Pulverizer for shoots of phyllostachys praecox

A milling machine and bamboo shoot technology, which is applied in the field of milling devices, can solve the problems of low production efficiency of thunder bamboo shoot milling and achieve the effect of improving milling efficiency and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

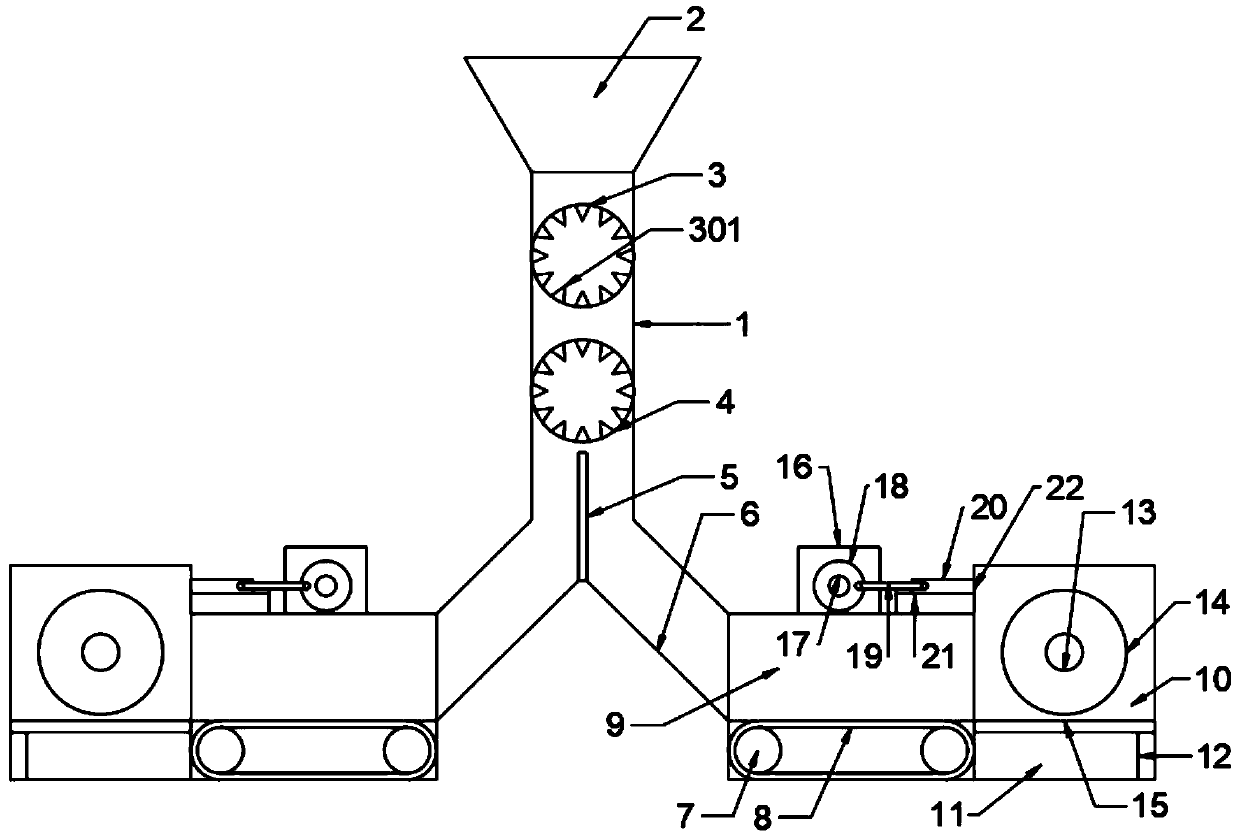

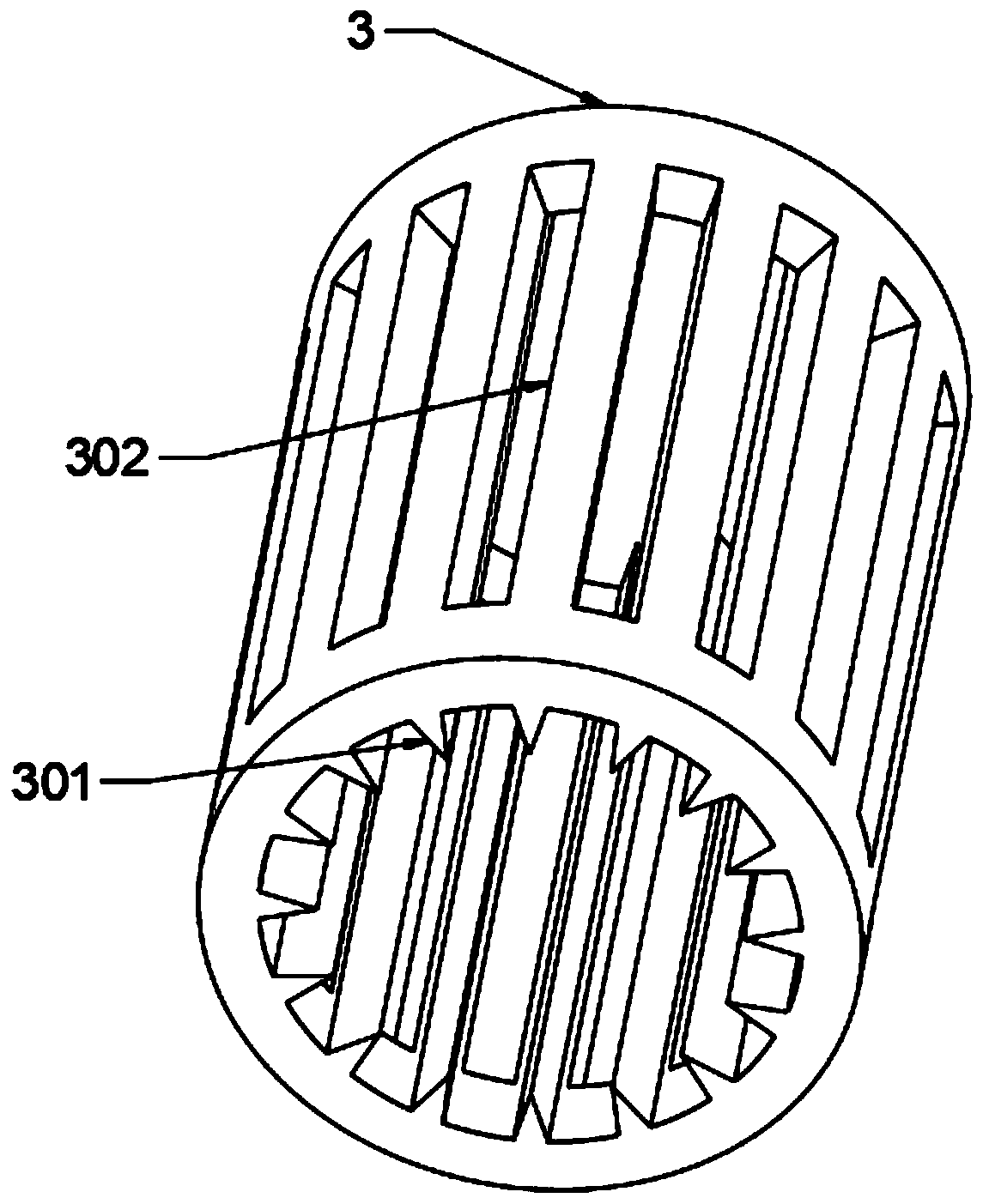

[0022] see Figure 1~3 , in the embodiment of the present invention, a thunder bamboo shoot mill comprises a housing 1 and a material inlet 2, the material inlet 2 is arranged on the top of the housing 1, and a first crushing device is installed directly below the material inlet 2 for rotation. The screening part 3, the second screening part 4 is rotated below the first screening part 3, the first screening part 3 and the second screening part 4 are in the shape of a circular column and contact the side wall of the connecting shell 1 in the horizontal direction Setting, the inner walls of the first crushing and screening parts 3 and the second screening and crushing parts 4 are equipped with crushing teeth 301 and the side walls are located between the two crushing teeth 301 and are provided with screening holes 302, the side walls of the first crushing and screening parts 3 The screening hole 302 opening diameter is larger than the screening hole 302 opened on the side wall o...

