Self-repairing linear polyurethane and preparation method thereof

A linear polyurethane self-healing technology, applied in the field of polymer materials, can solve the problems of increasing the consumption of polyurethane raw materials, easily producing cracked appearance, and destroying the ecological environment, etc., and achieves the effects of wide range of use effects, long service life, and protection of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

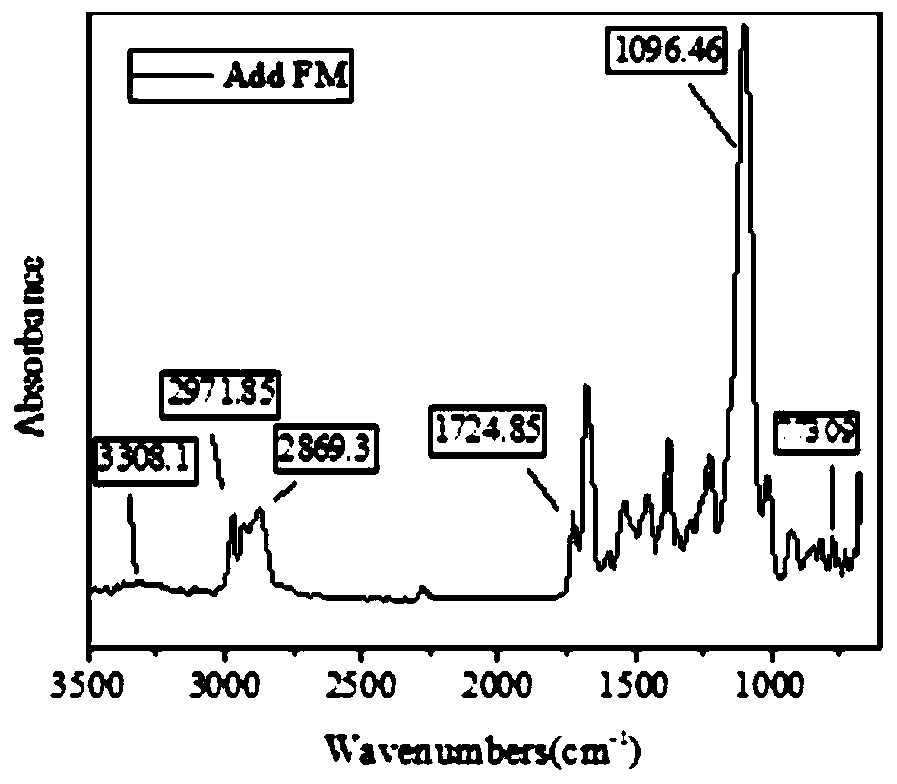

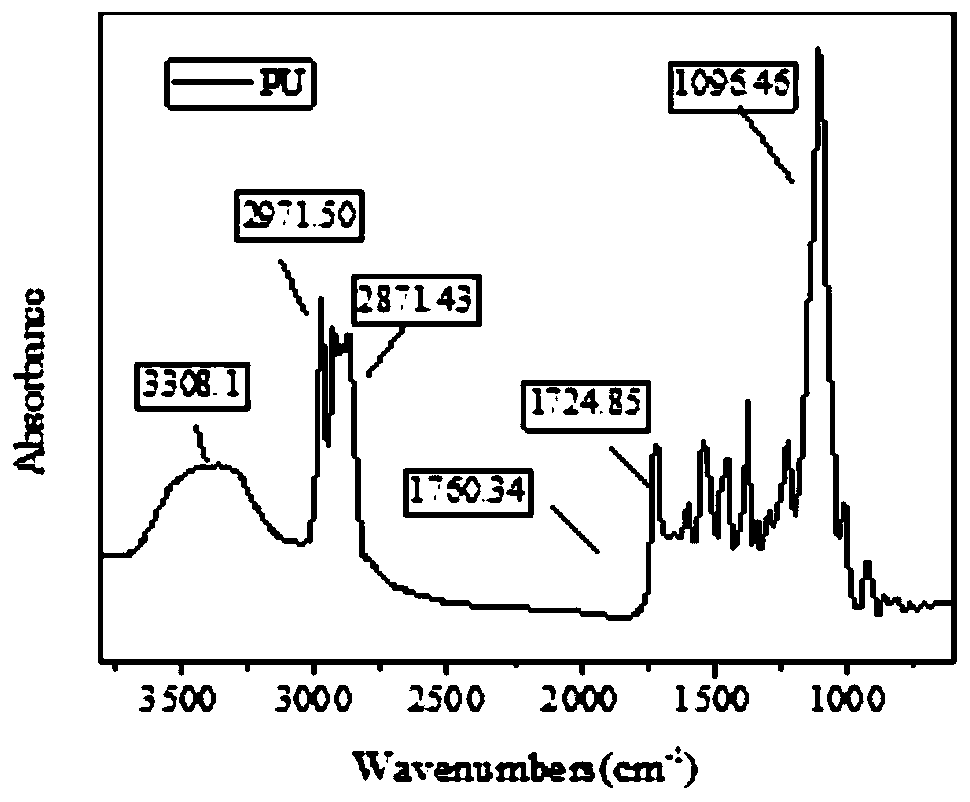

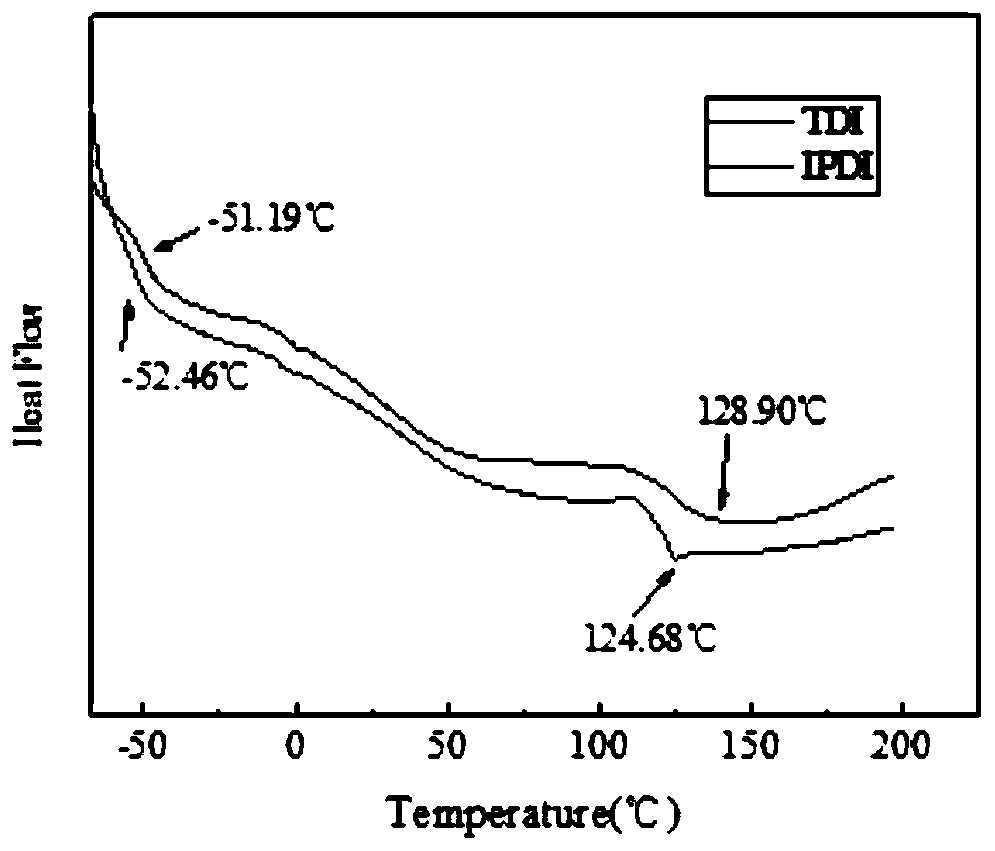

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing self-healing linear polyurethane, comprising the following steps:

[0045] S1. Place the polypropylene glycol at 120°C for 2 hours in a vacuum, dry the DMF over anhydrous magnesium sulfate, take 15g of polypropylene glycol, add it to a four-necked round-bottomed flask, pass nitrogen gas into the four-necked round-bottomed flask, and then take 10g of TDI was added to 5ml of DMF, heated to 50°C to dissolve, and the solution was obtained after the TDI was completely melted.

[0046] S2. Add PPG with a number average molecular weight of 2000 to the dissolving solution obtained in step S1 according to the ratio of group n-NCO to group n-OH of 2.0. Under protection, the reaction was stirred for 15 min to obtain an intermediate, which has -NCO capping. The end point of the reaction was determined by the toluene-di-n-butylamine method. When the -NCO group content reaches the theoretical value, it can be judged that the end of th...

Embodiment 2

[0053] This embodiment provides a method for preparing self-healing linear polyurethane, comprising the following steps:

