freedom 3D printing method, device and system

A 3D printing, degree-of-freedom technology, applied in the field of 3D printing, can solve the problems of wasting printing materials and affecting the fineness of the surface of the model, and achieve the effect of improving the quality, surface refinement, and simplifying the post-processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

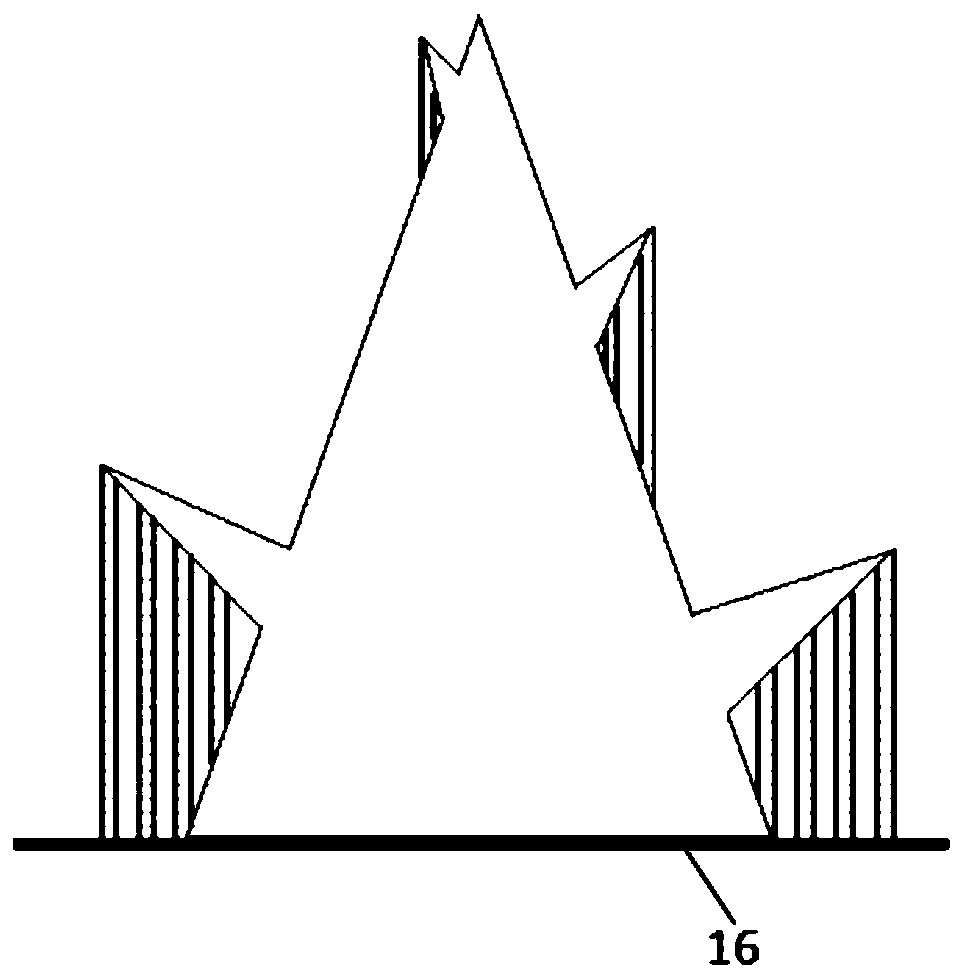

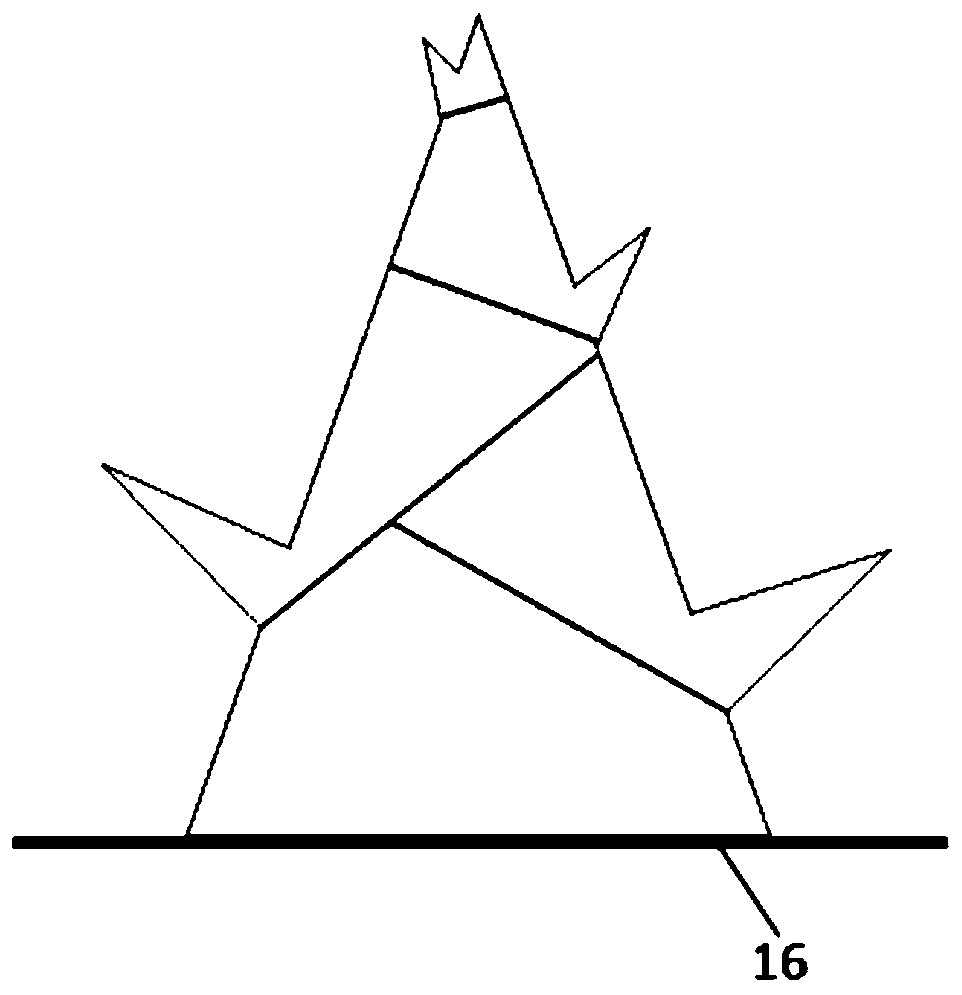

[0045] refer to image 3 , a surface exposure-based multi-degree-of-freedom 3D printing method of the present invention includes a planning step and a printing step. The planning step is used to divide several sub-models that can be printed without support according to the surface parameters of the printing model, and plan the printing path according to the sub-models. The printing step completes 3D printing according to the printing path obtained in the planning step.

[0046] The planning steps specifically include:

[0047] S1. Load the print model to obtain the triangular patches and their normal vectors on the surface of the print model. Specifically, the loaded pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com