Electrical contact assembly with groove

A technology of electrical contacts and components, applied in the direction of contact electrical connection, contact shell/screen, contact surface shape/structure, etc., can solve the problems of low yield, easy solder climbing points, etc., and achieve large charging volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

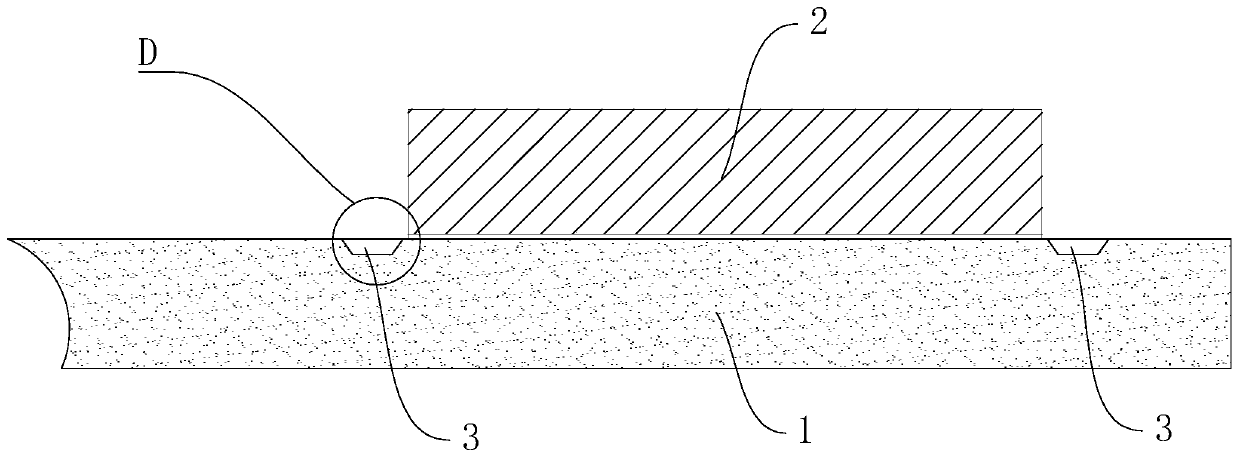

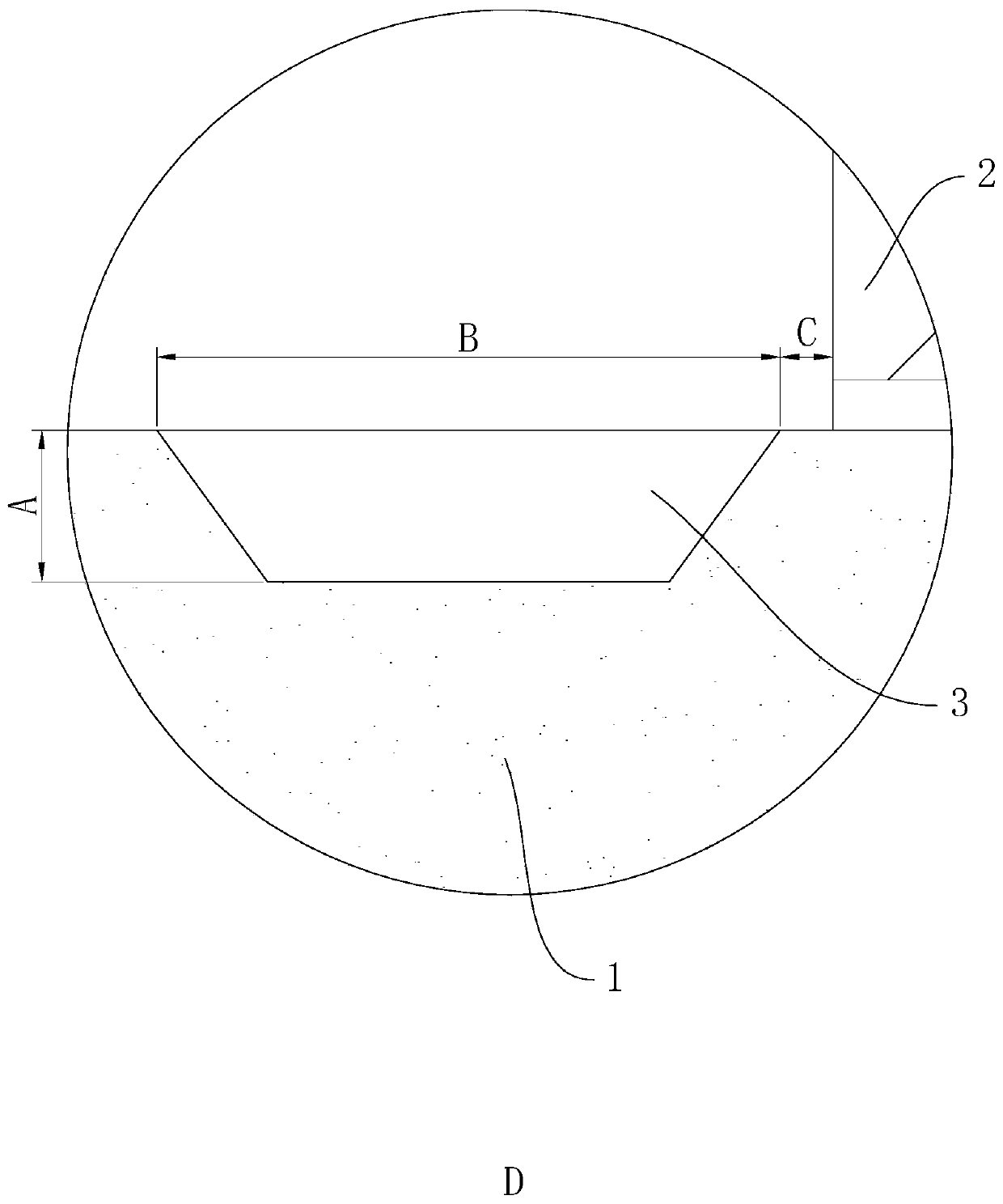

[0026] refer to Figure 1 to Figure 3 , a grooved electrical contact assembly, including a contact bridge 1 and an electrical contact 2 placed on the contact bridge 1, a groove 3 is opened on the side of the contact bridge 1 facing the electrical contact 2, and the groove 3 is arranged near the The intersection between the contact bridge 1 and the electrical contact 2; the groove 3 is arranged around the outer circumference of the electrical contact 2 to form a ring shape, and the shape of the groove 3 is adapted to the outer peripheral shape of the electrical contact 2 . The cross-sectional shape of the groove 3 includes a trapezoid, specifically an isosceles trapezoid, the lower base of the isosceles trapezoid is set upward and the inclination angle is 60°.

[0027] The distance between the groove 3 and the electrical contact 2 is 0-0.5mm, preferably 0.1mm (the letter C is used in the figure to indicate the distance between the groove 3 and the electrical contact 2); the de...

Embodiment 2

[0030] refer to Figure 4 , The difference between this embodiment and Embodiment 1 is that the apex angles of the isosceles trapezoid are all provided with an arc-shaped excessively arc-shaped surface 5, the A dimension is 0.6mm, the B dimension is 1.5mm, and the C dimension is 0.05mm. The fillet radius of the arc surface 5 is 0.75mm. In this embodiment, the solder is B25AgCuZn solder, and the specification before welding is 4x6x0.08mm; the welding method of the solder is high-frequency induction welding, and the welding coil is square, and the coil is heated in the middle of the contact bridge 1 during welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Cross section width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com