[0054] S1. Place the polypropylene glycol at 120°C for 2 hours in a vacuum, dry the DMF over anhydrous magnesium sulfate, take 15g of polypropylene glycol, add it to a four-necked round-bottomed flask, pass nitrogen gas into the four-necked round-bottomed flask, and then take Add 10g of TDI to 5ml of DMF and heat to 55°C to dissolve. After the TDI is completely melted, a solution is obtained.

[0055] S2. Add PPG with a number average molecular weight of 2000 to the dissolving solution obtained in step S1 according to the ratio of group n-NCO to group n-OH of 2.0, the amount of PPG added is 40g, the temperature is raised to 70°C, Under protection, the reaction was stirred for 15 min to obtain an intermediate, which has -NCO capping. The end point of the reaction was determined by the toluene-di-n-butylamine method. When the -NCO group content reaches the...

Embodiment 3

[0062] This embodiment provides a method for preparing self-healing linear polyurethane, comprising the following steps:

[0063] S1. Place the polypropylene glycol at 120°C for 2 hours in a vacuum, dry the DMF over anhydrous magnesium sulfate, take 15g of polypropylene glycol, add it to a four-necked round-bottomed flask, pass nitrogen gas into the four-necked round-bottomed flask, and then take 10g of TDI was added to 5ml of DMF, heated to 45°C to dissolve, and the solution was obtained after the TDI was completely melted.

[0064] S2. Add PPG with a number average molecular weight of 2000 to the dissolving solution obtained in step S1 according to the ratio of group n-NCO to group n-OH of 2.0. Under protection, the reaction was stirred for 14 minutes to obtain an intermediate, which has an -NCO capping group. The end point of the reaction was determined by the toluene-di-n-butylamine method. When the -NCO group content reaches the theoretical value, it can be judged that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com