Visible-light-responsive iron oxide/cuprous oxide photocatalytic film and preparation method thereof

A photocatalytic film, cuprous oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the high cost and scarcity of precious metals, limited quantity, The inherent activity of the active site is poor and other problems, to achieve the effect of good photoelectric catalytic activity, high repeatability, and unfavorable peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

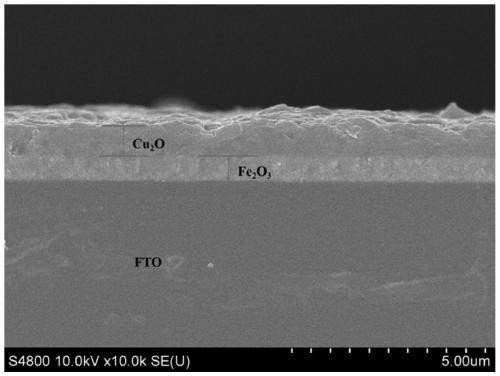

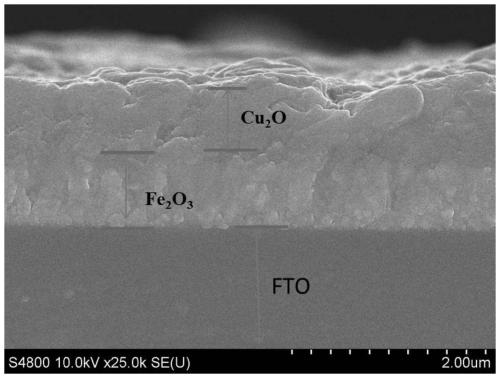

[0029] This embodiment provides a method for preparing a visible light-responsive iron oxide / cuprous oxide photocatalytic film, the specific steps are:

[0030] (1) Sonicate the FTO conductive glass in acetone, ethanol, and deionized water respectively, dry them in air, and perform electroetching in 0.1M ammonia water with a voltage of 8V and a time of 150s. Perform electro-etching pretreatment to obtain mesoporous active sites, ready for use;

