Wellhead stabilizing device for ocean drilling construction

A stabilizing device, marine technology, applied in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve the problems of long time for conduit injection and waiting for conduit to be stabilized, high construction cost, and high conduit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

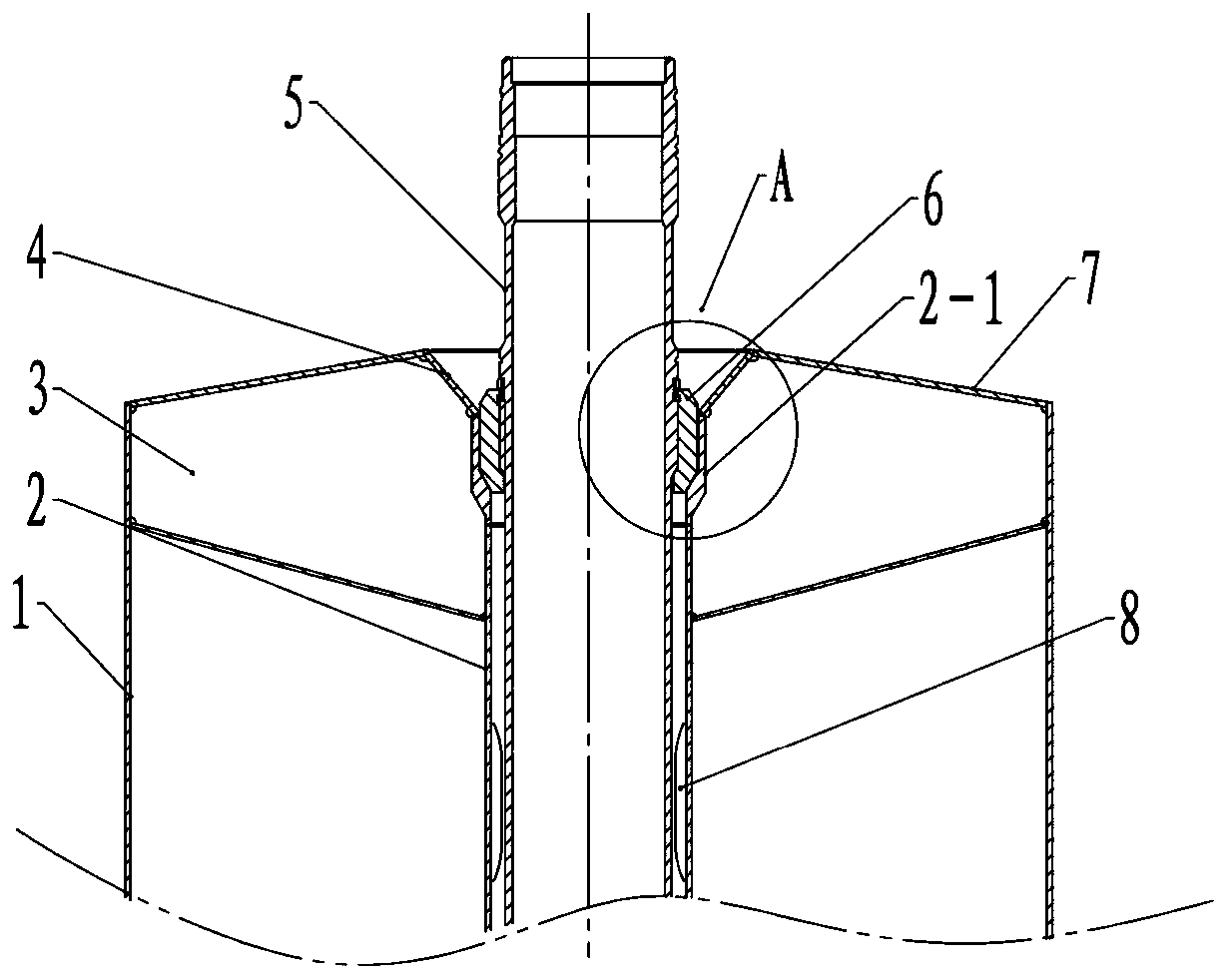

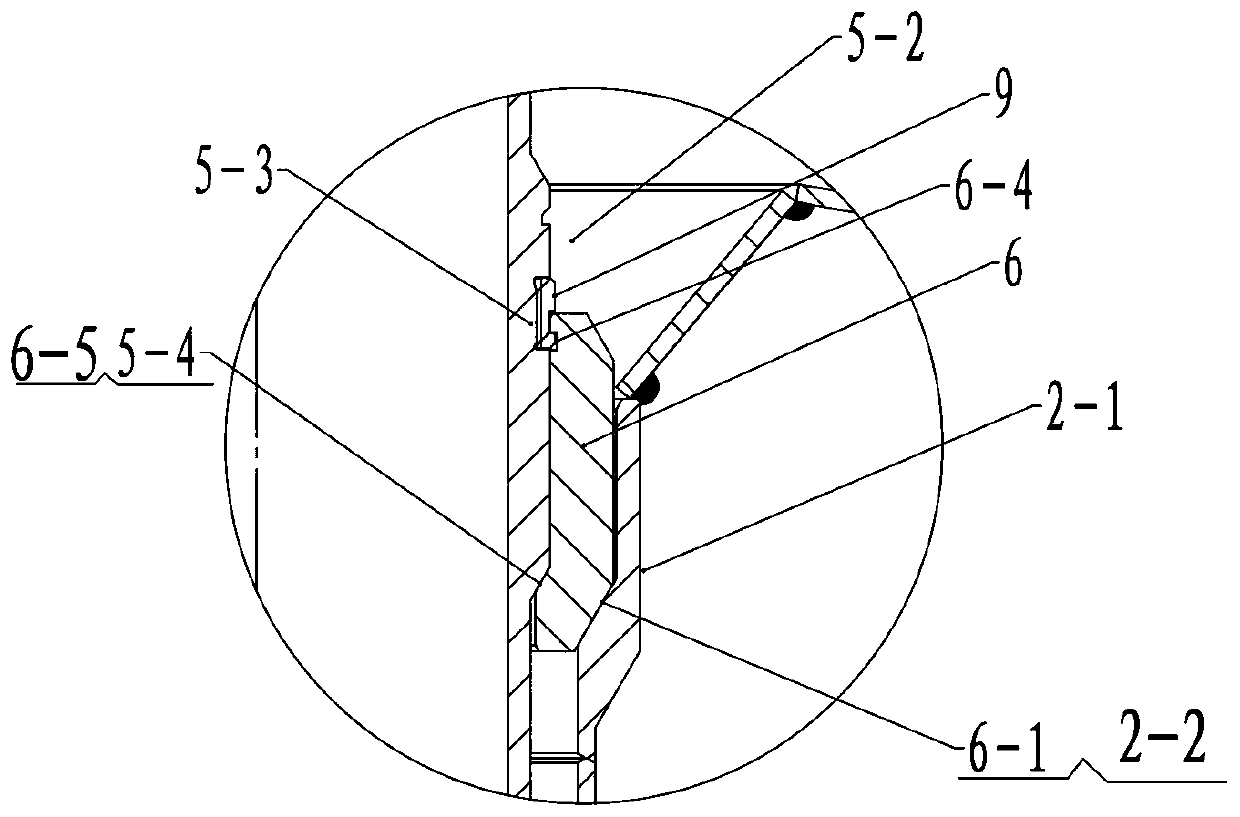

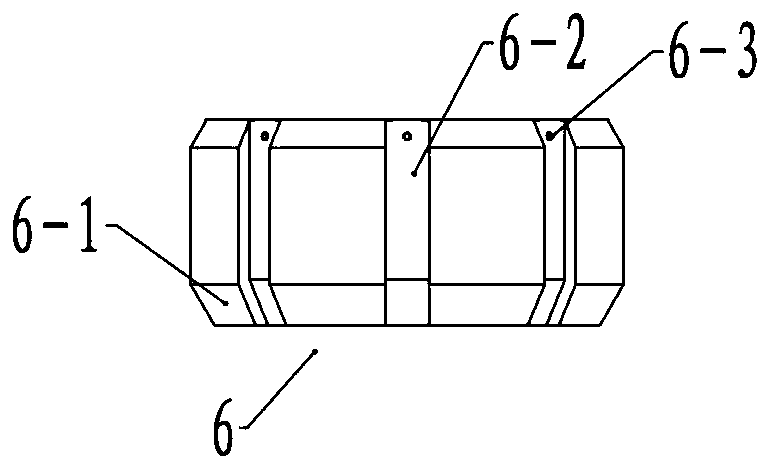

[0022] see figure 1 , Figure 5 and Figure 6 , the present invention includes a suction anchor and a conduit 5. The suction anchor consists of an inner tube 2 and an outer tube 1 to form a double-layer cylinder structure, and the conduit is located in the inner tube. Several ribs 3 are evenly distributed on the upper part of the suction anchor. The ribs are trapezoidal plates. The tubes are welded to improve the stability of the suction anchor and the connection strength of the inner and outer tubes. The annular area between the outer tube and the top of the inner tube is closed by the top plate 7, which is a conical surface to improve the pressure resistance. The top of the inner tube is provided with a transition bell mouth 4, the upper edge of the transition bell mouth is welded with the top plate, and the transition bell mouth is lower. The edge is welded to the top of the upper seat ring. The conduit 5 is a tubular structure, and the thick part at the top of the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com