Embodiment 2

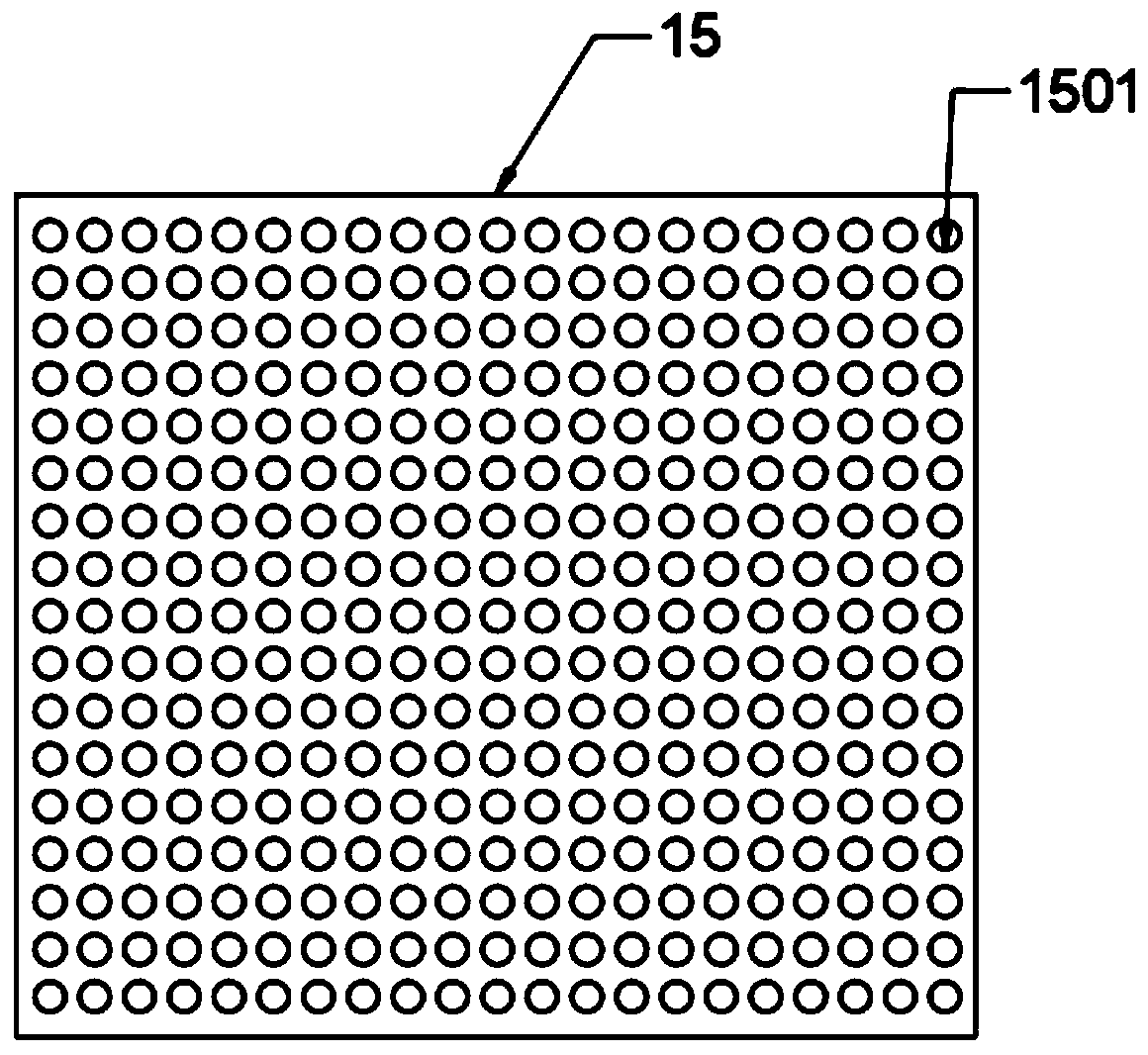

[0030]This embodiment is another embodiment of embodiment 1, and the specific structure of the moving assembly is not limited. In this embodiment, preferably, the moving assembly includes a cylinder, and the output end of the cylinder is fixedly connected to the sliding block 20; by moving The assembly includes a cylinder, the output end of the cylinder is fixedly connected with the sliding block 20, and the cylinder drives the sliding block 20 to move left and right, so that the grinding disc 14 moves left and right, and the bamboo shoots on the sieve plate 15 top are polished.

[0031] The working principle of the present invention is: the left and right sides of the baffle plate 5 are symmetrically provided with a downward inclined part 6, the lower end of the inclined part 6 is connected with a transmission part 9, and a transmission device is arranged below the transmission part 9, and the transmission part 9 is far away from the One end of the inclined part 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com