Variable-crumple-force crumpling mechanism for steering column

A steering column and collapse technology, which is applied to the steering mechanism, steering column, and steering control installed on the vehicle, can solve the problem that the steering column cannot provide collapse force and absorb energy, and achieve a large range of collapse force , increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. The following descriptions are exemplary and not limiting to the present invention. Any other similar situations also fall within the protection scope of the present invention.

[0026] In the following detailed description, directional terms, such as "left", "right", "upper", "lower", "front", "rear", etc., are used with reference to directions described in the drawings. Components of embodiments of the present invention may be positioned in a variety of different orientations, and directional terms are used for purposes of illustration and not limitation.

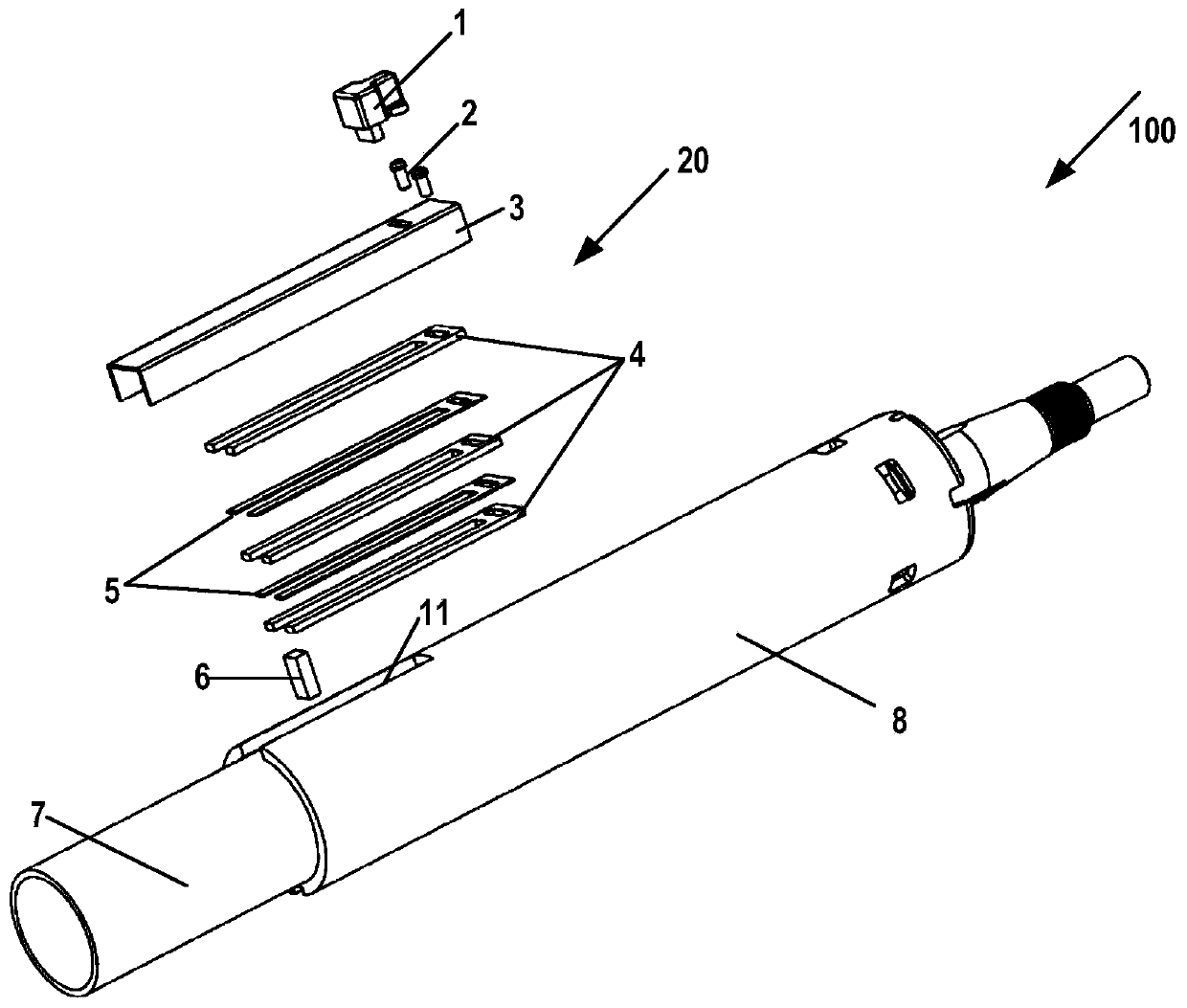

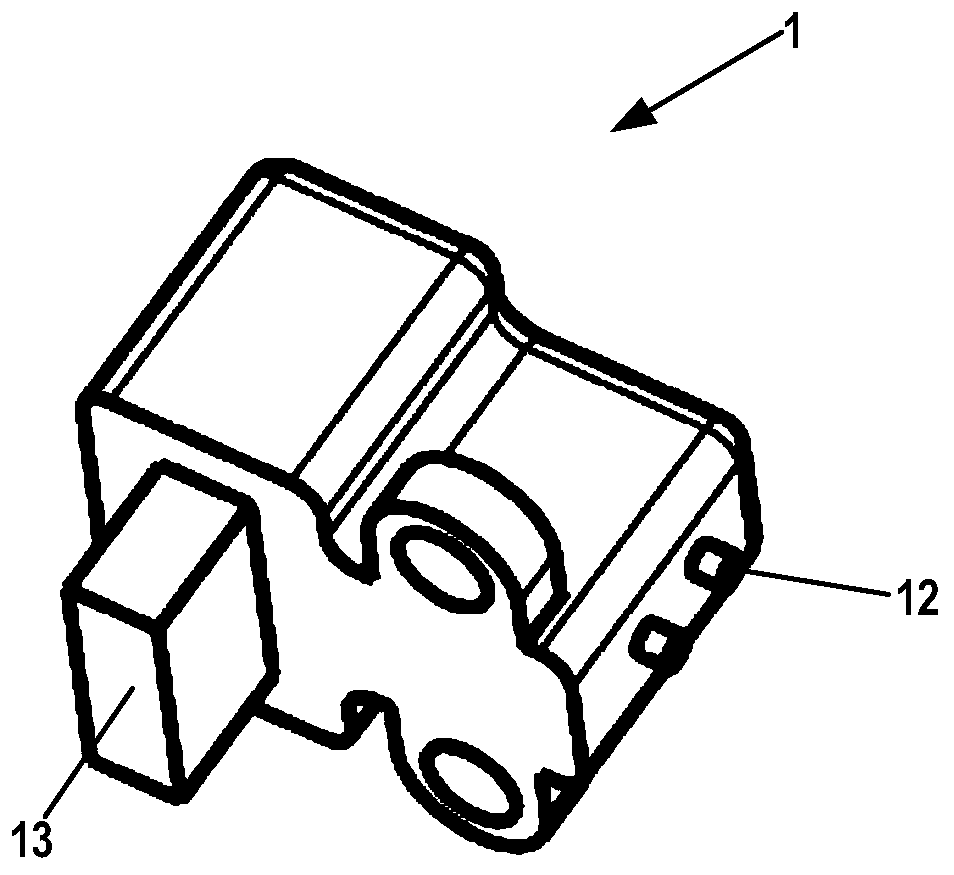

[0027] figure 1 A schematic perspective view of the outer sleeve 100 of the assembled steering column is shown. In this case, the outer sleeve 100 has a coaxially arranged, non-rotatable inner tube 7 and an outer tube 8 , which at least partially surround the inner tube 7 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com