C80 concrete, concrete filled steel tube and preparation method thereof

A technology of concrete and mixture, which is applied in the field of building materials, can solve the problems of long initial setting time and unsatisfactory conditions, and achieve the effects of good pumping performance, moderate viscosity, micro-expansion compensation shrinkage and super long initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] prepare concrete

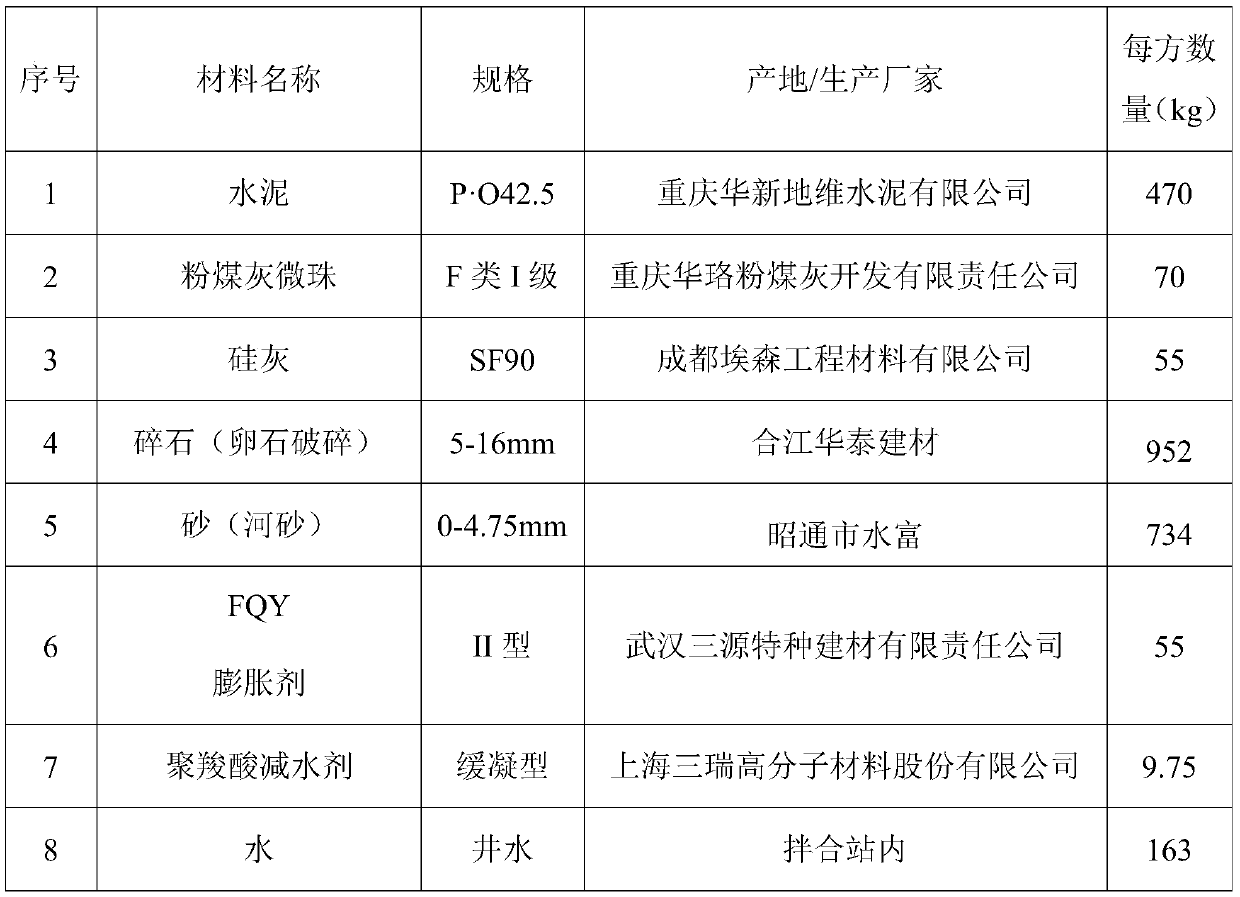

[0035] Raw materials:

[0036] Cement: Chongqing Huaxin Diwei Cement Co., Ltd., ordinary Portland cement P.O 42.5.

[0037] Sand: Mount Emei, the place of origin, fineness modulus 2.98, apparent density 2926kg / m 3 , stone powder content 7.9%, crushing value 7%, 7%, 11%, 12%.

[0038] Crushed stone: Mount Emei, the place of origin, 5-16mm continuous gradation (the ratio of 5-10mm particle size to 10-16mm particle size is 3:7), apparent density 2951kg / m 3 , crushing value 13.9%, mud content 0.4, mud block content 0%, needle flake 0%, parent rock compressive strength 168MPa.

[0039] Water reducer: Shanghai Sanrui Polymer Materials Co., Ltd., polycarboxylate high-performance water reducer; 2 / 10,000 to 3 / 10,000 air-entraining agent is added to the polycarboxylate high-performance water reducer agent.

[0040] Expansion agent: Wuhan Sanyuan Special Building Materials Co., Ltd., FQY high-performance expansion agent; the main components of the FQY high-...

Embodiment 2

[0054] The C80 concrete filled steel pipe prepared in Example 1 was used to pour the main arch of a highway bridge in Hejiang.