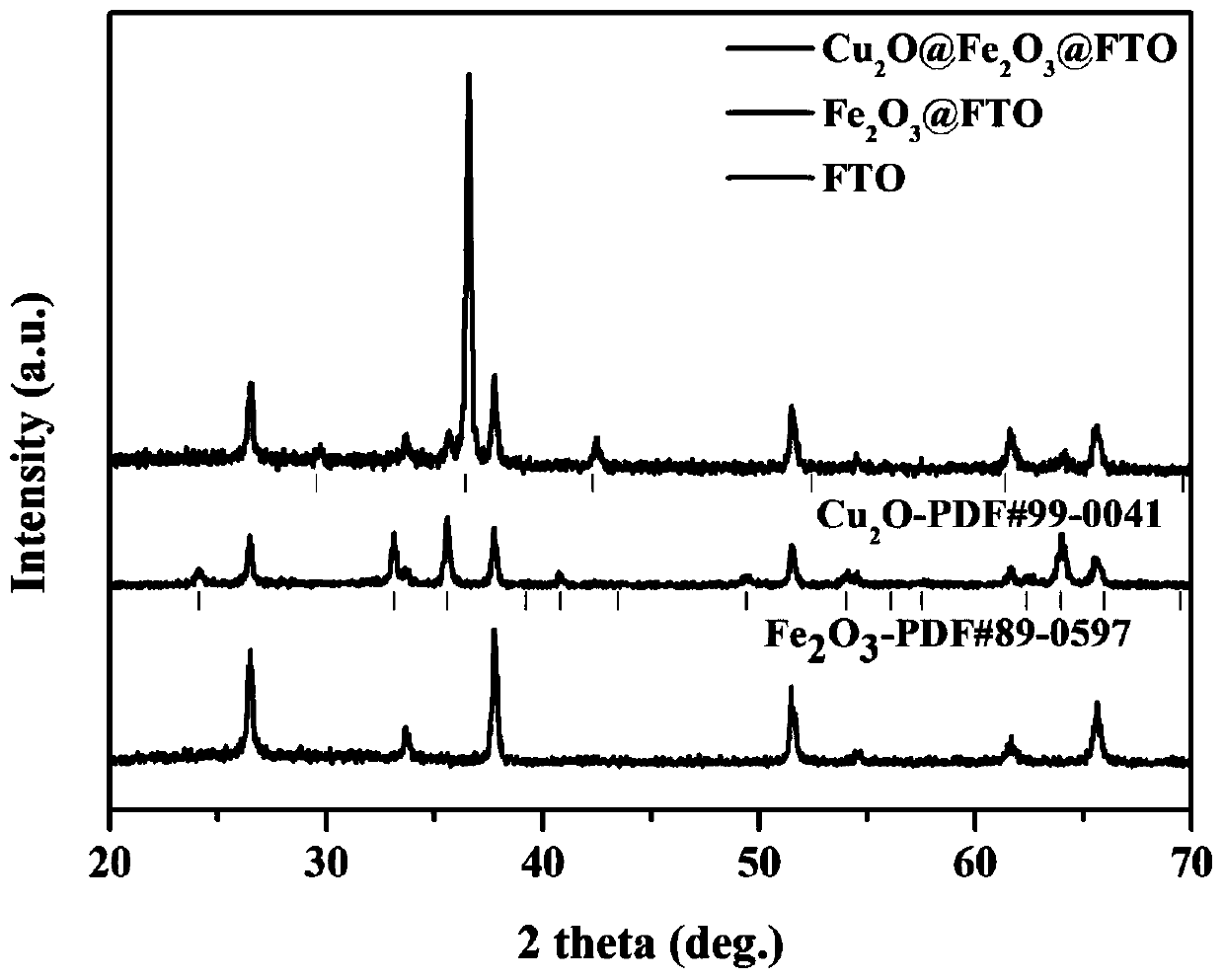

[0031] (2) Immerse the FTO conductive substrate in Fe 3+ Precursor solution, put it in a high-pressure reactor for hydrothermal film-forming reaction, the hydrothermal reaction time is 15h, and the reaction temperature is 120°C. After the reaction, the conductive substrate is washed with deionized water and dried. Put it into a muffle furnace and calcinate at a constant temperature of 450 ° C for 2 hours to obtain Fe 2 o 3 thin film; among them, Fe 3+ The precursor solution is ferric chloride hexahydrate (FeCl 3 ·6H 2 O), the mix...

Embodiment 2

[0034] This embodiment provides a method for preparing a visible light-responsive iron oxide / cuprous oxide photocatalytic film, the specific steps are:

[0035] (1) Sonicate the FTO conductive glass in acetone, ethanol, and deionized water respectively, dry them in air, and perform electroetching in 0.1M ammonia water with a voltage of 10V and a time of 150s. Perform electro-etching pretreatment to obtain mesoporous active sites, ready for use;

[0036] (2) Immerse the FTO conductive substrate in Fe 3+ The precursor solution was placed in a high-pressure reactor for hydrothermal film-forming reaction. The hydrothermal reaction time was 12 hours and the reaction temperature was 120°C. After the reaction, the conductive substrate was washed with deionized water. After drying, put it into a muffle furnace, and calcine at a constant temperature of 500 ° C for 2 hours to obtain Fe 2 o 3 thin film; among them, Fe 3+ The precursor solution is ferric chloride hexahydrate (FeCl 3 ...

Embodiment 3

[0039] This embodiment provides a method for preparing a visible light-responsive iron oxide / cuprous oxide photocatalytic film, the specific steps are:

[0040] (1) Sonicate the FTO conductive glass in acetone, ethanol, and deionized water respectively, dry them in air, and perform electroetching in 0.1M ammonia water with a voltage of 10V and a time of 150s. Perform electro-etching pretreatment to obtain mesoporous active sites, ready for use.

[0041] (2) Immerse the FTO conductive substrate in Fe 3+ Precursor solution, put it in a high-pressure reactor for hydrothermal film-forming reaction, the hydrothermal reaction time is 12h, and the reaction temperature is 150°C. After the reaction, the conductive substrate is washed with deionized water and dried. Put it into a muffle furnace and calcinate at a constant temperature of 500 ° C for 3 hours to obtain Fe 2 o 3 thin film; among them, Fe 3+ The precursor solution is ferric chloride hexahydrate (FeCl 3 ·6H 2 O), the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com