[0055] Before the concrete is poured, the surface of the pump pipe is covered with cotton cloth. During the pouring process, water is sprinkled on the cotton cloth to keep the cotton cloth covering the pump pipe in a wet state.

[0056] The particle size of gravel (pebble) shall not be greater than 1 / 3 of the diameter of the pump pipe. Use a shaping machine to shape the gravel (pebble) to make the particle shape of the gravel (pebble) regular, and reduce the relative movement of concrete when pumping concrete resulting pumping resistance.

[0057] The prepared C80 concrete has excellent pumping performance. It adopts a three-stage relay pouring process. The vertical height of jacking pouring reaches 150m, the arc length of the main arch (half arch) is 380m, and the ambient temperature during pouring reaches 28℃~35℃. The time is 12 hours, the pumping...

Embodiment 3-6

[0059] Carry out C80 steel tube concrete mixing in the same concrete mixing station as embodiment 1, the source of raw material composition purchasing used for mixing is identical with embodiment 1, and the addition application weight of various raw material composition is as shown in table 3.

[0060] Table 3 Example 3-6 Stirring of C80 concrete-filled steel pipe concrete to add raw material components Quantity per square meter (kg)

[0061]

[0062]

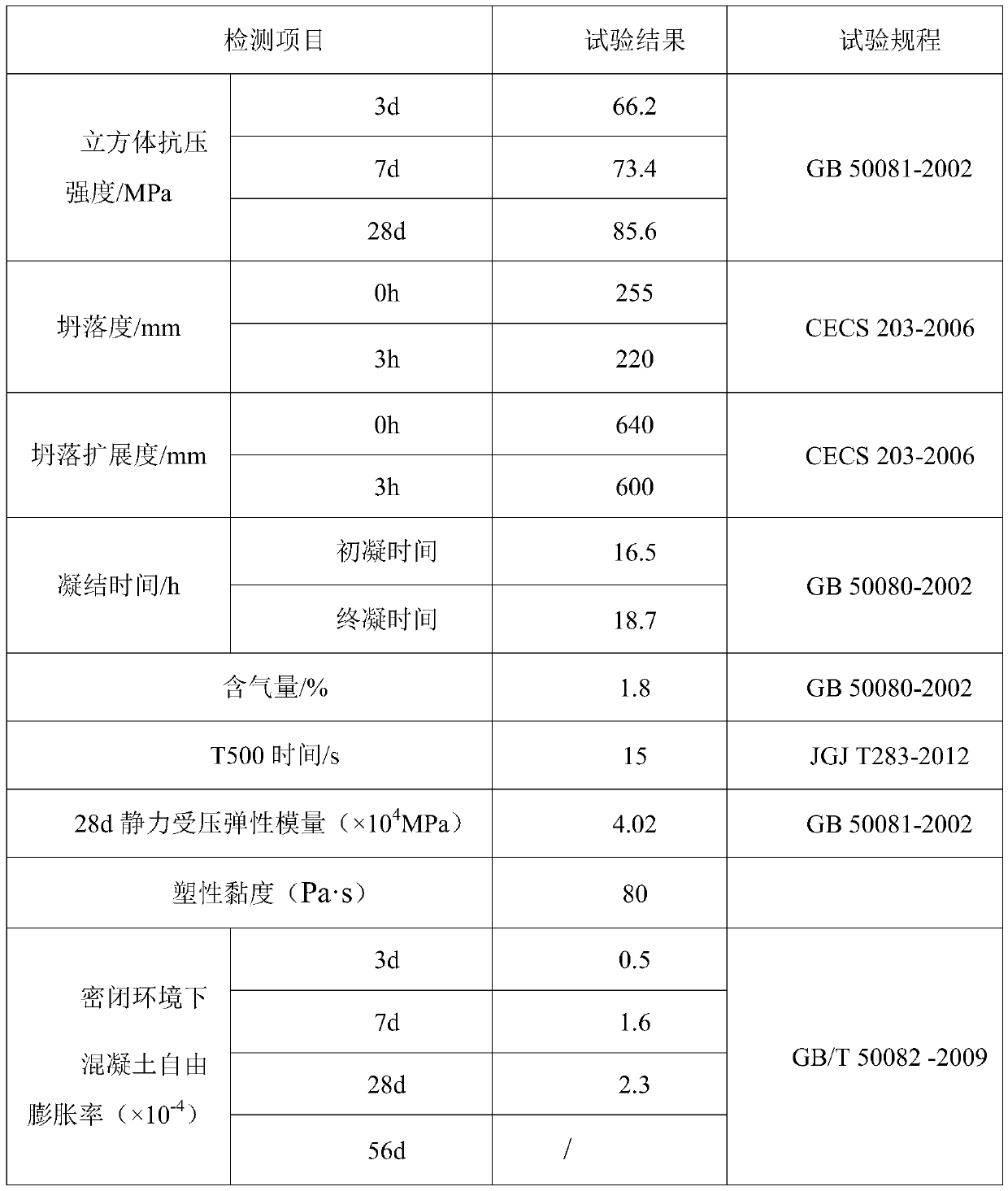

[0063] According to the same method (test procedure) as in Example 1, the mixing preparation of C80 concrete was carried out, and the test results are shown in Table 4.

[0064] Table 4 Example 3-6 prepares the performance test of C80 concrete filled steel pipe

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com